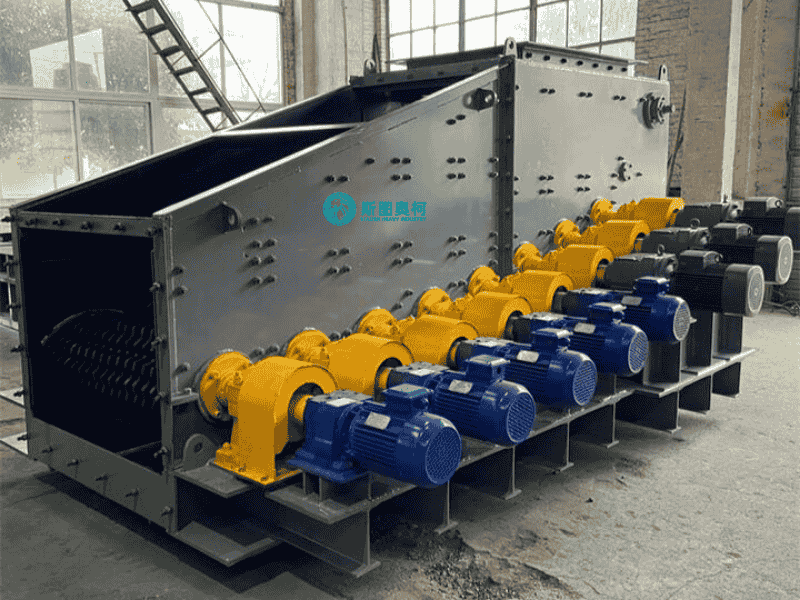

Roller Screen

Capacity: 30-1200 TPH

Feeding Size: ≤150-800 mm

Discharging Size: 5-300mm

Handling Materials: Mining material, sand and gravel aggregates, coal and soil stone separation, construction waste, etc

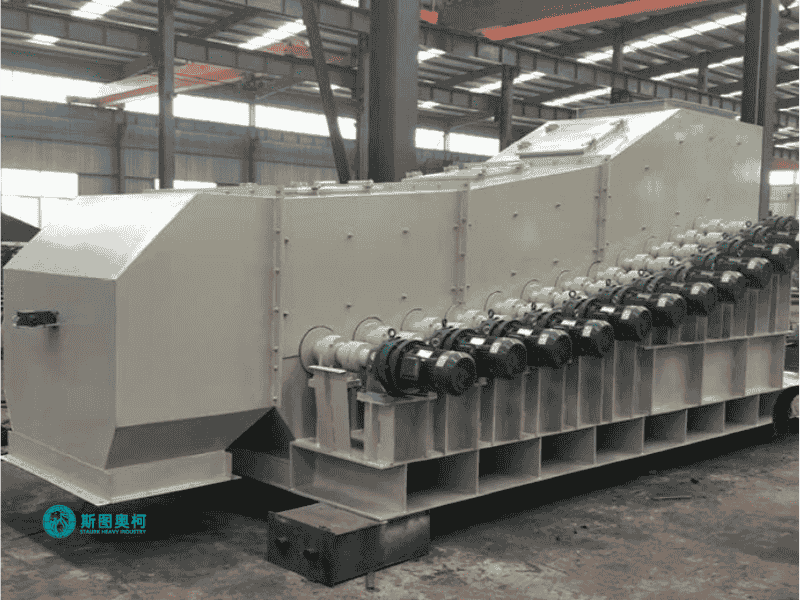

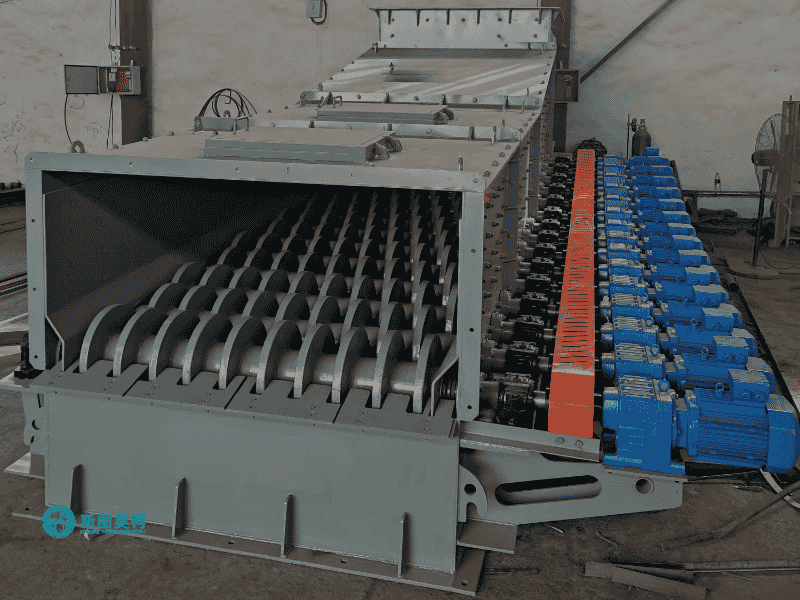

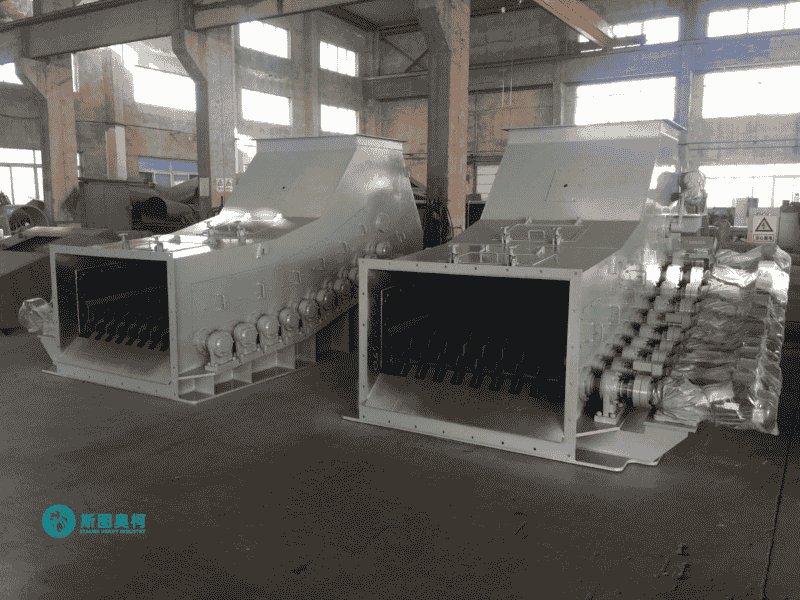

Roller Screen uses parallel rotating shafts to classify materials like aggregates, coal, and ores (5–300mm). With adjustable gaps (5–300mm) and a capacity of 30–1200 TPH, it efficiently separates particles into multiple grades (0–10mm, 10–30mm). Ideal for mining, recycling, and coal sorting, it offers clog-resistant operation and low noise, suited for dry/semi-wet materials.

Advantages

01.

High Efficiency

Processes 30-1200 TPH with precise material separation for maximum output.

02.

Adjustable Grading

Customized screen gaps (5-300 mm) for multi-size product requirements.

03.

Low Maintenance

Robust, clog-resistant design reduces downtime and operational costs.

04.

Quiet Operation

Smooth rotation ensures minimal noise in industrial environments.

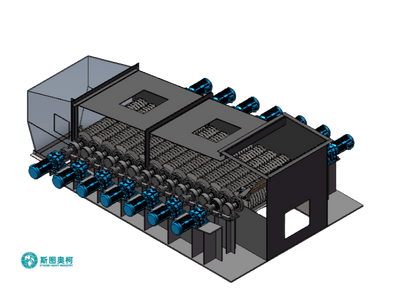

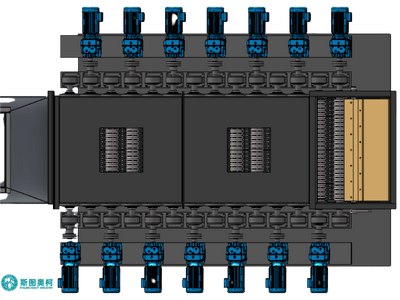

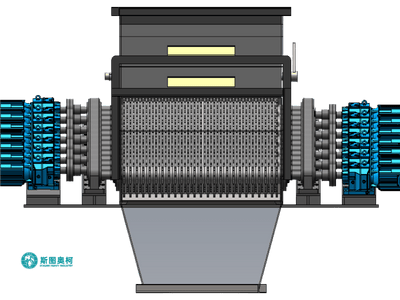

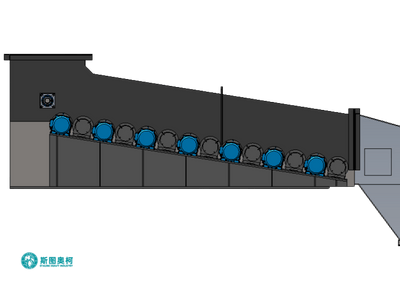

How Does A Roller Screen Work

1. Material Feeding & Transport: Raw materials enter the feed end and are conveyed forward by rotating parallel shafts equipped with discs or star-shaped rollers.

2. Size Separation Process: Smaller particles fall through adjustable gaps (5–300mm) between rollers, while oversized materials continue moving toward the discharge end.

3. Self-Cleaning Mechanism: The rotating motion prevents clogging by dislodging sticky particles, ensuring continuous operation with minimal downtime.

4. Output & Adaptability: Separated materials are discharged into graded fractions (0–10mm, 10–30mm), with capacity scalable from 30–1200 TPH for diverse applications like mining and recycling.

Applications

Models

Model | Capacity (TPH) | Max. Feed Size (mm) | Screen Gaps (mm) | No. of Rollers | Power (kW) | Dimensions (L×W×H, mm) | Weight (kg) | Applications |

RS-0630 | 30–80 | 150 | 5–40 (adjustable) | 6–8 | 5.5–7.5 | 6000×3000×2200 | 3200 | Coal, biomass |

RS-0840 | 50–100 | 200 | 5–50 | 8–10 | 7.5–11 | 8000×4000×2500 | 4500 | Aggregates, coal |

RS-1060 | 100–200 | 300 | 10–100 | 10–12 | 15–18.5 | 10000×6000×2800 | 6800 | Mining, recycling |

RS-1290 | 200–350 | 400 | 20–150 | 12–15 | 22–30 | 12000×9000×3200 | 9500 | Ore, construction waste |

RS-1512 | 350–500 | 500 | 30–200 | 15–18 | 37–45 | 15000×12000×3500 | 12000 | Heavy-duty mining |

RS-1815 | 500–800 | 600 | 50–250 | 18–22 | 55–75 | 18000×15000×4000 | 15000 | Iron ore, slag processing |

RS-2418 | 800–1200 | 800 | 80–300 | 24–28 | 90–110 | 24000×18000×4500 | 22000 | Large-scale quarry, bulk material |