Overview

Aggregate Washing Plant Introduction

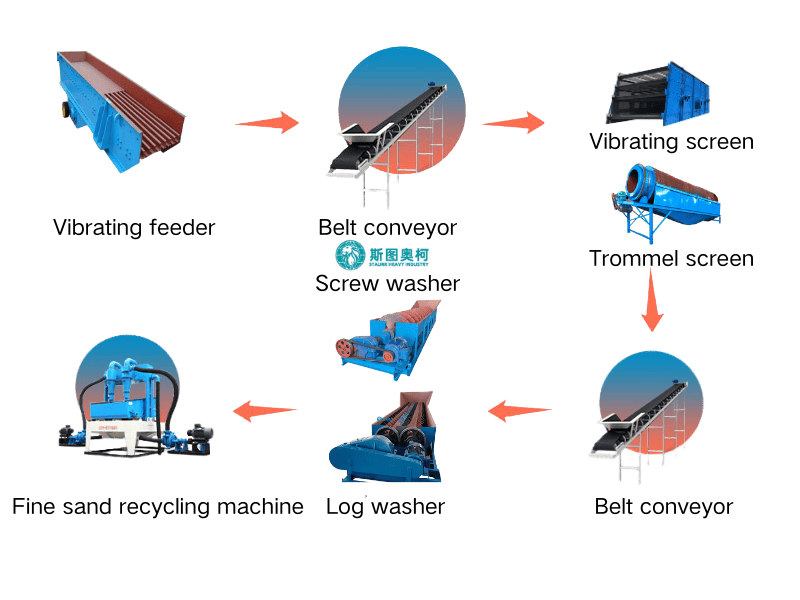

An aggregate washing plant is an industrial facility designed to clean, grade, and dewater raw materials such as crushed rock, or recycled construction aggregates. Its primary function is to remove unwanted materials like clay, silt, dust, and organic impurities through a screw washer /log washer. Key components typically include a vibrating screen/trommel screen for screening, a screw washer/log washer for washing, and a dewatering screen to reduce moisture content. By producing high-quality, specification-ready sand and aggregates, this plant is essential for ensuring the strength and durability of concrete and asphalt in the construction industry, while also promoting water recycling and minimizing environmental impact.

Aggregate Washing Plant Working Principle

1.Feeding and Preliminary Screening

The process begins by feeding the aggregate into the vibrating feeder and entering the vibrating screen/trommel screen through the conveyor belt. Entering the vibrating screen/trommel screen is usually referred to as a "peeling" or "sizing" screen. This initial stage will remove most of the smaller, compliant materials and separate out larger fragments or oversized rocks that may require further crushing, ensuring that the washing equipment only processes necessary materials.

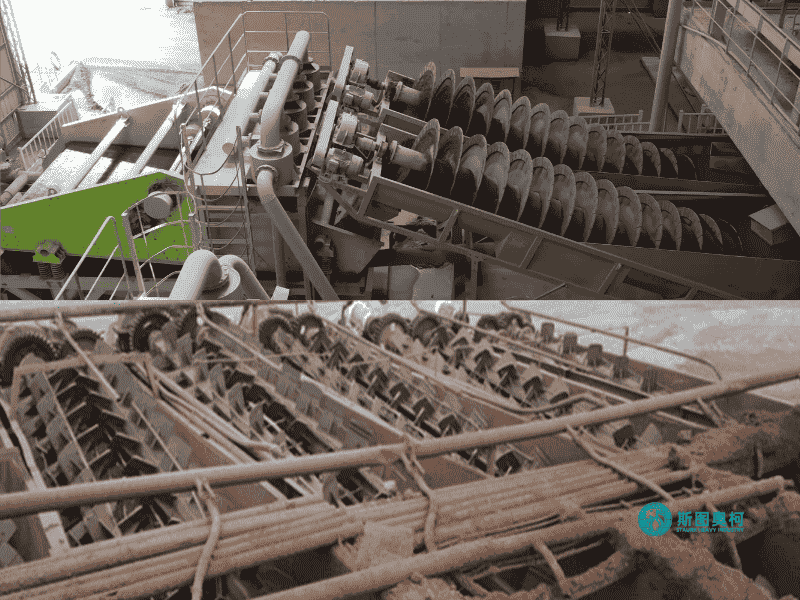

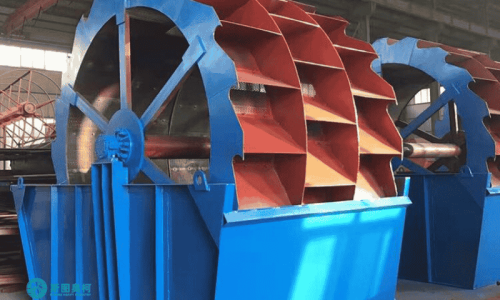

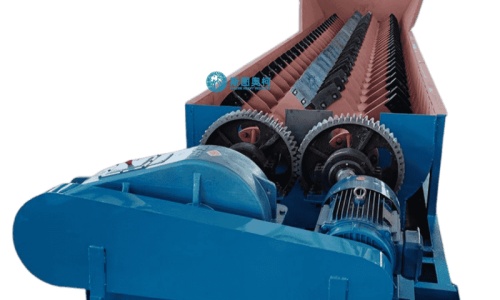

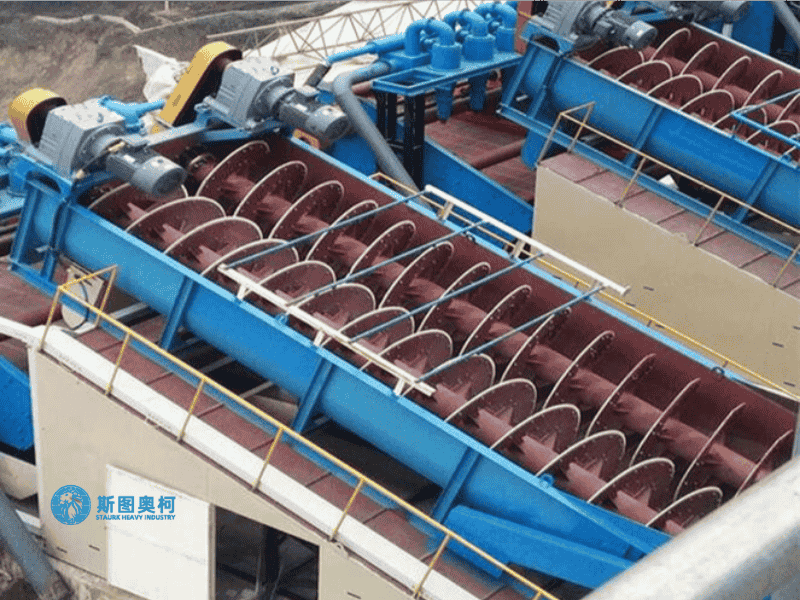

2.Washing and Scrubbing

The pre-screened material requiring cleaning is then directed to washing units. This can include log washer for heavily clay-bound material or screw washer. In these machines, the aggregate is vigorously mixed and tumbled in water. The mechanical action of the rotating screw or paddles creates friction between the particles, effectively dislodging and breaking down stubborn clay, silt, and other coatings adhered to the stone or sand surface.

3.Dewatering and recovery

After washing, the clean aggregates are sent to the fine sand recycling machine. Firstly, the aggregates are subjected to high-frequency vibration of the dewatering screen to remove moisture. The wastewater containing fine sand from the screw washer/log washer enters the cyclone to recycle the fine sand, significantly reducing its moisture content and facilitating storage and transportation.

4.Water Management and Recycling

The wastewater containing the suspended fine particles (slimes) flows into a settlement system, such as a series of ponds or a large clarifier tank. Here, the solids are allowed to settle out. Clean water is then recycled from the top of the settlement area back into the washing plant for reuse, which is crucial for conservation and reducing operational costs.

Sand Washing Plant Features

1. Enhanced Product Quality and Value

The primary advantage is the significant improvement in product quality. By effectively removing clay, silt, dust, and other contaminants, the plant produces clean, high-quality aggregates. This cleanliness is critical for achieving superior bonding in concrete and asphalt, leading to stronger and more durable construction materials. Consequently, the washed aggregate commands a higher market price and meets strict industry specifications.

2. Environmental Compliance and Sustainability

A modern washing plant incorporates advanced water recycling and silt management systems. It allows for up to 90% of the process water to be treated and reused, dramatically reducing freshwater consumption. Furthermore, it effectively captures fine particles, preventing water pollution and enabling the controlled disposal or potential reuse of silt, which minimizes the operation's environmental footprint.

3. Increased Versatility and Resource Utilization

These plants enable the processing of a wider range of raw materials that would otherwise be unusable. This includes low-grade deposits with high clay content and, importantly, construction and demolition waste. By washing recycled concrete and rubble, the plant transforms waste into valuable secondary aggregates, promoting a circular economy and reducing the need for virgin material extraction.

4. Improved Operational Efficiency and Market Reach

By automating the cleaning and grading process, a washing plant ensures consistent, specification-compliant output at a high volume. This efficiency reduces manual labor and increases overall production capacity. The ability to produce a variety of graded, premium products—from coarse gravel to fine sand—allows producers to access more demanding and profitable market segments.