Selecting the right vibrating screen starts with analyzing material characteristics and screening objectives.

The particle size distribution, moisture content, and abrasiveness of the feed material determine whether a linear, circular, or elliptical motion screen is most suitable. For dry, free-flowing materials, high-frequency screens may be optimal, while wet or sticky materials often require washing screens or specialized deck surfaces like polyurethane or rubber mats. The desired separation accuracy and efficiency will influence decisions about deck configuration and screen aperture design.

Production requirements and operational conditions are critical factors in selection.

Required throughput capacity dictates whether single- or multi-deck screens are necessary, while available headroom may influence the choice between horizontal and inclined designs. The vibration intensity and frequency must be matched to both material characteristics and structural constraints of the installation site. Energy efficiency considerations become particularly important for continuous, high-volume operations where even small power savings can significantly impact operating costs.

Durability and maintenance considerations significantly affect long-term performance.

Screens with easily replaceable components and wear-resistant surfaces reduce downtime and maintenance costs. The choice between bearing-based and rubber suspension systems impacts both vibration transmission and component lifespan. Environmental factors like temperature extremes, dust generation potential, and corrosion risks should inform material selections for screens operating in challenging conditions.

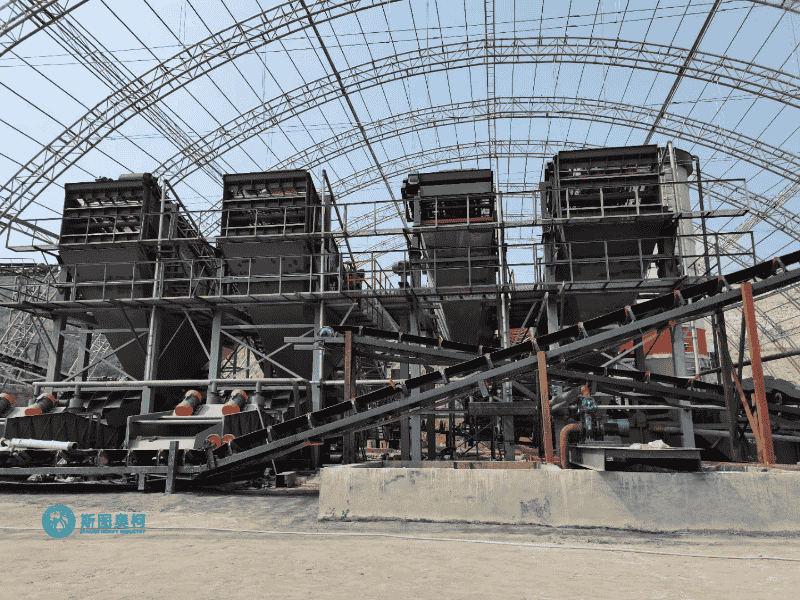

Integration with overall system requirements completes the selection process.

The screen must properly interface with upstream and downstream equipment in terms of both physical dimensions and process flow characteristics. Special features like dust enclosures, noise reduction housings, or explosion-proof designs may be necessary depending on plant specifications. Future process modifications or capacity expansions should be considered during initial selection to ensure flexibility. Manufacturer expertise in similar applications can provide valuable guidance for optimizing both performance and cost-effectiveness.

So far, we have a certain understanding of vibrating screens and need to choose them based on the particle size distribution, moisture content, viscosity, and screening accuracy requirements of the material. If you need to know more, please consult Staurk Machinery.