Background

A Ghanaian client, Mr. Walido, he owns a mining area with high-quality quartz sand and abundant reserves, but the extracted raw sand contains a large amount of clay and moisture. The traditional natural drying method is inefficient and limited by the rainy season, resulting in yellowing of the product and high moisture content that cannot meet the quality requirements of international buyers. Therefore, they urgently need an efficient sand washing and dewatering line to remove impurities, accurately grade and significantly reduce moisture, in order to elevate the product to a high standard that can be used for building and industrial grade glass.

Solutions

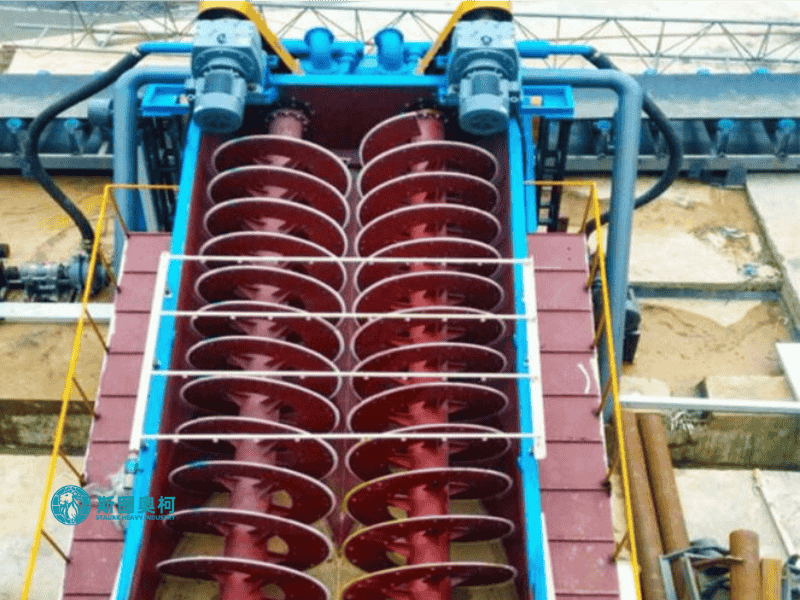

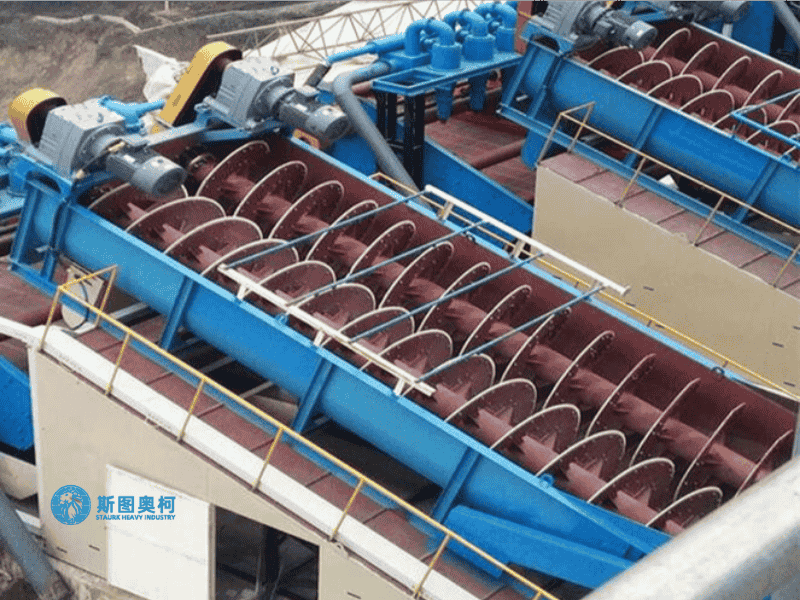

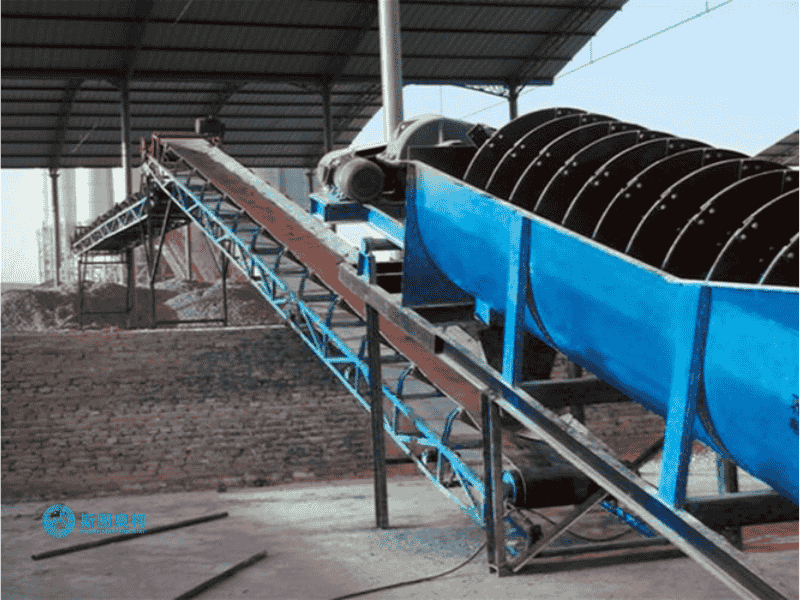

For the washing and dewatering demand of 200 tons of quartz sand per hour, we provide a complete solution: the raw materials are transported from the hopper to the screw washer through a belt conveyor. Under the strong friction of the screw blades and water flow flushing, the sand particles and clay impurities are completely separated. The washed sand enters the high-frequency dewatering screen and undergoes severe vibration dewatering. At the same time, the wastewater from the screw washer enters the cyclone group and fine sand recovery system for fine sand recovery, in order to minimize the loss of fine sand and ultimately produce low moisture finished sand.

Case Photos

Feedback

Mr. Walido's feedback on quartz sand washing production line: we are very satisfied with this sand washing and dewatering line. It not only fully meets the core requirements of quartz sand washing and deep dewatering, but also produces clean and dry sand with stable quality far exceeding expectations. Its efficient and energy-saving design greatly reduces operating costs. The excellent reliability of the sturdy and durable equipment in harsh local environments gives us confidence in continuing to expand our market share.