Background

A Pakistani client, Mr. Previn, is the owner of the construction industry. He consulted our company for 100tph quartz sand washing production line. Quartz sand is a kind of natural mineral particles with silica (SiO₂) as the main component, and its color is usually white or translucent. The crushed quartz sand is often attached with impurities such as clay and weathered layer, which can be effectively removed by washing with water, so that the SiO₂ content can be increased from 90% to over 98%, and the content of iron oxide (Fe₂O₃) can be reduced by strong water scouring and friction, which is widely used in the fields of industry, architecture and science and technology.

Solutions

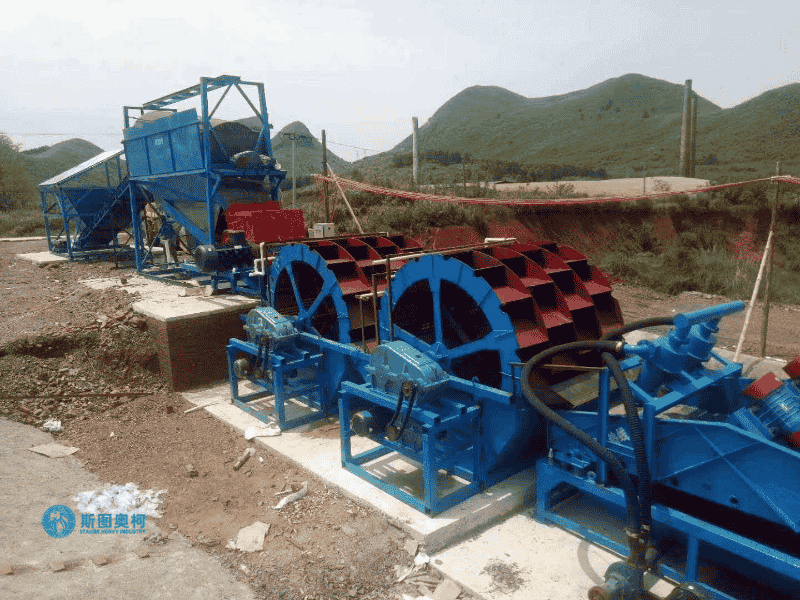

First quartz sand be transported by belt conveyor to a trommel screen that removes oversized debris (>5mm) through rotating drum action while classifying material by size. The screened sand then enters a wheel sand washer where counter-rotating impellers vigorously agitate the material in a water bath, effectively scrubbing away 95%+ of clay and organic impurities using 3-5m³ of water per ton processed. The resulting slurry flows into a fine sand recovery system combining hydrocyclones and dewatering screens to separate and recover 85-90% of valuable 0.075-0.6mm particles from the wastewater stream, with the cleaned sand (0-5mm, ≤3% silt content) discharged via final belt conveyor while 80% of process water is recycled through sedimentation tanks. The entire system features PLC automation to precisely control feed rates, water volumes and operational parameters, with the trommel's pre-screening significantly improving washing efficiency by eliminating oversized contaminants early in the process, and the closed-loop water design reducing fresh water consumption to ≤1.5m³ per ton of processed material.

Case Photos

Feedback

Mr. Previn's feedback on 100tph quartz sand washing production line: the quartz sand processed through this washing production line emerges thoroughly cleaned and purified, with all surface impurities and clay contaminants effectively removed. The final product demonstrates excellent uniformity in particle size distribution and consistent quality throughout the production batch. The system maintains stable processing capacity while reliably recovering fine sand particles that would normally be wasted. Through efficient water recycling, the line achieves environmentally