Overview

Sand Washing Plant Introduction

The 100 t/h sand washing production line processes raw sand (0-30mm) by first removing oversized debris through screening, then conveying material via heavy-duty belt conveyor to the wheel sand washer where twin impellers scrub and remove 95%+ impurities using 3-5m³ water per ton. The system efficiently recovers 85-90% of fine sand particles (0.075-0.6mm) through hydrocyclone separation and dewatering while recycling 80% of process water via sedimentation tanks. The final washed sand (0-5mm with ≤3% silt content) is stored in the product hopper. This compact system (15×30m footprint) features wear-resistant components, PLC automation for precise operation control (25-35kW power consumption), and is ideal for producing high-quality construction aggregates, processing mineral sands (quartz/silica), and treating recycled materials or river dredgings while minimizing water usage and environmental impact through its closed-loop water recycling design.

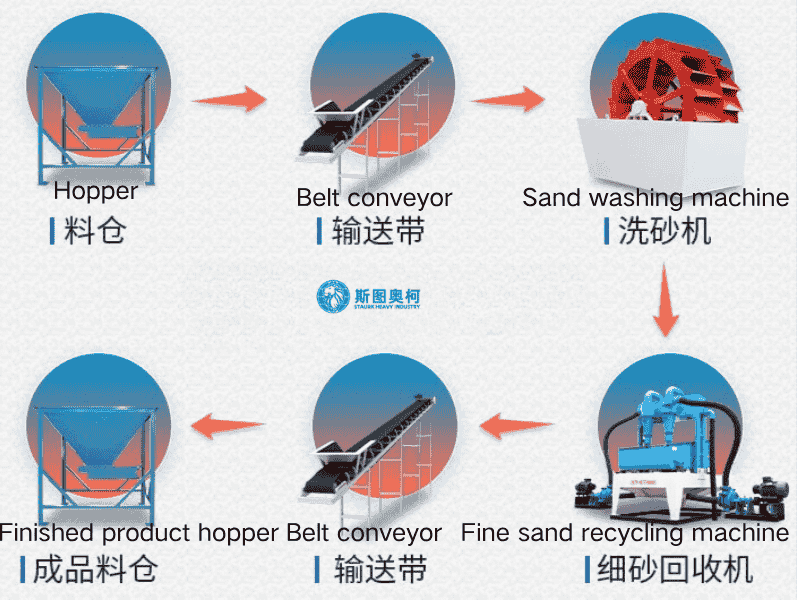

Sand Washing Plant Working Principle

1.Feeding Stage (Hopper)

The process begins as raw sand (0-30mm) with impurities is fed into the hopper. An optional grizzly screen removes oversized debris (>50mm) while allowing properly sized material to pass through to the next stage. The hopper ensures a steady, controlled feed rate of 100 tons per hour into the system.

2.Material Transportation (Belt Conveyor)

A heavy-duty belt conveyor (800mm width) transports the material at 1.2m/s speed with a 12° incline. This efficient transfer method maintains consistent feed to the washing unit while handling the full production capacity without clogging or spillage.

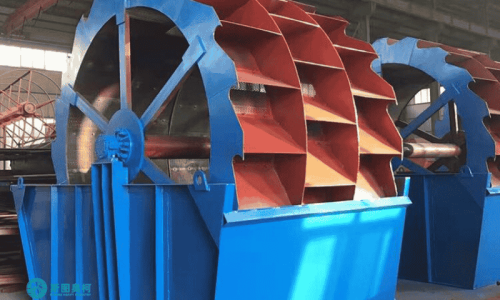

3.Primary Washing (Wheel Sand Washer)

The wheel sand washer's twin-impeller design creates intense agitation in the water bath, effectively scrubbing and separating clay and organic impurities from sand particles. This stage consumes 3-5m³ of water per ton of material processed and removes over 95% of contaminants through mechanical washing and buoyancy separation.

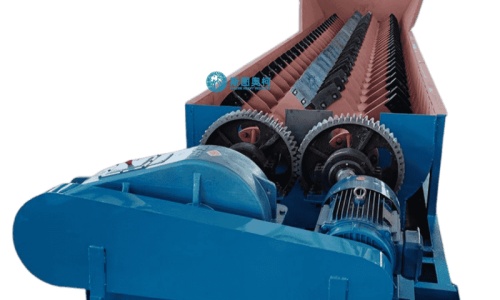

4.Fine Sand Recovery

The fine sand recovery unit combines hydrocyclone separation with dewatering screens to capture 85-90% of valuable fine particles (0.075-0.6mm) that would otherwise be lost in the wastewater. This critical stage significantly improves overall sand yield and product quality.

5.Final Product Handling

Clean, graded sand (0-5mm with ≤3% silt content) is discharged to the product hopper, which features level sensors for automated loading operations. The entire process achieves 80% water recycling through an integrated sedimentation system, making it both efficient and environmentally friendly.

Sand Washing Plant Application

This 100t/h sand washing production line is widely used in construction aggregate production for high-quality concrete/asphalt sand (silt content ≤3%), mineral processing (quartz/silica sand purification with SiO₂ >98%), recycled building material treatment (converting demolition waste into reusable aggregates), and river dredging operations (cleaning natural sand deposits). It efficiently serves medium-sized mining operations, ready-mix concrete plants, and environmental remediation projects by delivering consistently clean, graded sand (0-5mm) while recovering 85-90% of fine particles (0.075-0.6mm) and recycling 80% process water, making it particularly valuable in water-sensitive regions and urban construction projects requiring sustainable material processing solutions.

Sand Washing Plant Features

1.High-Efficiency Cleaning Performance

The production line achieves superior cleaning results with 95%+ impurity removal rate through its advanced wheel sand washer design. The twin-impeller system creates optimal turbulence for thorough scrubbing while maintaining low water consumption (3-5m³ per ton).

2.Comprehensive Fine Sand Recovery

The integrated fine sand recovery unit effectively captures 85-90% of valuable 0.075-0.6mm particles that would otherwise be lost, significantly improving overall yield and reducing material waste in the washing process.

3.Water Conservation System

Featuring an 80% water recycling rate through sedimentation tanks, the line demonstrates exceptional environmental performance. The closed-loop water management minimizes freshwater requirements and complies with strict environmental regulations.

4.Automated Operation & Control

PLC-based automation ensures precise control over all parameters including feed rate, water volume, and processing intensity. The system includes product hopper level sensors for automated loading and continuous operation monitoring.

5.Durable Construction & Low Maintenance

Built with wear-resistant alloys at all critical contact points, the equipment offers extended service life even when processing abrasive materials. The robust design requires minimal maintenance while delivering reliable performance.

6.Compact & Flexible Layout

The complete system fits within a 15×30m footprint, offering space efficiency without compromising capacity. Modular design allows for customization and adaptation to various site conditions and production requirements.

7.Versatile Material Processing

Capable of handling diverse feed materials including natural sand, crushed aggregates, and recycled demolition waste, the line consistently produces high-quality sand meeting construction specifications (0-5mm with ≤3% silt content).