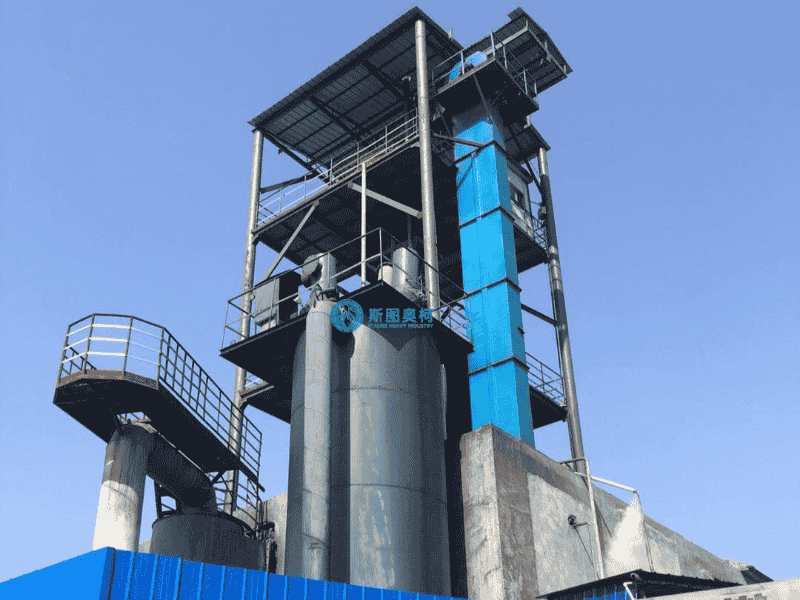

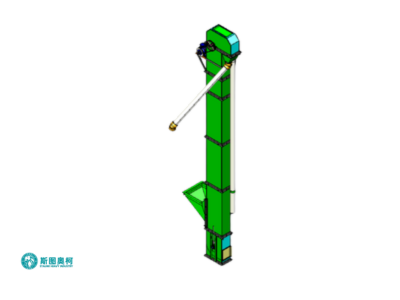

Bucket Elevator

Capacity: 1-1000 TPH

Feeding Size: 0-100 mm

Discharging Size: 0-100 mm

Handling Materials: Ore, sand and gravel, cement, etc

Bucket elevator lifts bulk materials (e.g., grains, ores) via motor-driven buckets, handling 1-1,000t/h with 0-100mm particle sizes. Ideal for high-efficiency lifting up to 100m, it consumes 50-70% less energy than pneumatic systems. Avoid sticky or explosive materials.

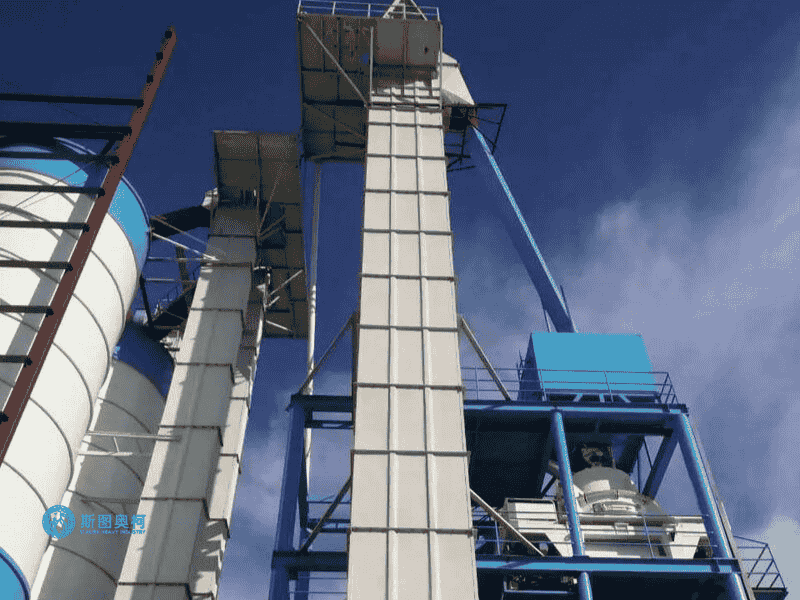

Advantages

01.

High Efficiency

Lifts materials up to 100m vertically with 50-70% less energy than pneumatic systems, ideal for compact plant layouts.

02.

Gentle Handling

Continuous bucket designs prevent particle breakage for fragile materials (fertilizer grains, charcoal).

03.

Large Capacity

Handles 1-1,000t/h throughput, from fine powders (0.1mm) to coarse lumps (100mm), adapting to diverse industries.

04.

Low Maintenance

Robust steel chains/buckets last 5-8 years in abrasive applications (cement/clinker) with minimal lubrication.

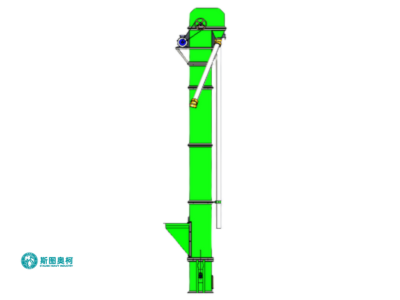

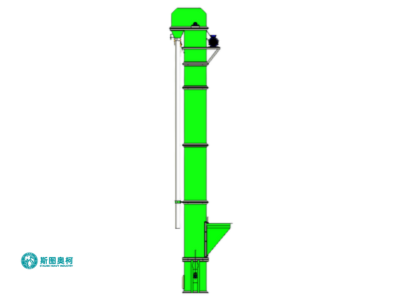

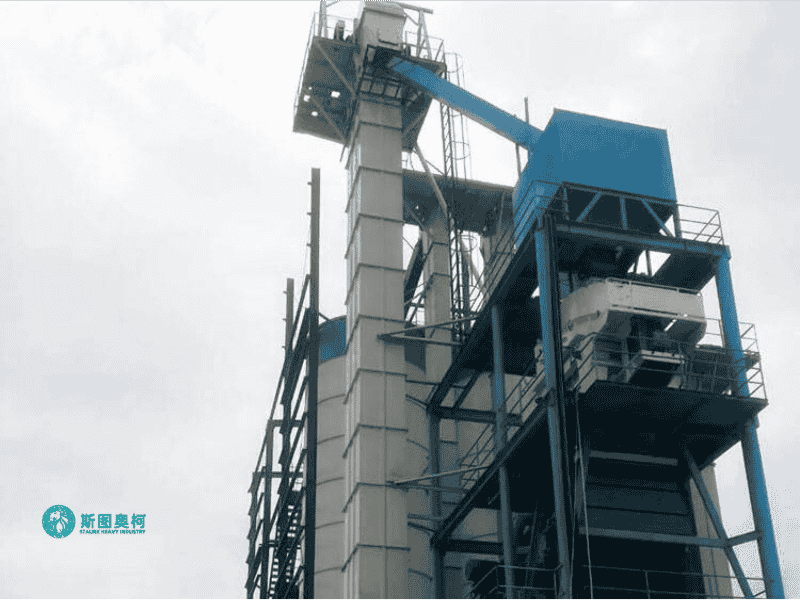

How Does A Bucket Elevator Work

1. Material Loading: Bulk goods (0–100mm) are fed into the boot section, where moving buckets scoop them up (centrifugal type) or are pre-filled (continuous type).

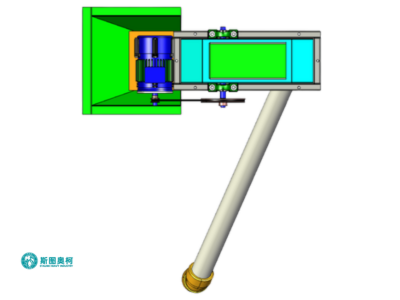

2. Vertical Traction: Motor-driven chains/belts lift the buckets upward at 0.5–4 m/s, guided by steel casing to prevent swaying or spillage.

3. Discharge Mechanism: At the top: Centrifugal discharge: Buckets flip, ejecting material via centrifugal force (for free-flowing powders); continuous discharge: Buckets tip gently, minimizing breakage (for fragile lumps).

4. Return Cycle: Empty buckets descend outside the casing, completing the loop. Sealed design contains dust.

Applications

Models

Model | Capacity (t/h) | Lifting Height (m) | Bucket Type | Belt/Chain Type | Power (kW) | Bucket Speed (m/s) | Material | Remarks |

BE200 | 10-20 | 10-30 | Deep Bucket | Rubber Belt | 3.0-7.5 | 1.0-1.5 | Light Powdery Materials | Suitable for light materials like grain and flour. |

BE300 | 20-50 | 15-40 | Shallow Bucket | Steel Chain | 7.5-15 | 1.2-1.8 | Granular Materials | Ideal for granular materials such as sand and gravel. |

BE400 | 50-100 | 20-50 | Deep Bucket | Rubber Belt | 15-22 | 1.5-2.0 | Heavy Powdery Materials | Designed for heavy powdery materials like cement and fly ash. |

BE500 | 100-200 | 30-60 | Shallow Bucket | Steel Chain | 22-37 | 1.8-2.5 | Abrasive Materials | Suitable for abrasive materials such as ore and crushed stone. |

BE600 | 200-300 | 40-80 | Deep Bucket | Rubber Belt | 37-55 | 2.0-2.8 | High-Capacity Needs | Used for high-capacity lifting in industries like mining and construction. |

BE700 | 300-500 | 50-100 | Shallow Bucket | Steel Chain | 55-75 | 2.5-3.0 | Heavy-Duty Applications | Designed for heavy-duty applications, such as large-scale mining operations. |