Background

Gravity separation is a traditional and effective method for recovering gold from ore, especially for processing placer gold or coarse-grained gold deposits. This case study presents a successful application of a gravity separation production line for gold ore beneficiation, highlighting the process flow, equipment selection, and performance results. This gravity separation line processes West African alluvial gold ore (1.5-2.0 g/t) with coarse-grained particles, achieving ≥85% recovery through optimized jig and centrifugal concentration. The robust system delivers high gold recovery while minimizing environmental impact and operational costs.

Solutions

This optimized gravity separation line processes 100TPH of West African alluvial gold ore (1.5-2.0 g/t) through a sequential system beginning with primary crushing via jaw crusher to reduce ore below 50mm, followed by vibrating screening to recycle oversize material, with optional ball mill grinding for semi-weathered ores. The core gravity separation employs a jig for coarse gold concentration (60-70% recovery), shaking table for fine gold from jig tailings, and Knelson centrifugal concentrator to boost fine particle recovery by 15-20%, achieving an overall 87% gold recovery rate. The process concludes with tailings dewatering for water recycling and waste rock disposal, followed by concentrate smelting into gold bullion, delivering an environmentally-friendly solution with no toxic chemicals, low operating costs ($12-15/ton), and fast ROI (payback <8 months) through efficient equipment including jaw crusher, jig separator, centrifugal concentrator, dewatering screen and smelting furnace.

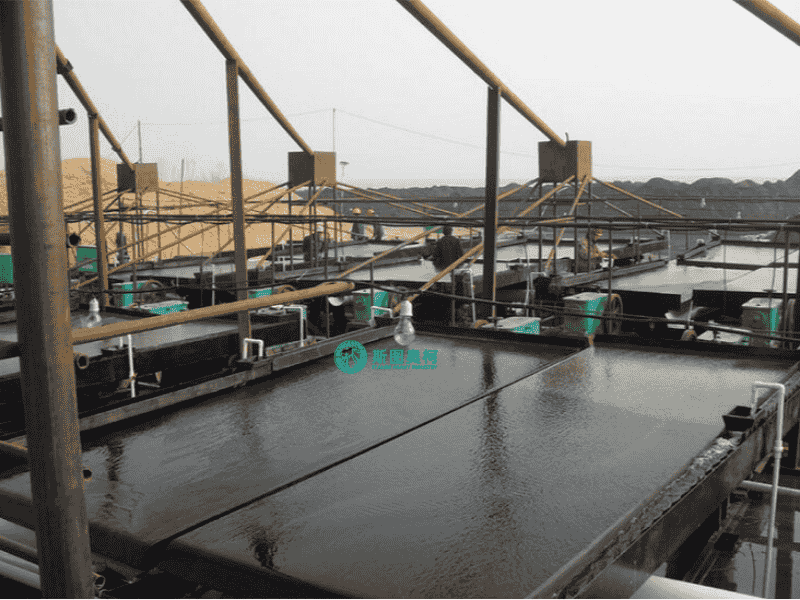

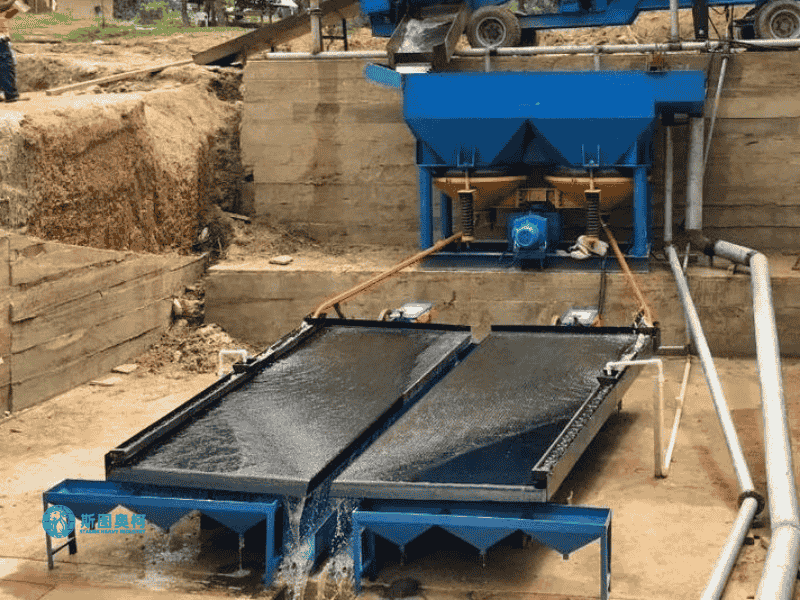

Case Photos

Feedback

This gravity separation line has proven to be an exceptionally efficient and environmentally responsible solution for our alluvial gold operation. The optimized process flow and equipment selection delivered outstanding results - we consistently achieve high recovery rates while maintaining minimal environmental impact. The complete absence of toxic chemicals like cyanide significantly reduced our compliance risks and operational costs. Most importantly, the system's robust design ensures reliable performance even with fluctuating feed grades, making it perfect for West African alluvial deposits. We've gained both economic and sustainability benefits from this solution.