Background

In the Amazon River basin of Brazil, David runs a building materials company that mines abundant river sand reserves, but naturally mixes a large amount of pebbles and gravel with high mud content, making it difficult for existing simple equipment to effectively separate impurities. The quality of the finished sand is unstable and cannot meet the standard requirements for concrete production. Therefore, it is necessary to remove stones, strip soil, and control moisture content to improve product grade.

Solutions

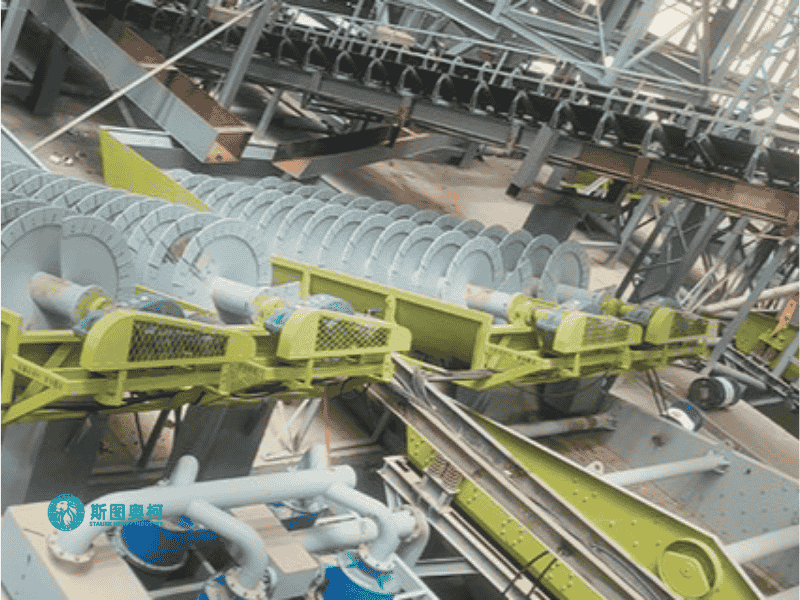

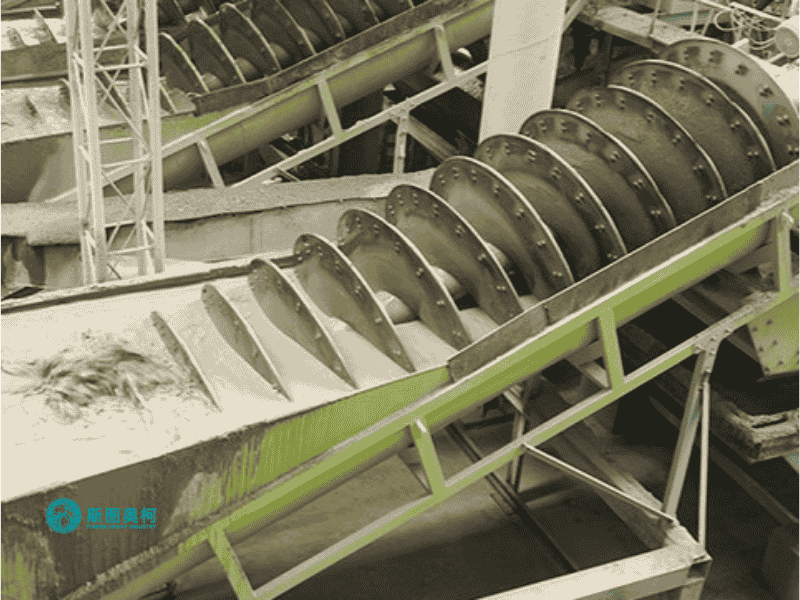

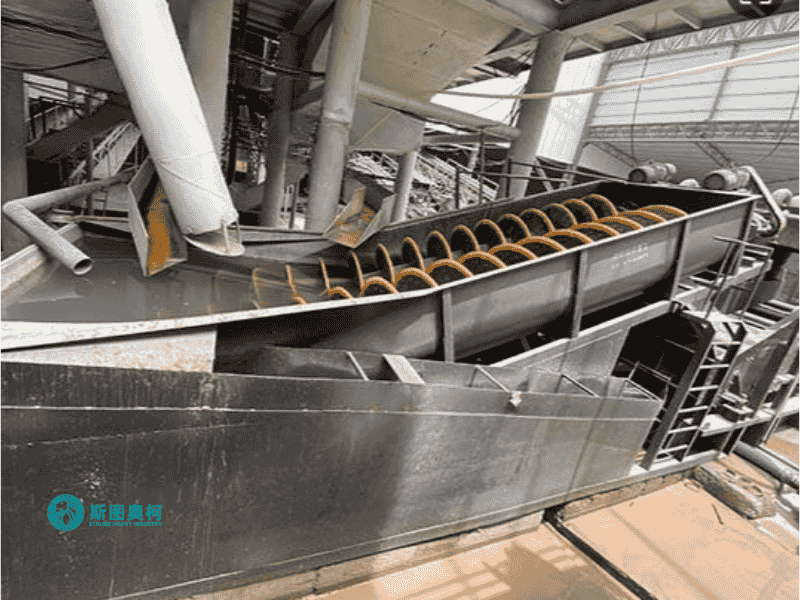

We provide a set of solutions with integrated screening, cleaning and dewatering functions. The raw materials are pre-screened with high efficiency by vibrating screen, and large-size stones are separated and directly output as aggregate products. The sand-gravel mixture that meets the requirements enters the screw washer, and the clay impurities are completely removed by the strong kneading of the double screw blades and the water flow scouring. The washed sand is transported to high-frequency dewatering screen through the chute for severe vibration dehydration, and finally two commodities, namely clean and dry fine sand and specification stones, are produced synchronously.

Case Photos

Feedback

We are very satisfied with this customized sand washing and dewatering line. Its high-efficiency vibrating screen separates valuable stones as by-products in advance, and the screw washer completely removes stubborn clay impurities from river sand. The strong dewatering screen reduces the water content of finished sand to the ideal standard. The whole production line not only perfectly solves the purification problem of stone-bearing river sand, but also creates additional benefits through resource utilization, which completely exceeds our expectations.