Overview

Sand Washing Plant Introduction

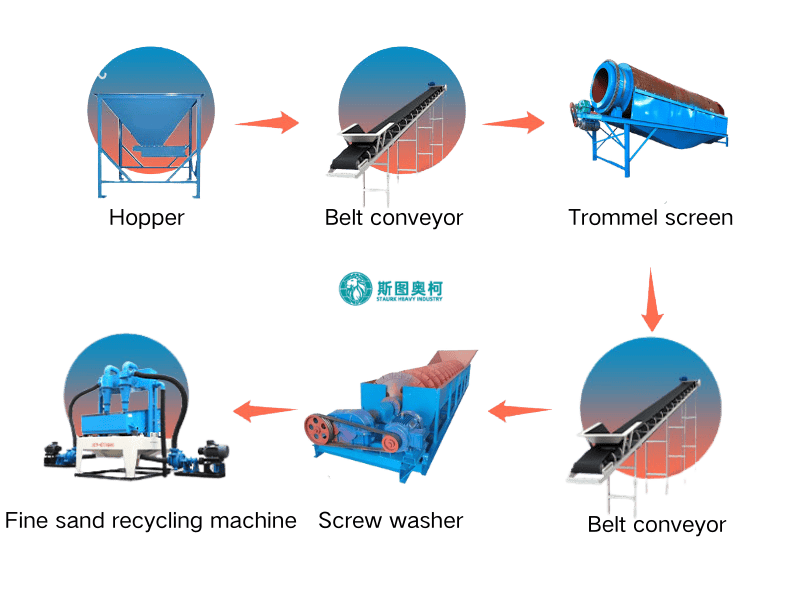

This sand washing production line begins with raw material being fed from a hopper onto a belt conveyor that transports it into a trommel screen where rotating drum action and high-pressure water sprays remove oversized debris (>5mm) and classify the material, after which the screened sand (0-5mm) is conveyed via another belt conveyor to a screw sand washer where counter-rotating screw blades vigorously agitate the sand in a water bath to scrub away residual clay and impurities through intense friction, with the cleaned sand then discharged while wastewater containing fine particles flows to a settling tank or hydrocyclone system for fine sand recovery and water recycling, ensuring high-purity sand output.

Sand Washing Plant Working Principle

1.Material Feeding

Raw sand or aggregates are discharged from the storage hopper onto a belt conveyor, which ensures a controlled and uniform feed rate into the trommel screen.

2.Trommel Screening & Pre-Washing

The rotating trommel screen uses a combination of: Mechanical tumbling: Breaks up clumps and removes debris (>5mm).

High-pressure water sprays: Pre-washes the material, removing loose clay and dust.

Properly sized sand (0-5mm) passes through the screen apertures, while oversized waste is discharged separately.

3.Sand Conveyance to Screw Washer

A second belt conveyor transports the screened sand into the screw sand washer, ensuring a steady flow without clogging.

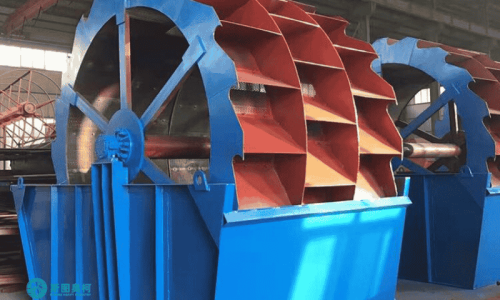

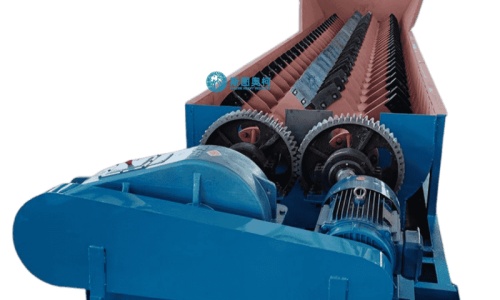

4.Intensive Washing in Screw Washer

The rotating screw creates a turbulent water bath, where:

Hydraulic shear forces strip away stubborn clay and contaminants.

Inter-particle friction further scrubs the sand surfaces.

Gravity separation allows clean sand to settle, while lighter impurities overflow.

5.Discharge & Water Management

Washed sand exits with controlled moisture (≤15%).

Wastewater (carrying fine particles <0.075mm) flows to a settling tank or hydrocyclone for:

Fine sand recovery (up to 90% of 0.075–0.5mm particles).

Water recycling (80% reuse rate, minimizing freshwater intake).

6.Automation & Control

PLC systems regulate feed rates, water flow, and rotor speeds for consistent output quality (silt content ≤3%).

Sand Washing Plant Features

1.Automated & Continuous Operation

The system ensures smooth material flow from the hopper to the final product without manual intervention.

Belt conveyors maintain a steady feed rate for consistent processing.

2.Efficient Pre-Screening & Washing

The trommel screen separates oversized debris while pre-washing the material.

It effectively removes loose impurities before the sand enters the screw washer.

3.Thorough Cleaning in Screw Washer

The rotating screw mechanism creates strong agitation for deep scrubbing.

Sand particles are cleaned through friction and water shear forces.

4.Water Recycling & Environmental Protection

A closed-loop system recycles water, reducing consumption.

Settling tanks or hydrocyclones recover fine particles from wastewater.

5.High-Quality Output

Produces clean sand with low silt content and controlled moisture.

Suitable for construction, concrete, and industrial applications.

6.Durable & Low-Maintenance Design

Wear-resistant materials extend equipment lifespan.

Simple structure ensures easy operation and maintenance.

7.Compact & Flexible Configuration

Adaptable for different raw materials (river sand, crushed stone, recycled aggregates).

Can be scaled for small to large production needs.

8.User-Friendly Control

Automated systems monitor and adjust the process for optimal performance.

Minimal manual supervision required.