Overview

Stone Crushing Plant Introduction

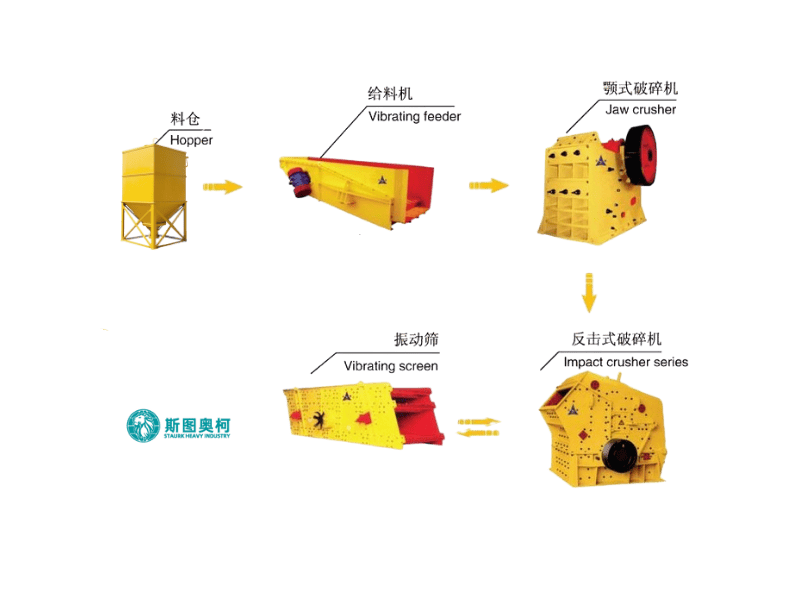

This 100-ton-per-hour stone crushing plant is designed for efficient processing of medium-hard materials like limestone, granite, and basalt. The line features a two-stage crushing system: a jaw crusher for primary coarse crushing (reducing large rocks to ~100–200mm) and an impact crusher for secondary fine crushing (producing well-shaped aggregates of 0–40mm). Raw material is evenly fed by a vibrating feeder to ensure stable operation, while a vibrating screen classifies the final output into multiple specifications (0–5mm, 5–20mm). With its compact layout, low maintenance requirements, and high automation, this crushing line delivers durable, high-quality aggregates for construction, road building, and concrete production while minimizing dust and noise emissions.

Stone Crushing Plant Application

The stone crushing line is widely used in multiple industries for processing various raw materials into desired aggregate sizes. Its primary applications include: construction (producing concrete aggregates, cement raw materials, and building stones), road and railway infrastructure (creating base layers, asphalt aggregates, and ballast stones), and mining operations (preparing ores for further processing). Additionally, the crushed stone is essential for landscaping projects, drainage systems, and precast concrete products. With adjustable output sizes (from coarse gravel to fine sand), modern crushing lines can meet diverse industrial requirements while maintaining high efficiency, environmental compliance, and cost-effectiveness.

Stone Crushing Plant Working principle

1.Vibrating feeder is the first step of crushing production line, which is responsible for sending limestone in raw material bin into crushing equipment evenly and continuously. This equipment has simple structure and stable operation, which can effectively control the flow of materials and provide stable input for the subsequent crushing process.

2.Jaw crusher is mainly used for coarse crushing of limestone. Due to the low hardness of limestone, jaw crusher can easily crush large-size limestone with its reasonable inlet design and strong crushing ability. In addition, the jaw crusher has uniform crushing particle size, which is beneficial to the smooth progress of the subsequent crushing process.

3.Impact crusher is used for medium and fine crushing of limestone. Impact crusher has the advantages of high crushing efficiency, low wear and uniform particle size of products, which is suitable for further refining the crushed materials of jaw crusher.

4.The circular vibrating screen is used to screen the crushed limestone, and the product materials are screened into various specifications. By setting up multi-layer screens, the vibrating screen can complete accurate particle size classification and ensure the quality of the final product.

5.Belt conveyor is used to transport the crushed and screened materials to the next working procedure or product area. This kind of equipment is stable in operation and simple in maintenance, and it is an indispensable conveying equipment in limestone crushing production line.

Stone Crushing Plant Features

1.Two-Stage Crushing Process: The line features primary crushing with a jaw crusher (for coarse crushing) and secondary crushing with an impact crusher (for finer shaping), ensuring efficient size reduction and good particle shape.

2.Continuous Flow Design: Equipped with a vibrating feeder for steady material supply, the process ensures smooth operation with minimal bottlenecks between the jaw crusher, impact crusher, and vibrating screen.

3.Flexible Screening & Gradation: The final vibrating screen classifies the output into desired sizes, allowing adjustable product specifications to meet diverse requirements.

4.Compact & Efficient Layout: The sequential arrangement (feeder → jaw crusher → impact crusher → screen) optimizes space utilization and reduces material transfer distances, enhancing overall productivity.