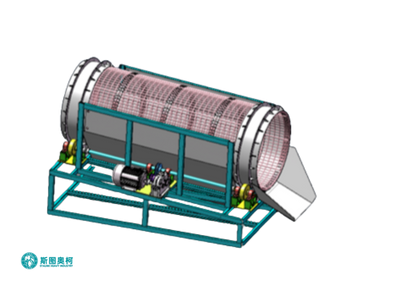

Trommel Screen

Capacity: 10-300TPH

Feeding Size: ≤150mm

Discharging Size: 0-50mm

Handling Materials: Soil, compost, aggregates, municipal waste, and minerals, etc

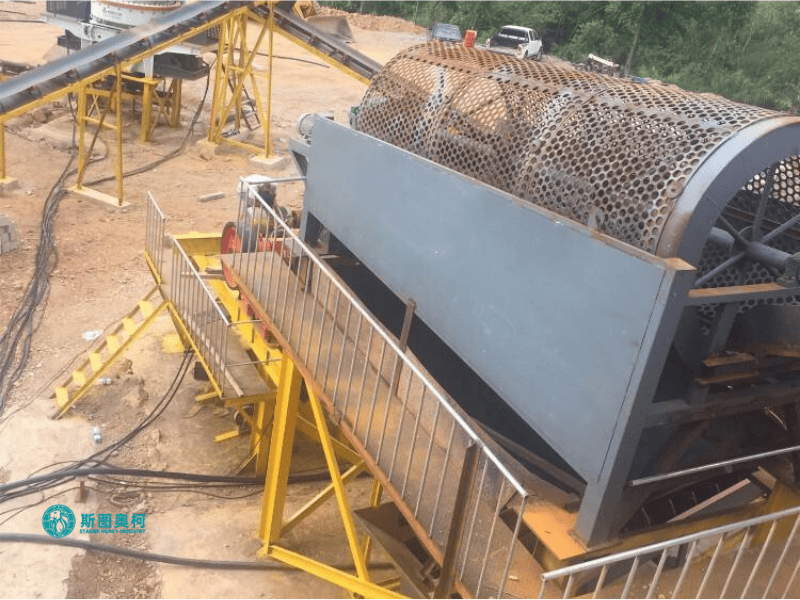

A trommel screen separates mixed materials (e.g., soil, compost, waste) by size using a rotating cylindrical drum with mesh panels. Ideal for recycling, mining, and agriculture, it offers adjustable screening sizes, high throughput, and robust performance. Handles wet/dry feed but struggles with sticky substances.

Advantages

01.

High Efficiency

Handles large volumes (10-300t/h) with continuous operation, ideal for bulk material sorting like compost or aggregates.

02.

Adjustable Separation

Customizable screen mesh (1-100mm) enables precise size separation for diverse materials and applications.

03.

Low Maintenance

Simple rotating drum design minimizes wear parts, reducing downtime and operational costs.

04.

Versatile Feed

Processes wet/dry materials, from sand to municipal waste, though sticky substances may require pre-treatment.

How Does A Trommel Screen Work

1. Material Loading: Mixed feedstock (soil, waste) is fed into the inclined rotating drum via a hopper or conveyor.

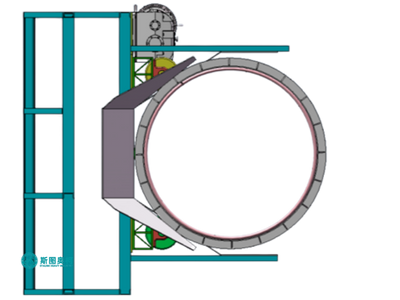

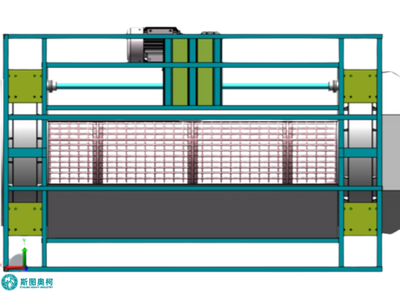

2. Rotation & Tumbling: The motor-driven drum rotates (5–25 RPM), causing materials to cascade and tumble, breaking up clumps for better separation.

3. Size Classification: Smaller particles pass through screen apertures (1–100mm), while oversized materials travel along the drum’s length due to gravity and inclination (2°–5°).

4. Discharge Zones: Screened fractions exit via separate chutes: fines (undersize) collect beneath the drum; oversize discharges from the drum’s end for further processing.

Applications

Models

Model | Drum Diameter (mm) | Drum Length (mm) | Mesh Size (mm) | Power (kW) | Capacity (t/h) | Rotation Speed (rpm) | Inclination Angle (°) |

TS-600 | 600 | 1500 | 5-100 | 1.5-2.2 | 5-15 | 10-20 | 2-5 |

TS-800 | 800 | 2000 | 5-100 | 2.2-3.7 | 10-25 | 10-20 | 2-5 |

TS-1000 | 1000 | 2500 | 5-100 | 3.0-5.5 | 20-40 | 10-20 | 2-5 |

TS-1200 | 1200 | 3000 | 5-100 | 4.0-7.5 | 30-60 | 10-20 | 2-5 |

TS-1500 | 1500 | 4000 | 5-100 | 5.5-11.0 | 50-100 | 10-20 | 2-5 |

TS-1800 | 1800 | 5000 | 5-100 | 7.5-15.0 | 80-150 | 10-20 | 2-5 |