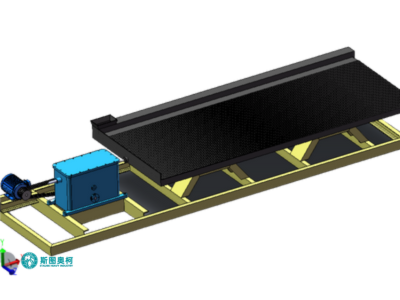

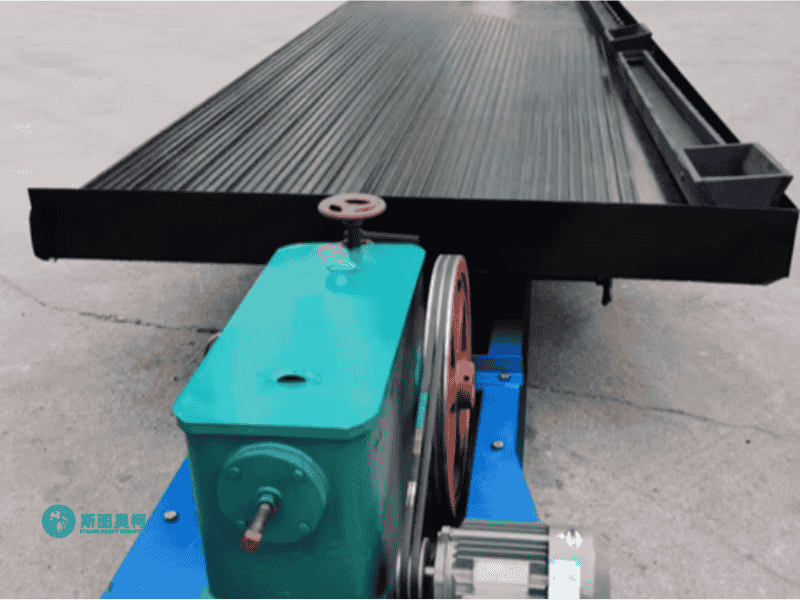

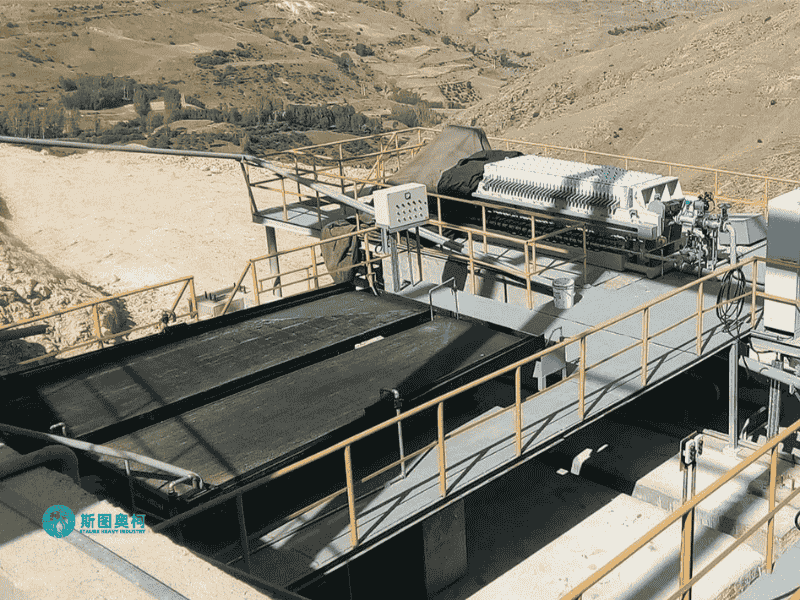

Shaking Table

Capacity: 0.1-3 TPH

Feeding Size: 0.02-2 mm

Discharging Size: 80–95%(>0.1 mm),60–80%(0.02–0.1 mm)

Handling Materials: Tungsten ore, tin ore, tantalum ore, niobium ore, gold ore, zircon, chromite, etc.

Shaking table recovers heavy minerals (e.g., tungsten, gold) from 0.02–2mm ore using rhythmic shaking and water flow. It achieves 10–100x enrichment with 60–95% recovery at 0.1–3t/h capacity. Ideal for final concentration but requires low-clay feeds.

Advantages

01.

High Precision

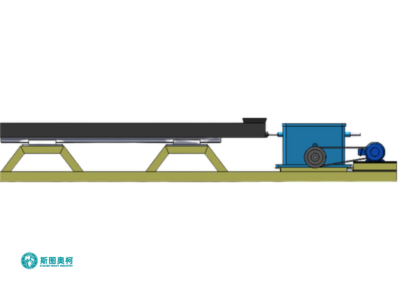

Separates minerals with density differences as low as 0.1g/cm³ (tungsten/quartz) via adjustable shaking and water flow control.

02.

No Reagents

Environmentally friendly gravity concentration without chemicals, ideal for clean mineral processing circuits.

03.

Easy Operation

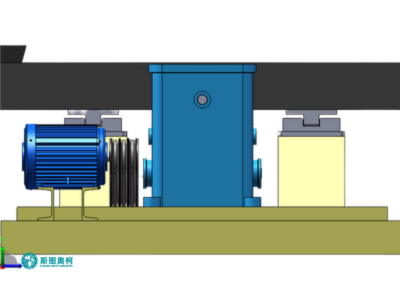

Simple adjustments to deck angle (2°–5°) and water flow (5–15L/min) optimize grade/recovery balance.

04.

Low Energy

Consumes only 0.5–2kW per table, making it cost-effective for small-scale or final concentration stages.

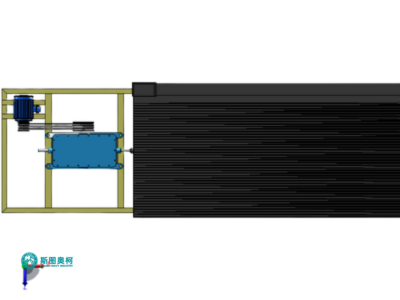

How Does A Shaking Table Work

1. Feed Distribution: Ore slurry (20–30% solids, 0.02–2 mm) enters the inclined deck through a feed box, forming a thin layer across riffles.

2. Stratification: Longitudinal shaking (200–300 RPM) and transverse water flow separate particles by density, pushing heavies (gold) toward the riffles while washing lights downstream.

3. Band Formation: Differential movement creates distinct mineral bands: high-density particles climb riffles to the concentrate zone, mid-densities form middlings, and gangue reports to tailings.

4. Product Discharge: Adjustable splitters divide the deck into concentrate (10–100x enriched), middlings (recycled), and tailings (≤1% target mineral).

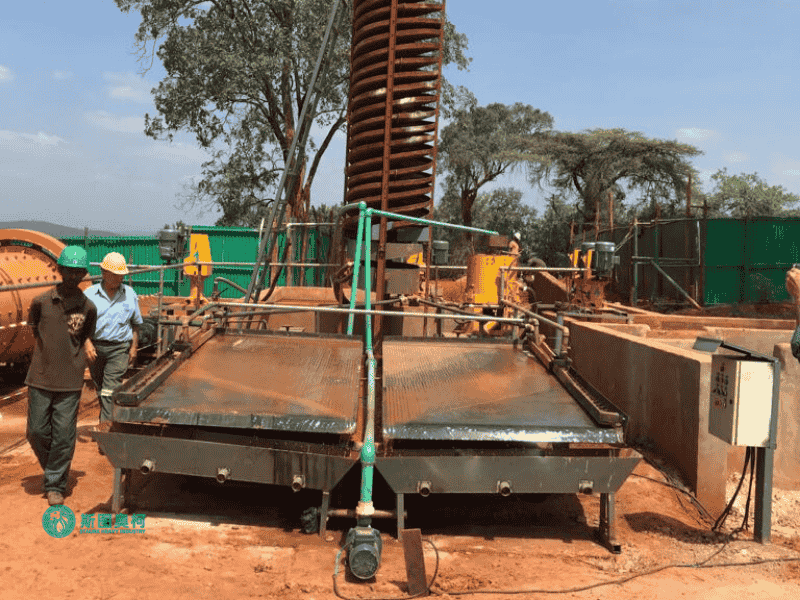

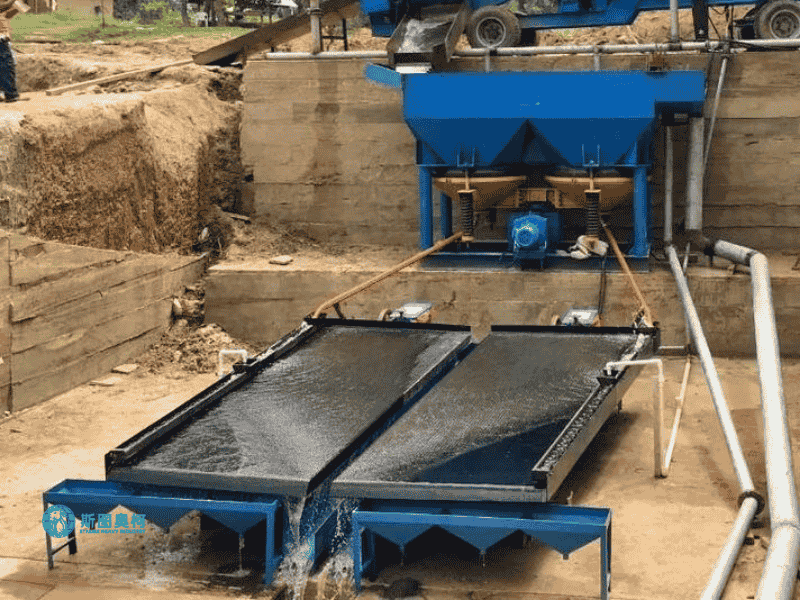

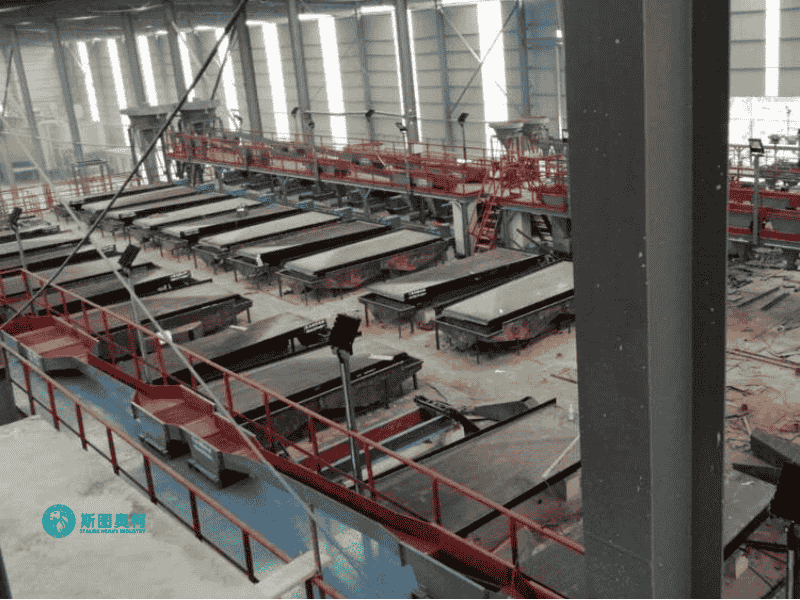

Applications

Models

Model | Deck Size (mm) | Capacity (TPH) | Stroke Length (mm) | Power (kW) | Weight (kg) | Dimensions (L x W x H, mm) | Application |

ST-1000 | 1,000 x 500 | 0.5-1.0 | 10-20 | 1.1 | 200 | 1,200 x 600 x 800 | Small-scale mineral separation |

ST-1500 | 1,500 x 750 | 1.0-2.0 | 15-25 | 1.5 | 300 | 1,800 x 900 x 1,000 | Medium-scale ore processing |

ST-2000 | 2,000 x 1,000 | 2.0-3.0 | 20-30 | 2.2 | 500 | 2,500 x 1,200 x 1,200 | Large-scale mining operations |

ST-2500 | 2,500 x 1,250 | 3.0-4.0 | 25-35 | 3.0 | 700 | 3,000 x 1,500 x 1,500 | Industrial mineral processing |

ST-3000 | 3,000 x 1,500 | 4.0-5.0 | 30-40 | 4.0 | 1,000 | 3,500 x 1,800 x 1,800 | Heavy-duty mining applications |