Choosing the right crusher depends primarily on the material characteristics. The hardness, abrasiveness, moisture content, and feed size of the raw material dictate the crusher type. For soft to medium-hard rocks like limestone, impact crushers or hammer mills are ideal due to their high reduction ratios. For extremely hard materials like granite or iron ore, jaw crushers (primary) followed by cone crushers (secondary) are more suitable. Sticky or wet materials may require specialized crushers like roll crushers to prevent clogging.

Production requirements and operational conditions play a crucial role. The required output size and capacity determine whether a single-stage or multi-stage crushing process is needed. Mobile crushers are preferred for temporary sites or projects requiring frequent relocation, while stationary crushers suit large-scale, long-term operations. Energy efficiency and automation features (e.g., hydraulic adjustment, real-time monitoring) should also be considered to optimize productivity and reduce downtime.

Maintenance and operational costs are key decision factors. Some crushers, like jaw and cone types, have higher upfront costs but lower wear-part replacement frequency, making them cost-effective for abrasive materials. Others, like impact crushers, offer lower initial investment but may incur higher maintenance expenses due to faster wear in hard-rock applications. Additionally, ease of access for liner changes and availability of spare parts influence long-term operational efficiency.

Environmental and site-specific constraints must be addressed. Noise, dust emissions, and energy consumption should comply with local regulations—enclosed designs and dust suppression systems may be necessary. Space limitations, power supply availability, and climate conditions (e.g., extreme temperatures) also affect crusher selection. Consulting manufacturers for tailored solutions and reviewing case studies from similar operations can ensure optimal performance and cost-efficiency.

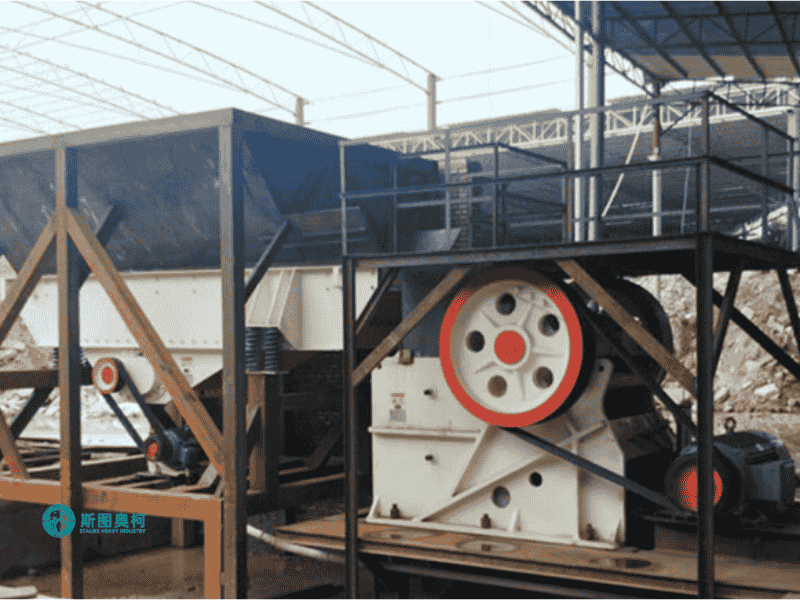

In summary, Saturk Machinery recommends that you choose a suitable crusher based on different materials, production volumes, feed particle sizes, and discharge requirements. You can also consult us and we will provide you with a detailed plan.