Overview

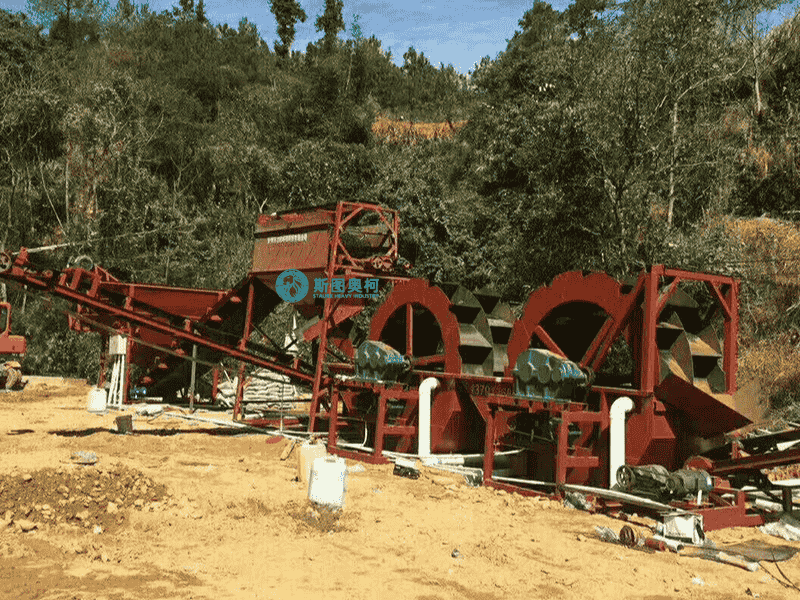

Sand Washing Plant Introduction

This 200-ton-per-hour river sand washing production line efficiently processes raw sand through a streamlined system consisting of a feed belt conveyor that transports material to a high-capacity bucket wheel sand washer, where thorough scrubbing and cleaning remove impurities, followed by a discharge belt conveyor that delivers the washed sand to the next stage. The compact yet robust setup ensures consistent output of high-quality construction-grade sand while maintaining low water consumption and reliable operation. The bucket wheel washer's gentle tumbling action effectively separates clay and organic matter without excessive wear on sand particles, making this continuous washing line ideal for producing clean, uniformly graded sand from river deposits.

Sand Washing Plant Application

This 200-ton-per-hour river sand washing production line is widely used in construction, concrete production, and infrastructure projects to process raw river sand into high-quality construction-grade material. It serves sand and gravel plants, precast concrete factories, and ready-mix concrete facilities by effectively removing clay, silt, and organic impurities from natural river sand. The system is particularly valuable for producing standard-compliant sand for building foundations, road bases, and architectural mortar, while its water-efficient design makes it suitable for mining operations, river dredging projects, and environmental remediation sites that require sustainable processing of alluvial deposits. The washed output meets technical specifications for modern engineering applications including bridge construction, land reclamation, and industrial flooring systems.

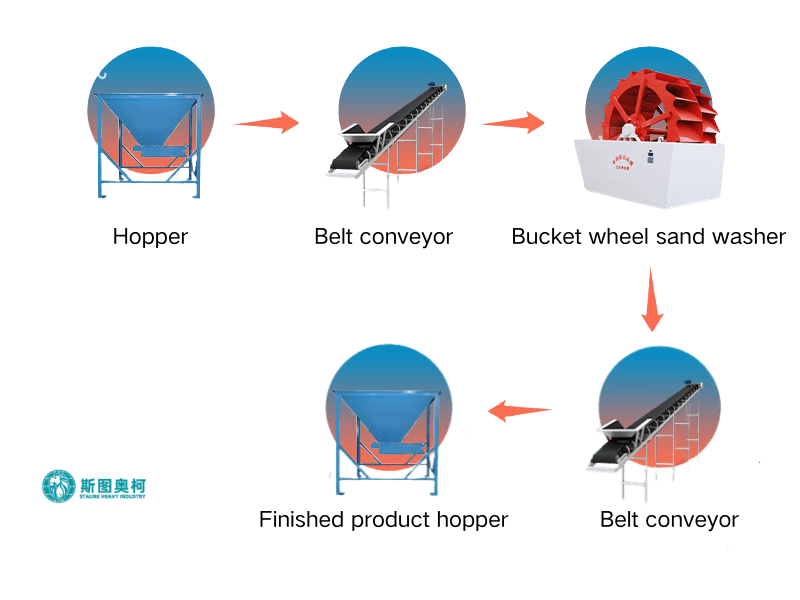

Sand Washing Plant Working principle

1.Feeding Raw Material

The raw river sand is continuously fed into the production line at a rate of 200 tons per hour via the first belt conveyor, ensuring a steady supply to the washing system.

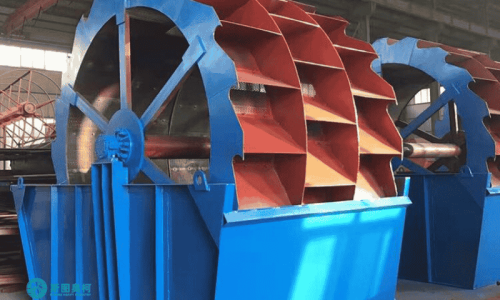

2.Washing Process in Bucket Wheel Sand Washer

The sand is then transferred into the bucket wheel sand washer, where rotating buckets lift and tumble the material while water sprays remove impurities such as clay, silt, and organic debris. The gentle agitation ensures effective cleaning without excessive particle breakdown.

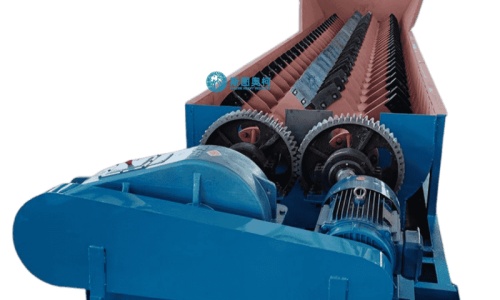

3.Separation of Fines & Dirty Water

During washing, fine particles and contaminants are flushed out with the wastewater, which typically flows into a settling pond or recycling system for water treatment and reuse, minimizing environmental impact.

4.Discharge of Cleaned Sand

The washed sand is discharged onto the second belt conveyor, which transports it to storage or the next processing stage, such as screening or drying, depending on the required final product specifications.

5.Continuous Operation & Efficiency

The entire process operates seamlessly in a closed-loop system, ensuring high productivity (200 t/h) while maintaining low water and energy consumption for cost-effective sand cleaning.

Sand Washing Plant Features

1. High-Efficiency Cleaning

The bucket wheel sand washer provides thorough scrubbing action, effectively removing clay, silt, and organic impurities while preserving sand grain integrity.

2. Large Processing Capacity

Designed for continuous operation at 200 tons per hour, meeting high-volume demands for construction and industrial sand production.

3. Water-Saving Design

Optimized water circulation minimizes consumption, with optional recycling systems to reduce environmental impact.

4. Low Maintenance & Robust Construction

Heavy-duty materials and simple mechanics ensure long service life with minimal downtime for wear part replacement.

5. Automated Operation

Seamless conveyor-to-washer integration enables smooth material flow without manual intervention, improving safety and consistency.

6. Adjustable Cleaning Intensity

The bucket wheel speed and water flow can be modified to handle varying contamination levels in feed material.

7. Compact Layout

Modular design saves space while maintaining full functionality for easy installation in sand plants or mobile setups.

8. Quality Output Control

Produces uniformly clean sand meeting international standards for concrete, mortar, and other construction applications.