Background

Mr. Mike is a Polish client, he wants a cone crusher, its capacity is 200 tons per hour. The material is basalt, the maximum size is 180mm, the granularity required for discharging is 20-30mm. Because the hardness of customers' materials is relatively high and the output requirements are high, we recommend XHP300 hydraulic cone crusher.

Solutions

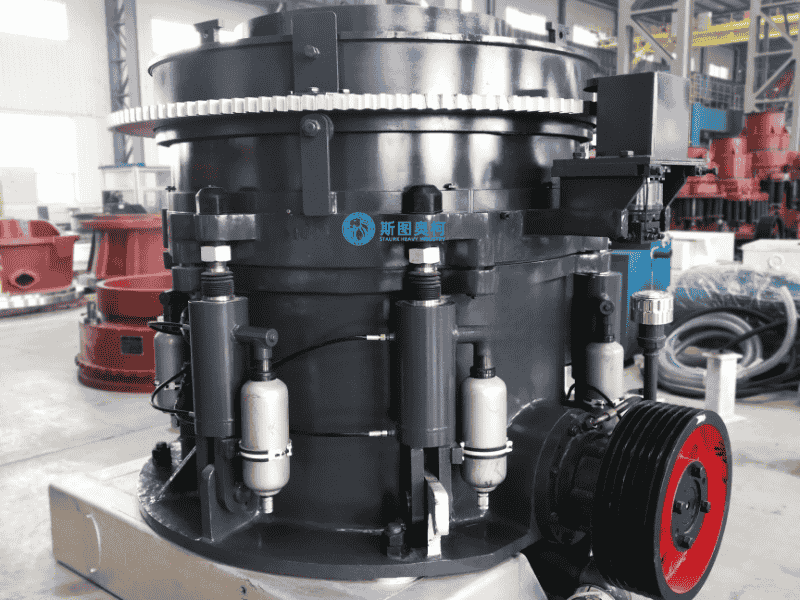

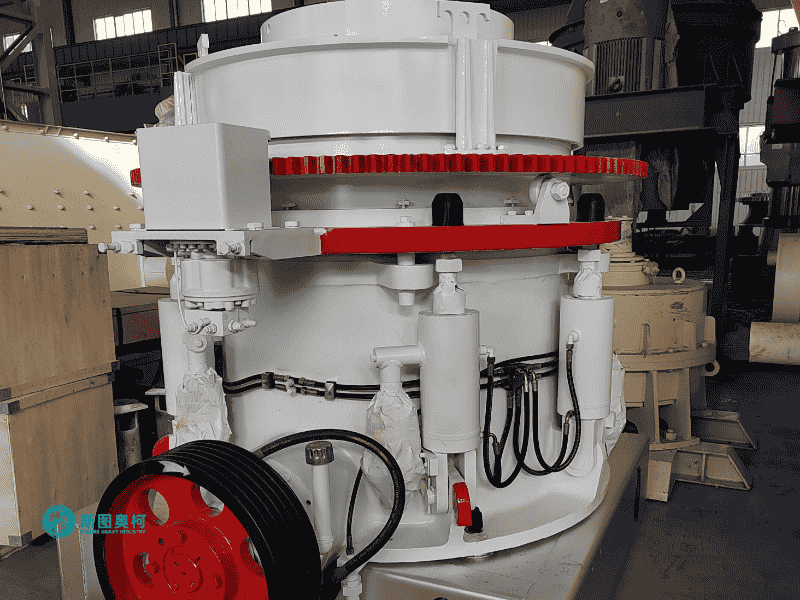

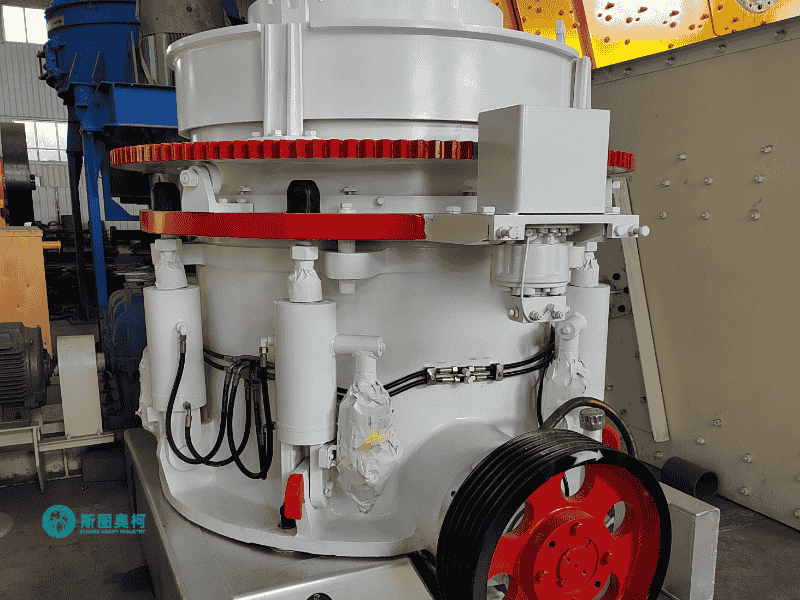

The XHP300 hydraulic cone crusher is a high-performance crushing machine designed for secondary and tertiary crushing of medium to high-hardness materials (Mohs hardness 5-16), such as granite, basalt, iron ore, gold ore, and copper ore. It features an advanced hydraulic system for automatic discharge adjustment (10-50mm range) and tramp iron protection, ensuring optimal efficiency. Powered by a 160kW (220HP) motor, the crusher utilizes a laminated crushing principle to produce well-shaped aggregates (low flakiness content) while reducing energy consumption by 15-20% compared to traditional spring cone crushers. Key components include a high-manganese steel crushing chamber, independent hydraulic lubrication station, and PLC-based intelligent control system for real-time monitoring of bearing temperature, oil pressure, and operational parameters.

Case Photos

Feedback

Mr. Mike's feedback on cone crusher: Save cable and transformer investment, reduce expenses, and complete parking-operation conversion in 30 minutes without concrete foundation.