Background

A South African client, Mr. David wants to build one gold ore gravity separation plant, its capacity is 1-2 tons per hour. Client's gold mine belongs to the natural gold which is easy to dissociate in the vein mine, and the mine belongs to the small mine, and the funds are limited. The customer hopes to collect gold quickly.

Solutions

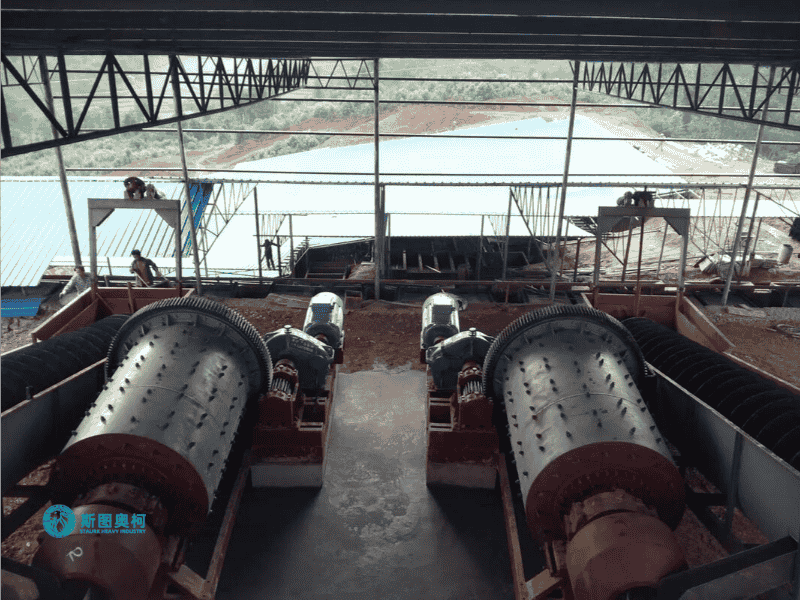

The 1-2 ton per hour gold ore gravity separation production line begins with primary crushing using a jaw crusher (PE-150×250) to reduce raw ore to ≤50mm, followed by secondary crushing with a fine crusher (hammer crusher) to achieve ≤10mm particle size. The material is then ground in a ball mill (MQG900×1800) to ~0.5-1mm to liberate free gold, optionally paired with a spiral classifier or hydrocyclone for closed-circuit grinding control. The ground ore is fed into a Knelson concentrator (STLB30) to recover free gold >30μm via centrifugal force (60-200G), with the concentrates further upgraded on a shaking table (6-S) to target 0.1-2mm gold particles. Combined concentrates are dried and smelted into gold bars, while tailings are discharged or reprocessed.

Case Photos

Feedback

Mr. David's feedback on 100TPD gold tailings CIP production line: The production line has the advantages of high efficiency, no need of complicated process, low investment cost, quick profit, small floor space and rapid deployment of production.