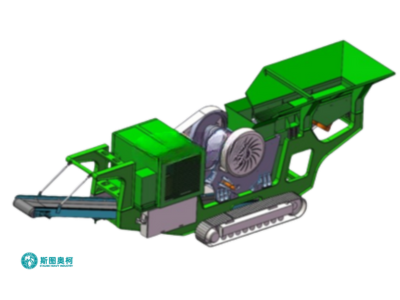

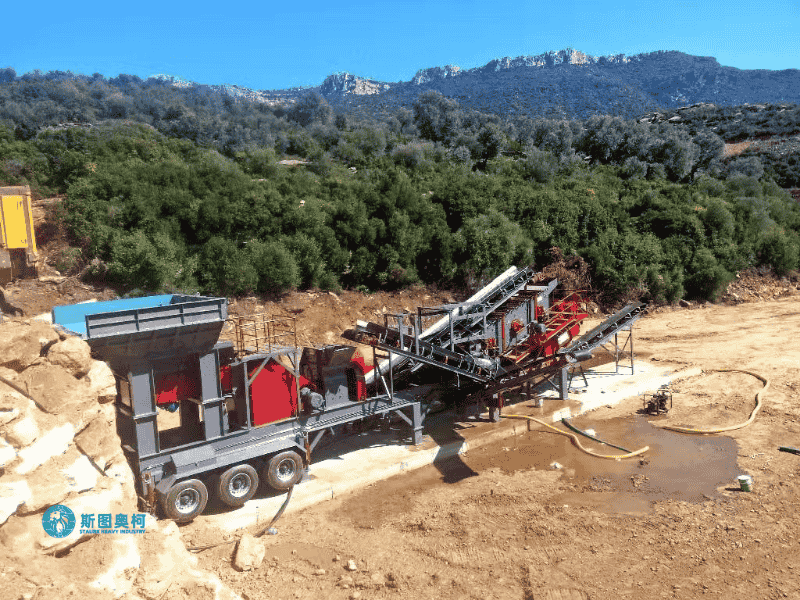

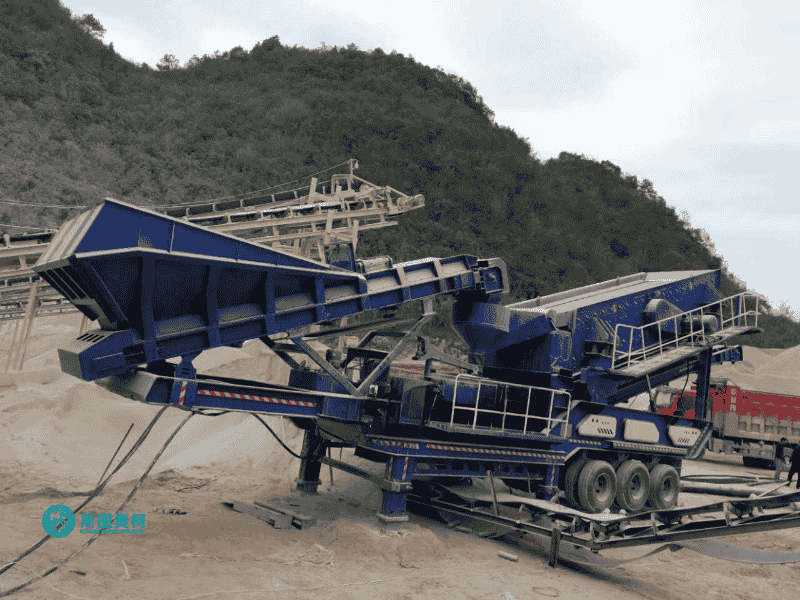

Mobile Crushing Station

Capacity: 50-500 TPH

Feeding Size: ≤650 mm

Discharging Size: 0-60 mm

Handling Materials: Natural Rocks, concrete, bricks, Iron ore, gold ore, copper ore, etc.

A mobile crushing station is a portable rock-crushing plant used in mining, construction, and recycling. It integrates feeders, crushers (jaw/cone/impact), screens, and conveyors on a single chassis for easy transport. It crushes various materials (stone, concrete, ore) into adjustable sizes (0–60 mm) with outputs of 50–500 t/h. Self-propelled and fuel-efficient, it enables on-site crushing, reducing material transport costs. Ideal for flexible, temporary, or remote operations.

Advantages

01.

High Mobility

Self-propelled or towable design allows quick relocation between sites, reducing downtime and transportation costs.

02.

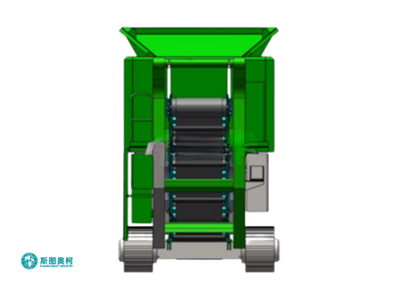

Flexible Configuration

Modular setup (jaw/cone/impact crusher + screen) adapts to various materials and output size requirements.

03.

On-Site Crushing

Processes materials directly at mining, construction, or demolition sites, eliminating hauling needs.

04.

Fast Setup

Fully pre-assembled components enable operational readiness within hours, boosting efficiency.

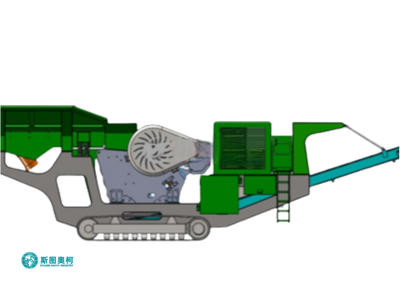

How Does A Mobile Crushing Station Work

1. Feeding & Pre-Screening: Material is loaded into the hopper and pre-screened by a vibrating feeder, removing fine particles to optimize crushing efficiency.

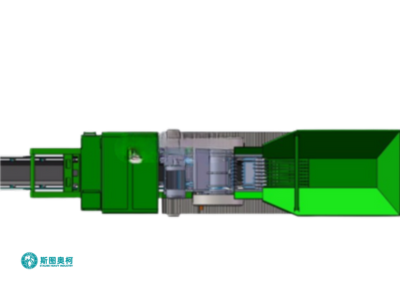

2. Primary Crushing: Large rocks are crushed by the jaw/impact crusher into smaller pieces (100–300 mm), preparing them for further processing.

3. Secondary Screening/Crushing: Material is conveyed to a cone/impact crusher for finer crushing (0–60mm) and screened to separate desired aggregate sizes.

4. Discharge & Recycling: Finished products are stockpiled via conveyors, while oversized material is recirculated for re-crushing, ensuring minimal waste.

Applications

Models

Model | Crushing Capacity (TPH) | Feed Size (mm) | Power (kW) | Weight (kg) | Dimensions (L x W x H, mm) | Application |

MCS-100 | 100-150 | 500 | 110 | 30,000 | 12,000 x 2,500 x 3,500 | Small-scale mining and quarrying |

MCS-200 | 150-250 | 600 | 160 | 45,000 | 14,000 x 2,800 x 3,800 | Medium-scale aggregate production |

MCS-300 | 250-350 | 700 | 220 | 60,000 | 16,000 x 3,000 x 4,000 | Large-scale mining operations |

MCS-400 | 350-500 | 800 | 300 | 80,000 | 18,000 x 3,200 x 4,200 | Industrial construction projects |

MCS-500 | 500-600 | 900 | 400 | 100,000 | 20,000 x 3,500 x 4,500 | Heavy-duty mining and crushing |