Background

Mr. Leo are from Canada, he needs a mobile impact crushing station, its capacity is 150 tons per hour. The material is quartz rock, the maximum size is 500mm, the granularity required for discharging is 30-50mm. The space of the construction site is limited, and it needs to be moved after a period of operation, and the terrain of the construction site is complex.

Solutions

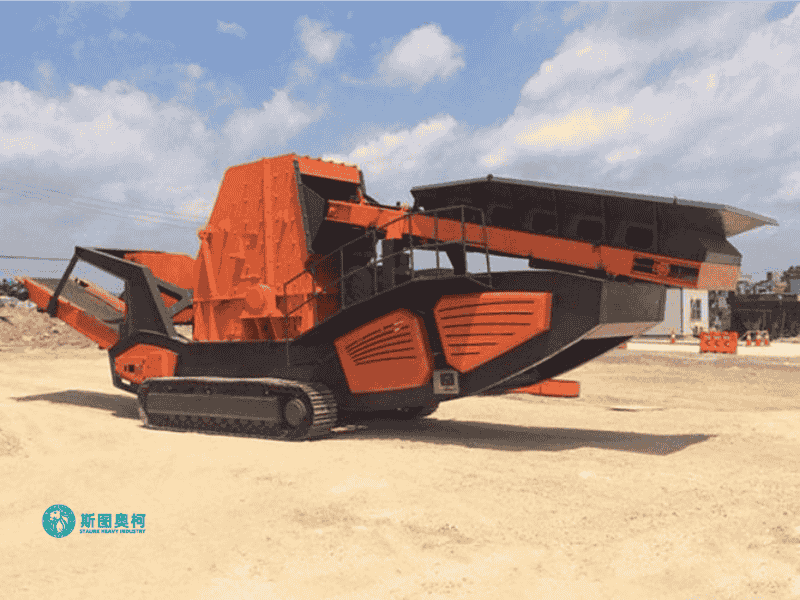

According to the requirements of client, we choose a 150 tons per hour crawler-type impact crushing station. firstly, feeding raw materials quartz rock through a vibrating feeder that pre-screens and evenly delivers 500mm chunks into the impact crusher, where high-speed rotating blow bars fracture the material against adjustable impact aprons to achieve 30-50mm output size. Crushed aggregate is discharged via the main conveyor while optional side belts remove impurities, with the entire self-propelled system capable of on-site relocation via remote-controlled crawler tracks, featuring real-time monitoring of operational parameters like throughput and bearing temperature, all while maintaining mobility between job sites and incorporating dust suppression systems for environmental compliance.

Case Photos

Feedback

Mr. Leo's feedback on mobile impact crushing station: The crushing station can adapt to our site operation, and the equipment runs stably. The whole crushing station has achieved the required effect, and the equipment in your factory is commendable.