Background

An Australian client, Mr. Tomi, He consulted our company for 150tph basalt sand washing and dewatering production line. He has his own crushing line and sand-making line, and the material is basalt sand. Because the mud content in basalt sand is relatively large, it needs to be cleaned to get clean sand with low water content.

Solutions

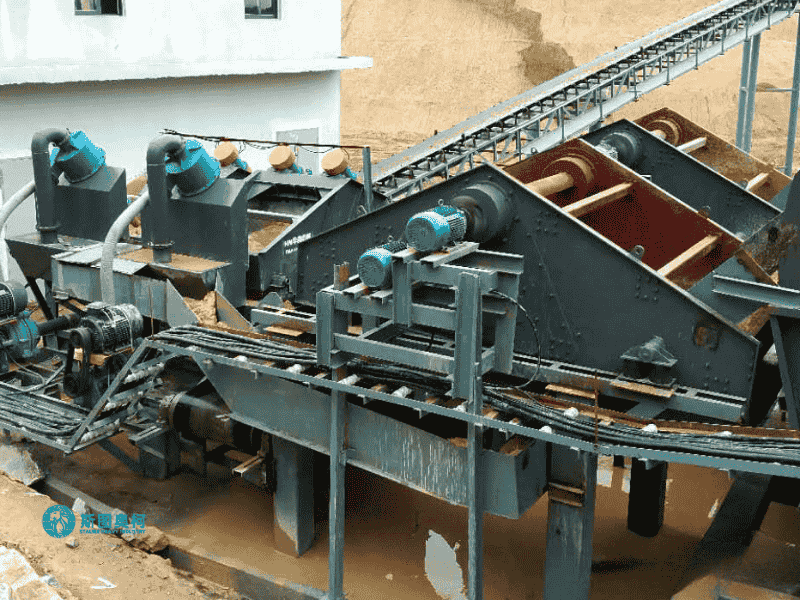

This 150tph basalt sand washing and dewatering production line processes raw materials through a sequential system starting with a 1200mm wide heavy-duty belt conveyor operating at 1.25m/s speed to feed material into a Φ1500×4500mm trommel screen with 5mm aperture polyurethane panels that removes +5mm oversize particles, followed by a 2620×2850mm bucket wheel sand washer featuring 8-10rpm rotating speed and 50-80m³/h water consumption that thoroughly cleanses 0-5mm sand through mechanical scrubbing, then processes the washed sand through a 1800×4800mm dewatering screen with 0.3mm sieve mesh and 950rpm vibration frequency to reduce moisture content below 15%, ultimately producing premium construction sand with uniform 0-5mm particle size distribution, less than 3% mud content and optimal cleanliness meeting ASTM C33 standards, while the entire system operates at 55kw total power consumption with 98% continuous operation reliability and automatic controls for stable processing of 150t/h basalt feed material.

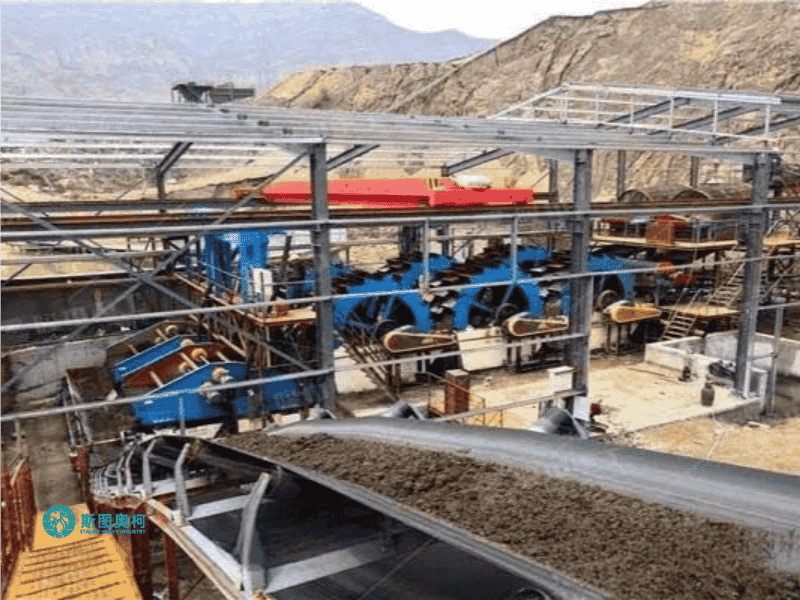

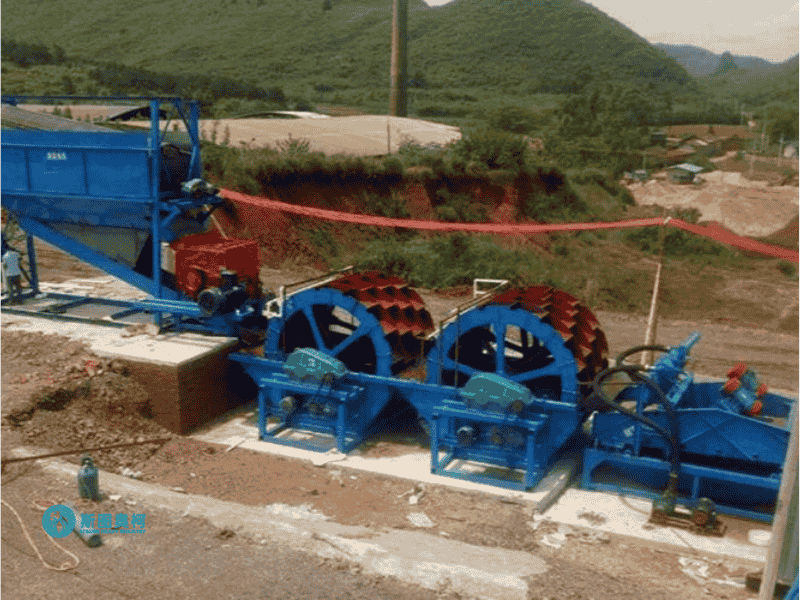

Case Photos

Feedback

Mr. Tomi's feedback on 150tph basalt sand washing and dewatering production line: The processed basalt sand emerges with significantly improved quality after undergoing thorough treatment through the integrated washing system, where the trommel screen effectively removes oversized particles and debris, the bucket wheel washer vigorously scrubs away clay and impurities while preserving the natural grain structure, and the dewatering screen substantially reduces moisture content to yield clean, uniformly graded sand with optimal workability, resulting in a premium construction material that exhibits enhanced binding properties, consistent particle distribution, and superior cleanliness ready for immediate use in high-performance concrete applications or other demanding construction purposes.