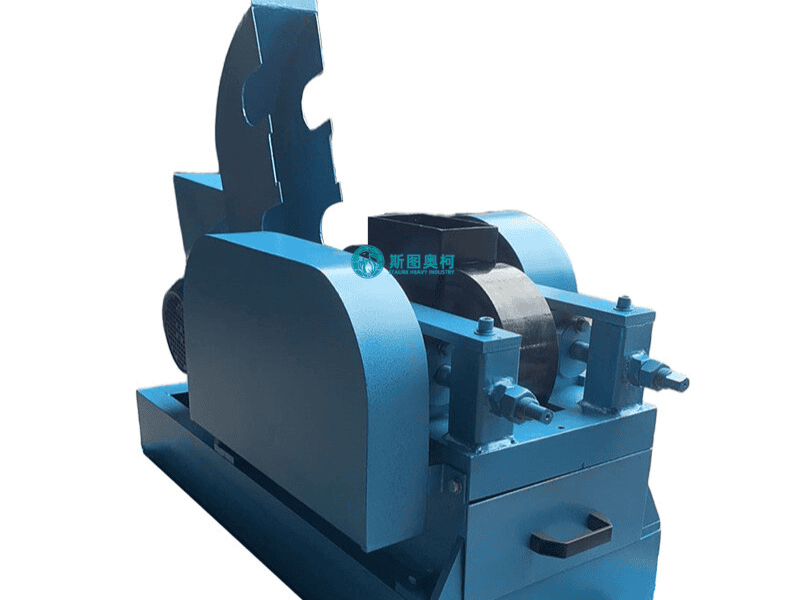

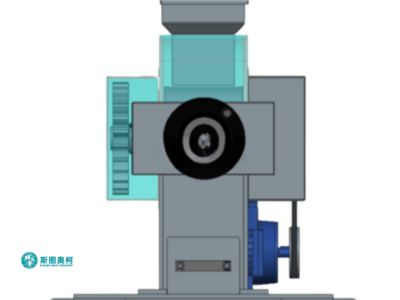

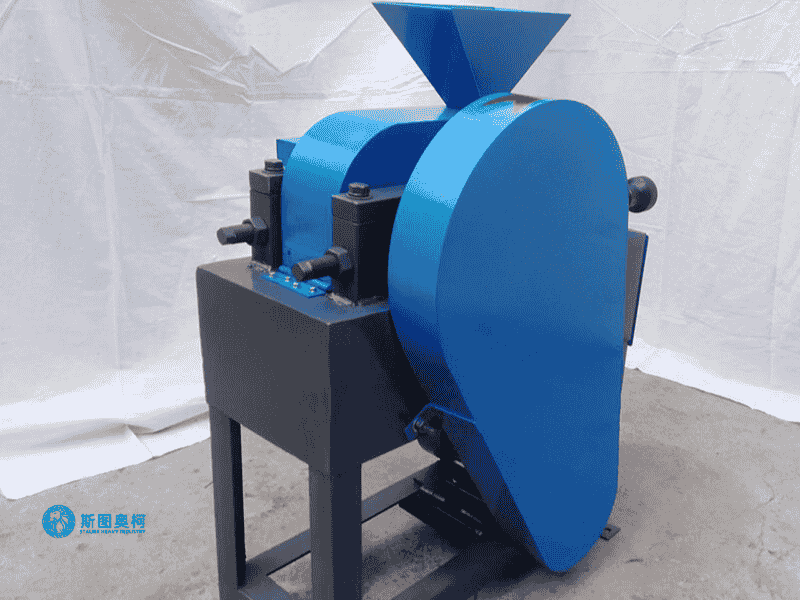

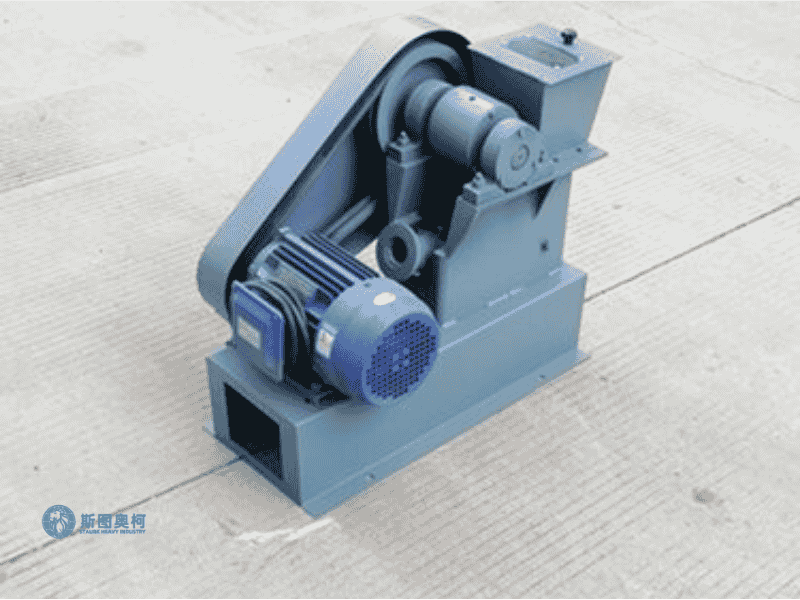

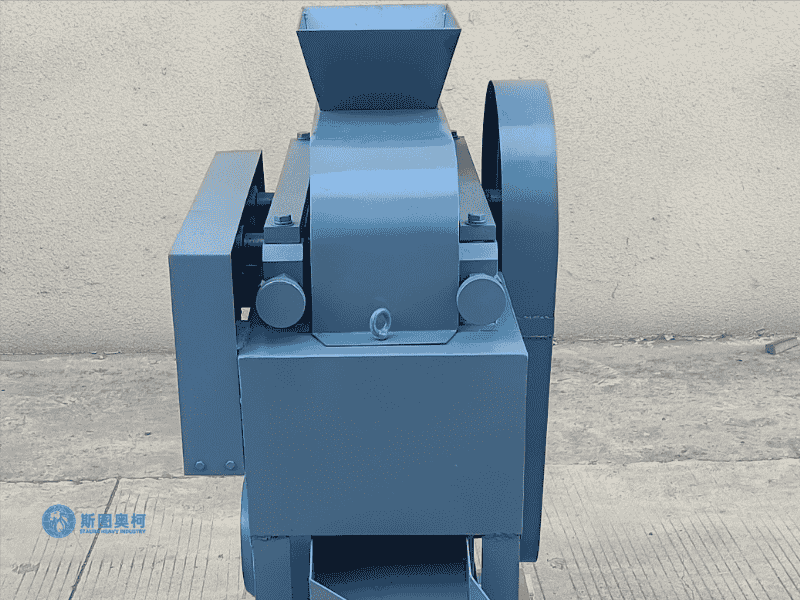

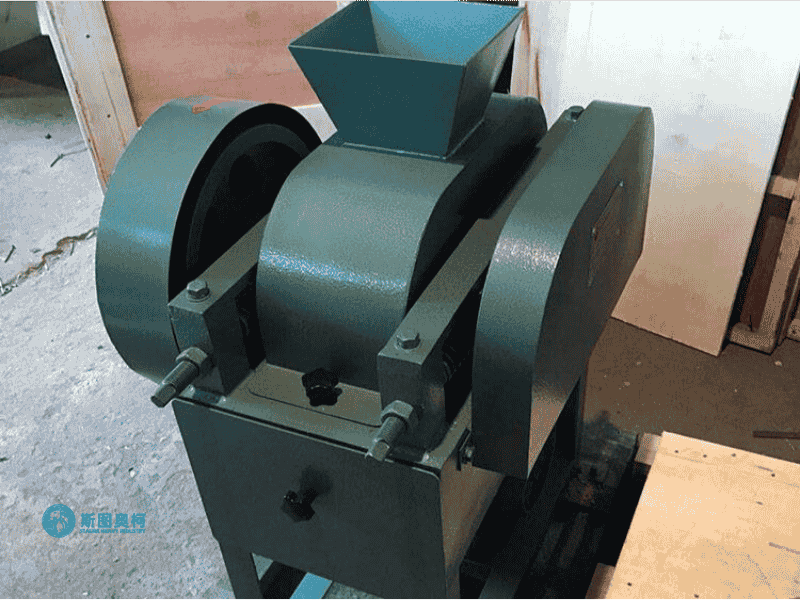

Laboratory Roller Crusher

Capacity: 10-200 KGPH

Feeding Size: ≤20 mm

Discharging Size: 0.1-5 mm

Handling Materials: Gold mine, iron mine, cement clinker, ceramics, etc.

Laboratory roller crusher processes brittle samples (≤20 mm) into 0.1–5 mm particles using counter-rotating rollers, achieving 10–200 kg/h throughput. Ideal for ore, coal, and ceramic preparation, it features adjustable gap control and overload protection. Avoid >7 Mohs materials.

Advantages

01.

Precise Size Control

Adjustable roller gaps (0.1–5mm) enable exact particle sizing, critical for sample reproducibility in assays and research studies.

02.

Low Fines Generation

Differential roller speeds (5–15% variance) minimize over-crushing, preserving +80% of material within target size ranges.

03.

Material Versatility

Handles coal, ores, and ceramics (≤7 Mohs) with interchangeable smooth/toothed rollers for different textures.

04.

Compact Safety

Benchtop design (20–50 kg) features auto-stop overload protection and dust containment for lab environments.

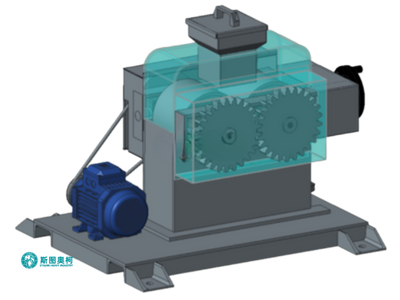

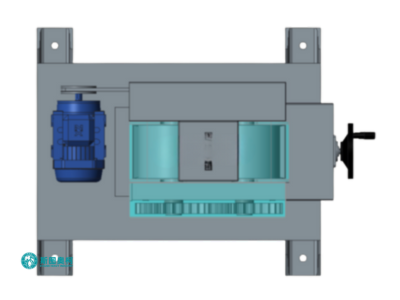

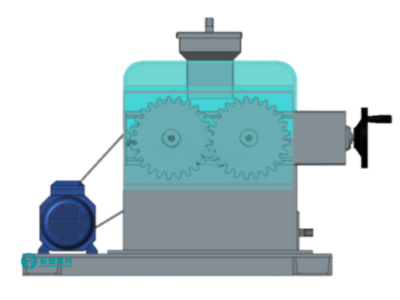

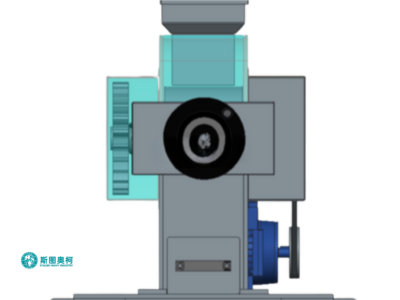

How Does A Laboratory Roller Crusher Work

1. Material Feeding: Samples (≤20 mm) are fed between two parallel rollers, one fixed and one movable, via a vibration-free hopper to ensure even distribution.

2. Compression & Shearing: Counter-rotating rollers (50–200 RPM) with adjustable gap (0.1–5 mm) crush particles through combined compressive and shear forces.

3. Particle Reduction: Differential roller speeds (5–15% variance) enhance grinding efficiency while minimizing fines, producing uniform 0.1–5 mm output.

4. Product Discharge: Crushed material exits freely; dust is contained via sealed chambers or extracted through vacuum ports for clean operation.

Applications

Models

Model | Feed Size (mm) | Discharge Size (mm) | Capacity (kg/h) | Power (kW) | Weight (kg) | Dimensions (L x W x H, mm) | Application |

RC-50 | 10 | 1-5 | 50-100 | 0.75 | 80 | 600 x 400 x 500 | Small-scale laboratory crushing |

RC-100 | 20 | 2-10 | 100-200 | 1.5 | 120 | 800 x 500 x 600 | Medium-scale sample preparation |

RC-150 | 30 | 5-15 | 200-400 | 2.2 | 150 | 1,000 x 600 x 700 | Large-scale laboratory crushing |

RC-200 | 40 | 10-20 | 400-600 | 3.0 | 200 | 1,200 x 700 x 800 | Industrial research and testing |

RC-250 | 50 | 15-25 | 600-800 | 4.0 | 250 | 1,500 x 800 x 900 | Heavy-duty laboratory crushing |