Overview

Sand Washing Plant Introduction

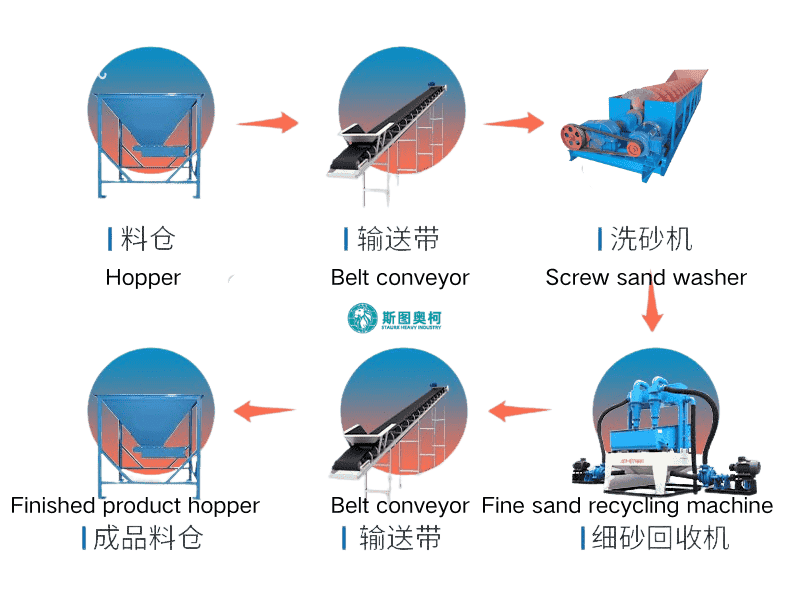

This silica sand processing line begins with raw material being uniformly fed from a storage hopper onto a belt conveyor, which transports it into a screw sand washer. Inside the washer, the rotating screw continuously agitates and scrubs the material while high-pressure water sprays effectively remove clay and impurities. The cleaned sand is conveyed upward by the screw and discharged, while wastewater containing fine particles overflows into the collection tank. This slurry is then pumped to a fine sand recovery unit, where a hydrocyclone separates valuable silica fines based on particle size; the recovered sands are dewatered on a high-frequency vibrating screen, while the overflow water is directed to a sedimentation system for clarification and reuse. The final washed and dewatered silica sand product, with low moisture content and consistent quality, is stockpiled for shipment.

Sand Washing Plant Working Principle

1.Uniform Feeding & Conveying

Raw silica sand is consistently fed from a storage hopper onto a belt conveyor. The conveyor steadily transports the material into the inlet of the screw sand washer, ensuring a stable and continuous processing rate.

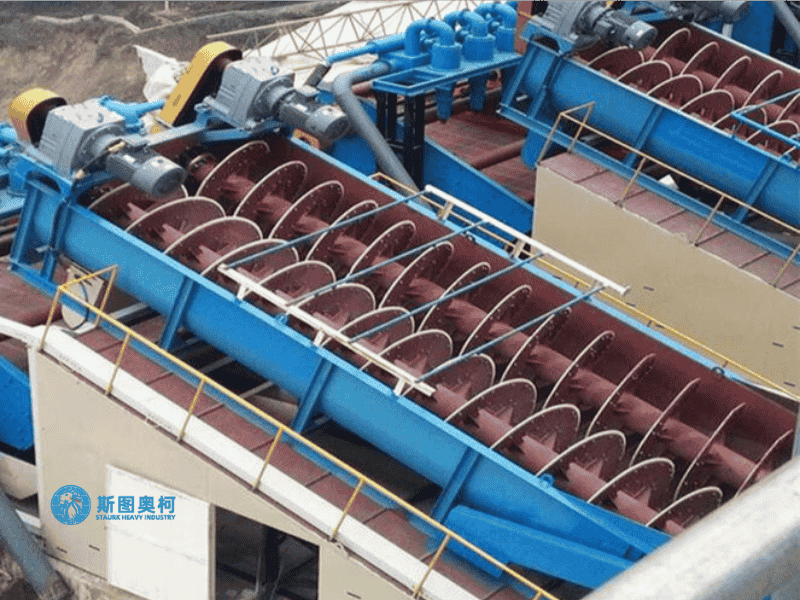

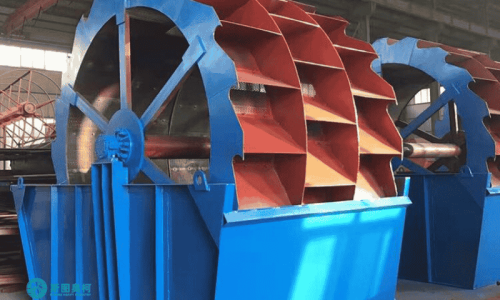

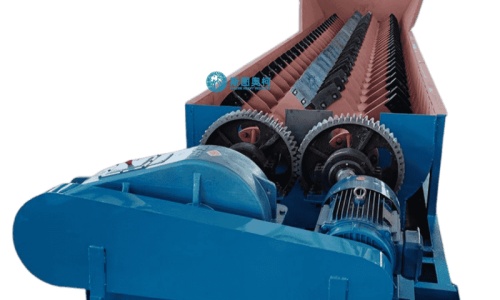

2.Washing & Scrubbing

Inside the screw sand washer, a rotating screw shaft continuously lifts, agitates, and tumbles the sand. Concurrently, high-pressure water sprays target the material, effectively breaking down and dislodging clay coatings, organic impurities, and other contaminants from the silica sand particles through intense mechanical friction and hydraulic scouring.

3.Preliminary Dewatering & Discharge

The cleaned sand, now freed from most impurities, is carried up the inclined trough by the rotating screw and discharged from the outlet. During this ascent, free water drains away, achieving preliminary dewatering of the coarse and medium sand fractions.

4.Fines Recovery & Classification

The wastewater containing fine silica particles and suspended clays overflows from the washer into a sump. This slurry is pumped under pressure to the fine sand recovery unit, specifically a hydrocyclone. Inside the cyclone, centrifugal force separates the heavier, valuable fine sand particles from the lighter clay and silt.

5.Final Dewatering of Fines

The concentrated slurry of fine sand discharged from the bottom of the hydrocyclone is directed onto a high-frequency dewatering vibrating screen. The screen's rapid vibrations efficiently remove water, producing a damp, manageable product with significantly reduced moisture content.

6.Water Circulation & Clarification

The overflow (mainly water and ultra-fine clays) from the hydrocyclone is sent to a settling system, such as a cascade of ponds or a clarifier. Here, solids settle out, and the clarified water is recycled back to the screw washer's spray nozzles and make-up points, creating a closed-loop system that minimizes fresh water consumption.

Sand Washing Plant Features

1.High-Efficiency Cleaning & Impurity Removal

The combination of the screw sand washer's intense mechanical agitation and high-pressure water spray ensures thorough disintegration of clay clusters and effective removal of contaminants, significantly improving the purity and chemical composition of the final silica sand product.

2.Maximized Product Yield and Profitability

The integrated fine sand recovery unit is crucial. It captures and recovers valuable 40-200 mesh silica fines that would otherwise be lost as waste, boosting overall production yield and transforming a waste stream into a profitable product.

3.Significant Water Conservation and Closed-Loop Operation

The system is designed for water recycling. The settling ponds or clarifiers treat effluent from the recovery unit, allowing clarified water to be pumped back to the screw sand washer. This drastically reduces freshwater consumption, minimizes environmental impact, and enables operation in water-scarce areas.

4.Consistent, High-Quality Final Product

The process ensures precise control over key quality parameters. The output is clean, well-graded silica sand with low moisture content and consistently low levels of clay, iron, and other impurities, making it ideal for high-value applications like glassmaking.

5.Robust Reliability and Low Maintenance

Comprising equipment like screw sand washer and belt conveyors. Its simple mechanical design ensures high uptime, minimal maintenance requirements, and long service life.

6.Operational Simplicity and Cost-Effectiveness

The layout is straightforward and easy to control, reducing the need for specialized operators. This, combined with low water and energy costs per ton and high yield, results in a low operating cost and a strong return on investment.

7.Compact and Modular Design

The entire line can be designed with a modular structure, facilitating easier transportation, faster on-site installation, and flexibility in layout planning to fit various space constraints.