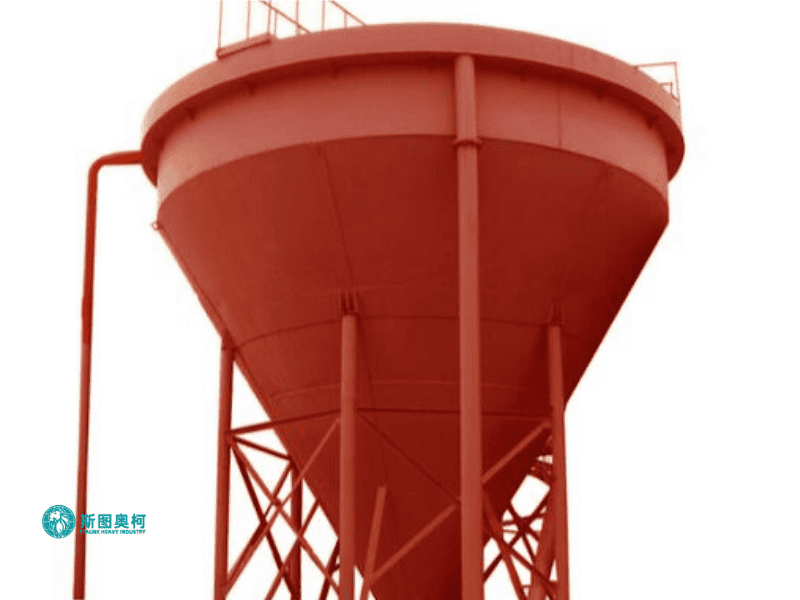

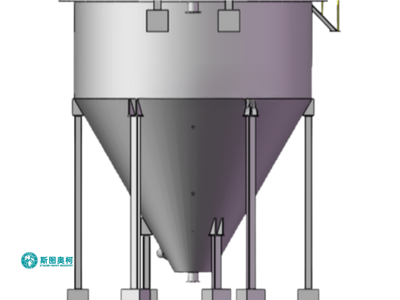

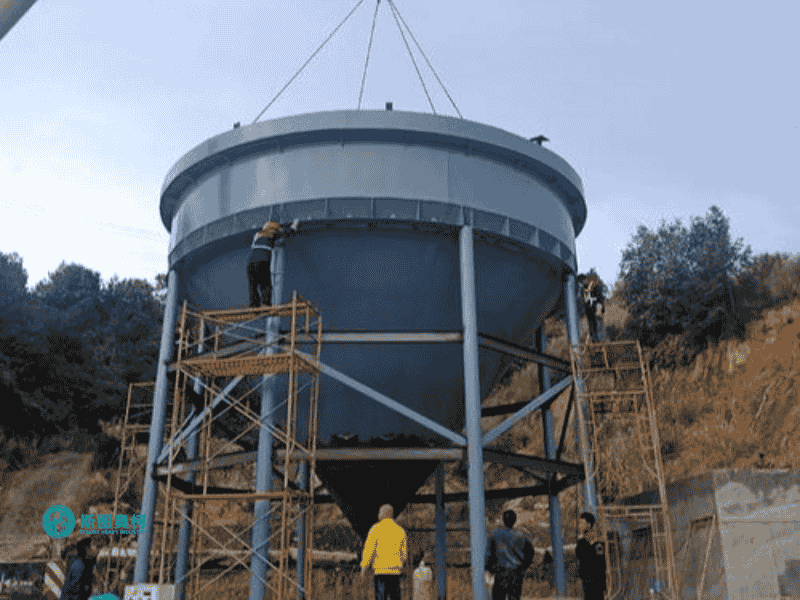

Deep Cone Thickener

Capacity: 5-2600 m³/h

Feeding Size: 0–300 μm

Discharging Size: 40–75% solids

Handling Materials: Tailings dewatering, concentrate concentration, sludge dewatering, etc

Deep cone thickener concentrates slurries (0–300μm) to 40–75% solids via gravity and flocculation, handling 5–500m³/h. Its steep cone design accelerates settling, producing clear overflow (<500ppm SS) and dense underflow. Ideal for tailings dewatering but requires pre-screening of >0.5mm particles.

Advantages

01.

High Density Underflow

Achieves 60–75% solids in underflow via steep cone geometry and optimized floculation, reducing downstream drying costs by 30–50%.

02.

Clear Overflow

Produces effluent with <500ppm suspended solids (SS), meeting reuse/discharge standards without additional filtration.

03.

Energy Efficient

Consumes only 0.5kWh/t solids, 60% less than centrifuges, thanks to gravity-driven settling.

04.

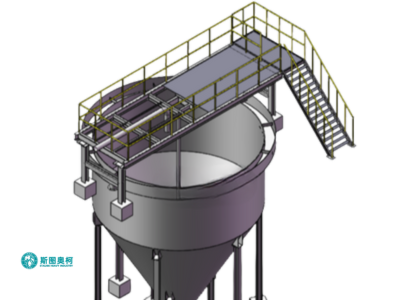

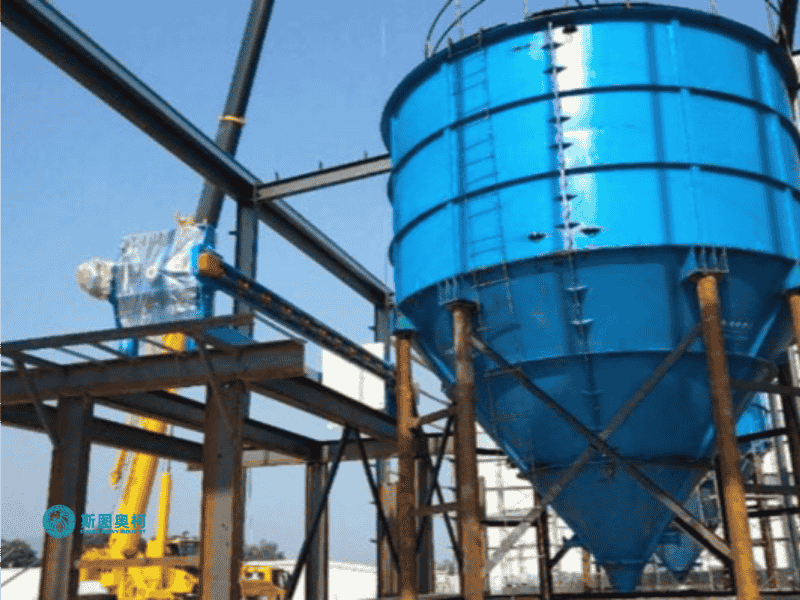

Compact Footprint

Deep cone design reduces diameter by 40% versus conventional thickeners for equivalent capacity (5–500 m³/h).

How Does A Deep Cone Thickener Work

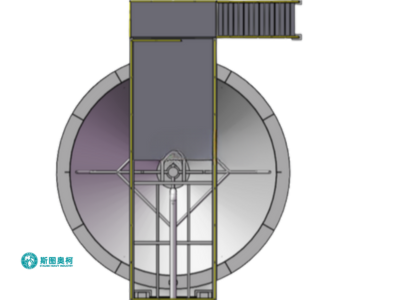

1. Floculated Feed Entry: Dilute slurry (10–30% solids) is mixed with floculant (5–50 g/t) and injected into the thickener’s center well, where polymers bind fine particles into aggregates.

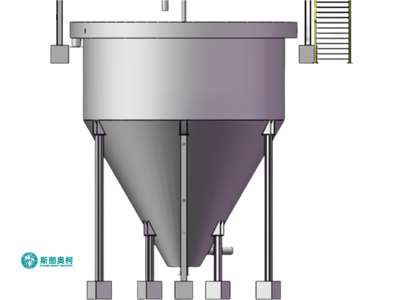

2. Gravity Settling: Dense flocs sink rapidly through the steep cone (55–60° slope), while clarified water rises to overflow launders (<500 ppm SS).

3. Compression Zone: Thickened solids are compressed by the cone’s narrowing geometry and rotating rakes (0.1–1 RPM), reaching 60–75% density.

4. Controlled Discharge: Underflow pumps extract concentrated slurry, with bed-level sensors automatically adjusting discharge rates to maintain optimal residence time.

Applications

Models

Model | Diameter of Thickener (mm) | Depth of Thickener (mm) | Area of Sediment (m²) | Capacity (m³/h) |

GSNG-3 | 3000 | 4400 | 21 | 60–70 |

GSNG-6 | 6000 | 8800 | 85 | 210–260 |

GSNG-9 | 9000 | 13500 | 310 | 570–700 |

GSNG-12 | 12000 | 17500 | 510 | 800–1200 |

GSNG-15 | 15000 | 19000 | 1200 | 1000–1500 |

GSNG-18 | 18000 | 22000 | 2000 | 1400–2100 |

GSNG-20 | 20000 | 22800 | 2700 | 2100–2600 |