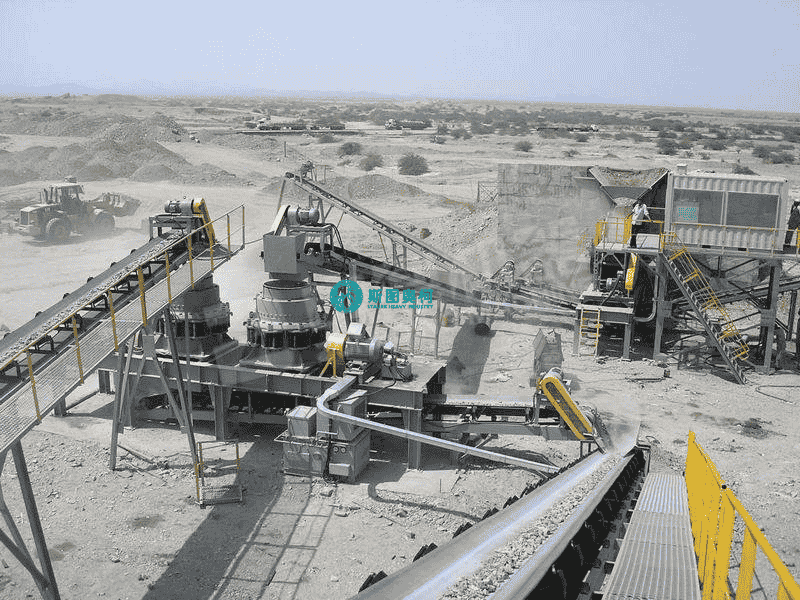

Overview

Granite Crushing Production Line Introduction

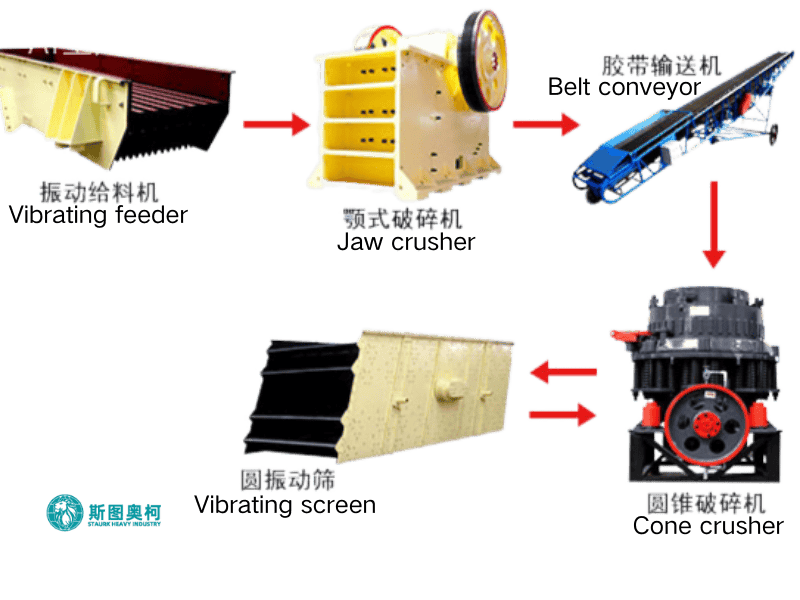

This granite crushing production line with a processing capacity of 200 tons per hour is a complete and efficient system specifically designed for hard rock processing. The entire process begins with raw granite being uniformly fed into the system through a heavy-duty vibrating feeder, which ensures consistent material flow and prevents bridging or blockage. The material then enters the primary crushing stage where a robust jaw crusher performs initial size reduction, breaking down large granite blocks into manageable 150-300mm pieces.

The crushed material is then conveyed to the secondary processing stage featuring a high-performance cone crusher that further reduces the particle size to below 40mm through its advanced crushing chamber design and precise adjustment system. Following secondary crushing, the material undergoes precise classification via a multi-deck vibrating screen equipped with specially designed screen meshes to separate the product into various required specifications (typically 0-5mm, 5-10mm, 10-20mm, and 20-40mm).

This intelligent closed-circuit crushing system automatically recirculates oversized materials back to the cone crusher for reprocessing, guaranteeing optimal efficiency and consistent product quality. Featuring advanced automation that monitors and adjusts operations in real-time, the production line maintains peak performance while protecting equipment. Its wear-resistant design utilizes high-grade manganese steel components to withstand granite's abrasiveness, complemented by integrated dust control and noise reduction systems. This comprehensive solution delivers reliable, high-quality granite processing with maximum operational efficiency.

Granite Crushing Production Line Application

The stone crushing line is widely applicable in various industries including infrastructure construction for producing highway subbase materials and railway ballast, building construction for manufacturing high-quality concrete aggregates, water conservancy projects for breakwater and revetment stones, municipal engineering for paving slabs and curbstones, as well as commercial concrete plants requiring precisely graded 5-40mm aggregates, with its closed-loop design particularly suitable for major projects demanding superior particle shape and compressive strength such as bridge construction and airport runways where high-performance base materials are essential.

Granite Crushing Production Line Working principle

1.Controlled Material Feeding

The process begins with a vibrating feeder that regulates the 200 t/h granite flow into the jaw crusher. This ensures steady, even feeding for optimal primary crushing efficiency while preventing equipment overload.

2.Two-Stage Size Reduction

First, the jaw crusher performs coarse crushing, breaking large granite blocks (typically 500-800mm) down to 150-300mm. Then the cone crusher further reduces material to under 40mm through compressive crushing, ideal for granite's hardness.

3.Precision Screening System

A vibrating screen accurately classifies crushed material. Properly sized aggregates (0-5mm, 5-20mm etc.) proceed as final product while oversized pieces are automatically detected and recirculated.

4.Efficient Closed-Circuit Operation

The system's intelligence lies in its return loop - oversized material automatically re-enters the cone crusher via conveyor. This closed-circuit design maximizes yield and ensures consistent product sizing with minimal waste.

5.Automated Process Control

Integrated sensors and control systems monitor and adjust the entire operation in real-time. From feeder speed to crusher settings, automation maintains optimal 200 t/h throughput while protecting equipment.

6.Hard Material Optimization

Specially designed wear parts (mantles, concaves, jaw plates) withstand granite's abrasiveness. Crusher settings are precisely calibrated for granite characteristics, balancing production and wear life.

Granite Crushing Production Line Features

1.Two-Stage Crushing Process

The granite is first crushed by a jaw crusher (primary) and then further processed by a cone crusher (secondary) for finer fragmentation.

2.Closed-Circuit Screening System

A vibrating screen separates the crushed material; oversized particles are returned to the cone crusher for re-crushing, ensuring high efficiency and product uniformity.

3.Optimized for Hard Abrasive Material

The line is designed for granite (high hardness & abrasiveness), utilizing robust jaw and cone crushers for wear resistance and stable 200 t/h output.

4.Automated & Continuous Operation

The vibrating feeder ensures consistent material flow, while the closed-loop design minimizes manual intervention, enhancing productivity and consistency.