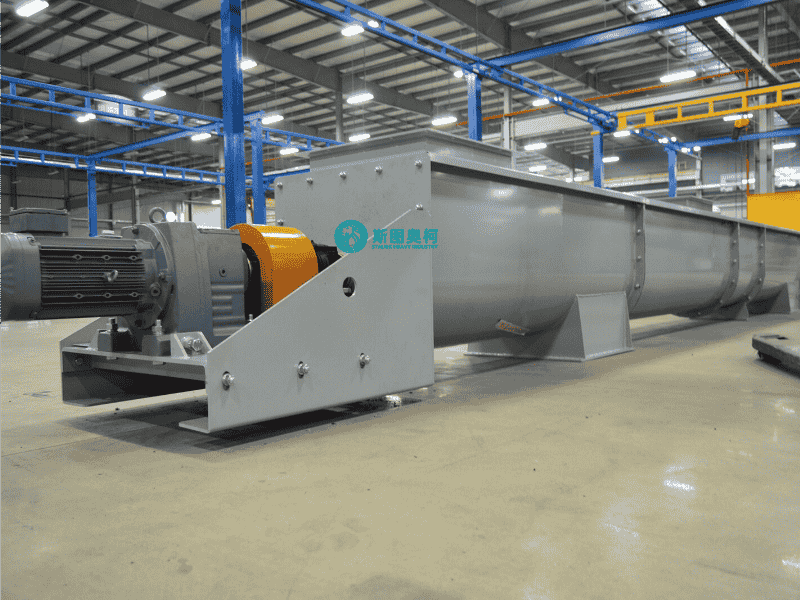

Screw Conveyor

Capacity: 1-300 TPH

Feeding Size: 0-50 mm

Discharging Size: 0-50 mm

Handling Materials: Biomass particles, crushed ore, sludge, wet clay, cement, etc

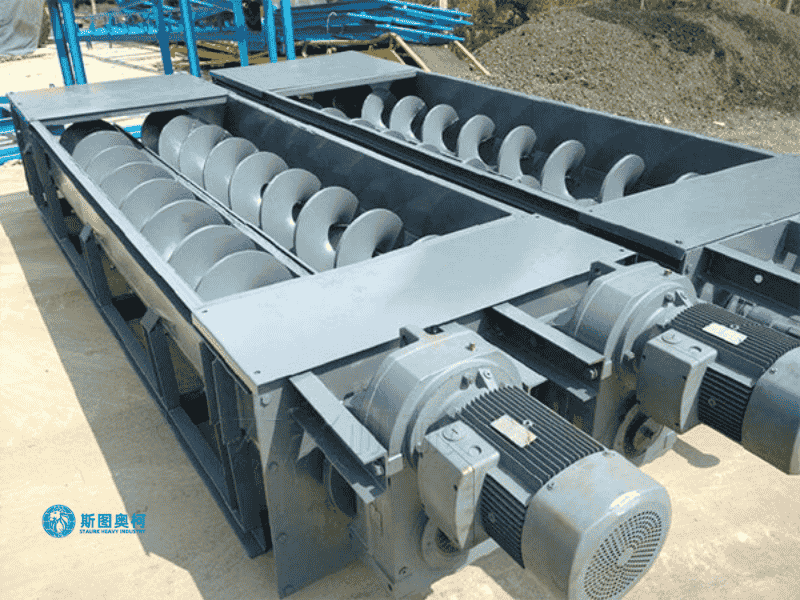

A screw conveyor is a mechanical system that moves bulk materials using a rotating helical blade inside a trough. It efficiently transports powders, granules, or semi-solids horizontally, vertically, or at an incline. Its simple design ensures low maintenance, while its versatility suits industries like agriculture, food processing, and construction. Ideal for continuous, controlled material flow with minimal energy consumption.

Advantages

01.

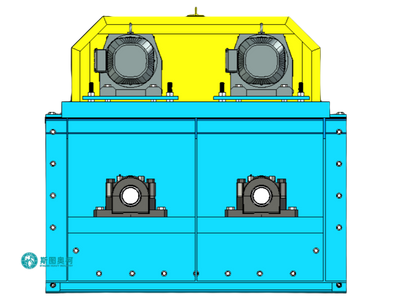

Simple Structure

Compact design with few moving parts, ensuring easy installation and low maintenance requirements.

02.

High Efficiency

Continuous material flow with minimal energy loss, ideal for uniform feeding and precise discharge control.

03.

Versatile Handling

Suitable for powders, granules, and semi-solids, adaptable to various industries like food, chemicals, and construction.

04.

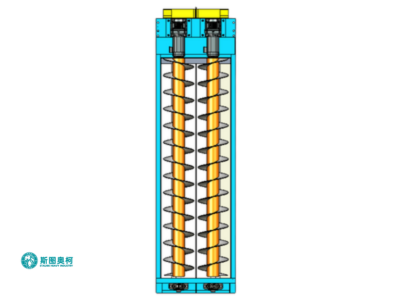

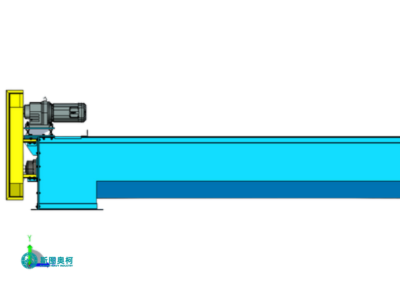

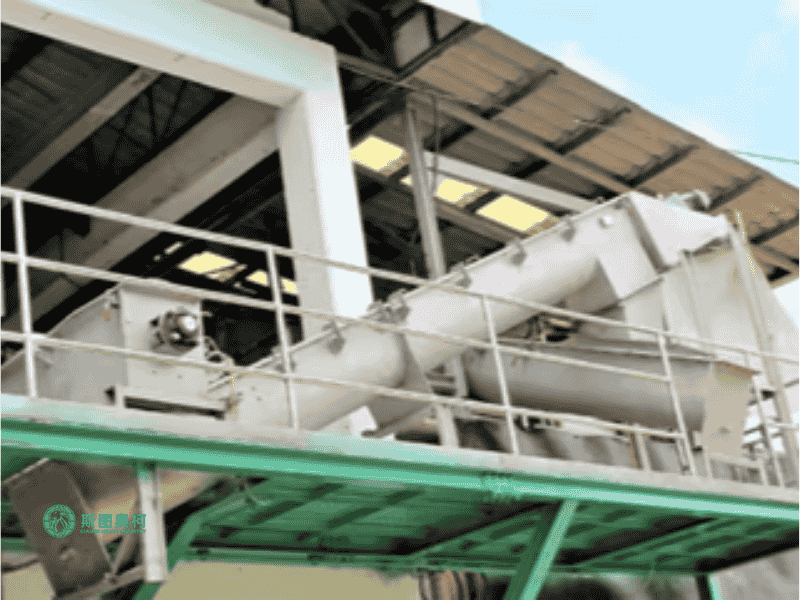

Space-Saving

Horizontal, inclined, or vertical layouts optimize space usage, fitting into tight production areas efficiently.

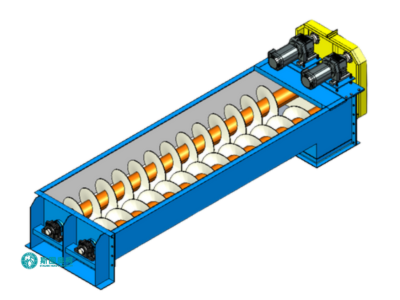

How Does A Screw Conveyor Work

1. Material Loading: Material is fed into the conveyor through an inlet, typically via gravity or another feeding mechanism.

2. Screw Rotation: A rotating helical screw blade (auger) moves the material along the trough. The screw’s pitch and speed determine the flow rate.

3. Material Transport: As the screw turns, material is pushed forward through the trough via the screw’s continuous helical motion, creating a steady flow.

4. Discharge: Material exits at the discharge point, either by gravity or through controlled mechanisms like gates or chutes.

Applications

Models

Model | Capacity (t/h) | Max. Length (m) | Screw Diameter (mm) | Speed (rpm) | Power (kW) | Material | Inclination (°) | Remarks |

SC150 | 5-10 | 10-20 | 150 | 50-100 | 1.5-3.0 | Powdery/Granular | <20 | Suitable for light materials like flour, grains, and powders. |

SC200 | 10-20 | 15-30 | 200 | 50-100 | 3.0-5.5 | Powdery/Granular | <20 | Ideal for medium-capacity handling of materials like cement and sand. |

SC300 | 20-50 | 20-40 | 300 | 50-100 | 5.5-7.5 | Granular/Abrasive | <20 | Designed for granular and mildly abrasive materials like gravel and ore. |

SC400 | 50-100 | 30-50 | 400 | 50-100 | 7.5-11 | Heavy Powdery/Granular | <20 | Suitable for heavy powdery materials like fly ash and cement. |

SC500 | 100-200 | 40-60 | 500 | 50-100 | 11-18.5 | Abrasive/Sticky | <20 | Ideal for abrasive or sticky materials like clay and wet sludge. |

SC600 | 200-300 | 50-70 | 600 | 50-100 | 18.5-22 | Heavy-Duty Materials | <20 | Designed for heavy-duty applications, such as mining and construction. |