Laboratory Ring Mill

Capacity: 10–500g/time

Feeding Size: ≤5 mm

Discharging Size: 10–150μm

Handling Materials: Gold ore, iron ore, ceramics, etc.

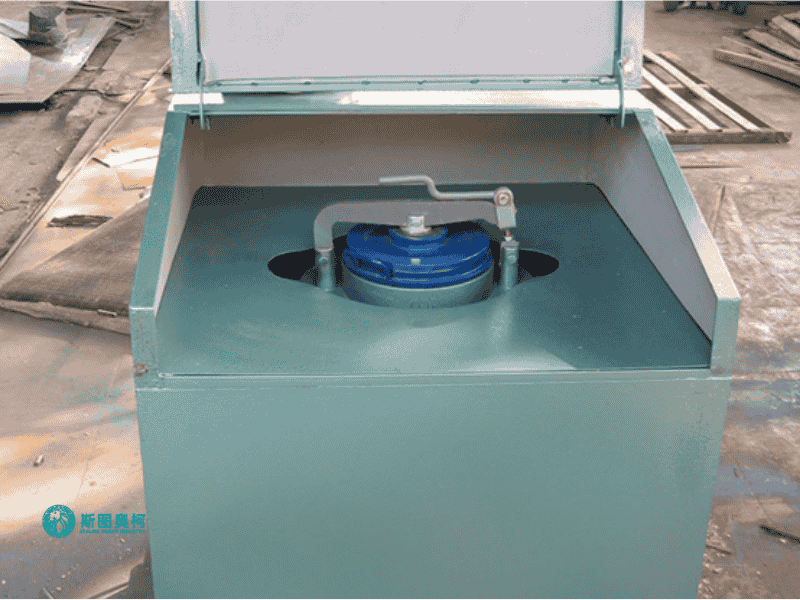

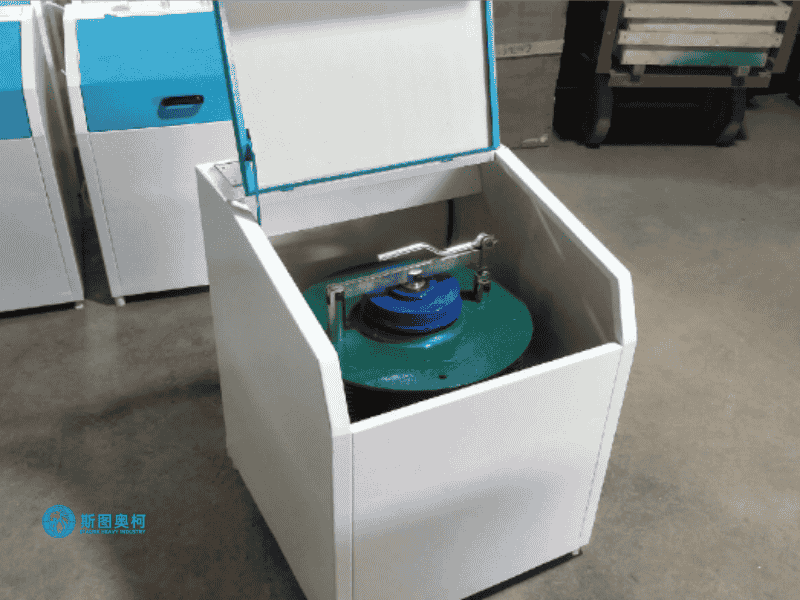

A laboratory ring mill is a robust grinding machine used to pulverize hard, brittle materials into fine powders. It features a rotating ring and stationary puck that crush samples through high-pressure impact. Ideal for minerals, ceramics, and chemicals, it ensures uniform particle size for accurate analysis. Its durable construction and efficient operation make it essential in sample preparation for laboratories.

Advantages

01.

Efficient Grinding

Quickly pulverizes hard, brittle materials into fine powders, reducing processing time and improving workflow efficiency in sample preparation.

02.

Uniform Particle Size

Ensures consistent, homogeneous particle distribution, critical for accurate analytical results in lab testing and research.

03.

Durable Construction

Built with robust materials to withstand heavy use, offering long-term reliability and minimal maintenance requirements.

04.

Versatile Applications

Suitable for various materials like minerals, ceramics, and chemicals, making it adaptable for different lab needs.

How Does A Laboratory Ring Mill Work

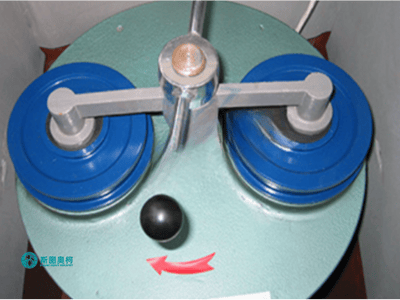

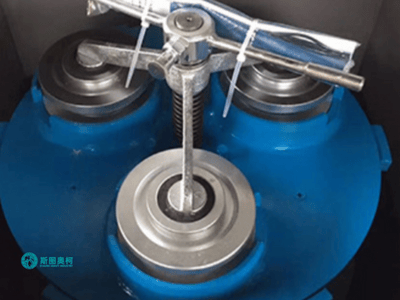

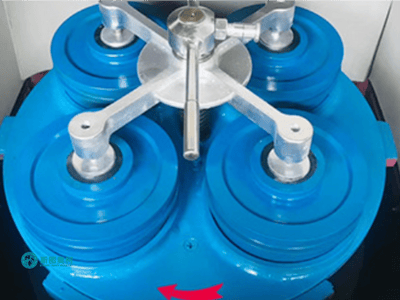

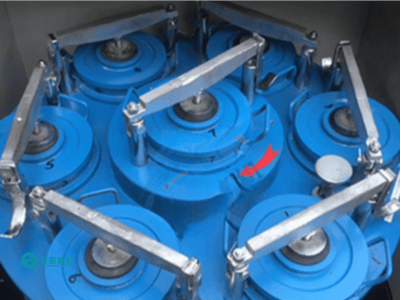

1. Crushing Mechanism: The ring mill uses a rotating hardened steel ring and a stationary puck or plate. The sample is placed between them and crushed through high-pressure impact and friction.

2. Grinding Action: As the motor spins the ring at high speed, the sample is repeatedly compressed and sheared, breaking it down into fine particles.

3. Particle Size Control: Adjustable pressure and grinding time allow precise control over fineness, ensuring consistent particle size for accurate lab analysis.

4. Containment & Safety: A sealed chamber prevents sample loss and contamination while reducing dust exposure, enhancing operator safety and sample integrity.

Applications

Models

Model | Grinding Capacity (g) | Feed Size (mm) | Final Fineness (µm) | Power (kW) | Weight (kg) | Dimensions (L x W x H, mm) | Application |

RM-100 | 100 | 10 | 50-100 | 1.1 | 50 | 500 x 400 x 600 | Small-scale laboratory grinding |

RM-200 | 200 | 15 | 20-50 | 2.2 | 80 | 600 x 500 x 700 | Medium-scale sample preparation |

RM-300 | 300 | 20 | 10-20 | 3.0 | 120 | 700 x 600 x 800 | Large-scale laboratory grinding |

RM-400 | 400 | 25 | 5-10 | 4.0 | 150 | 800 x 700 x 900 | Industrial research and testing |

RM-500 | 500 | 30 | 1-5 | 5.5 | 200 | 900 x 800 x 1,000 | Heavy-duty laboratory grinding |