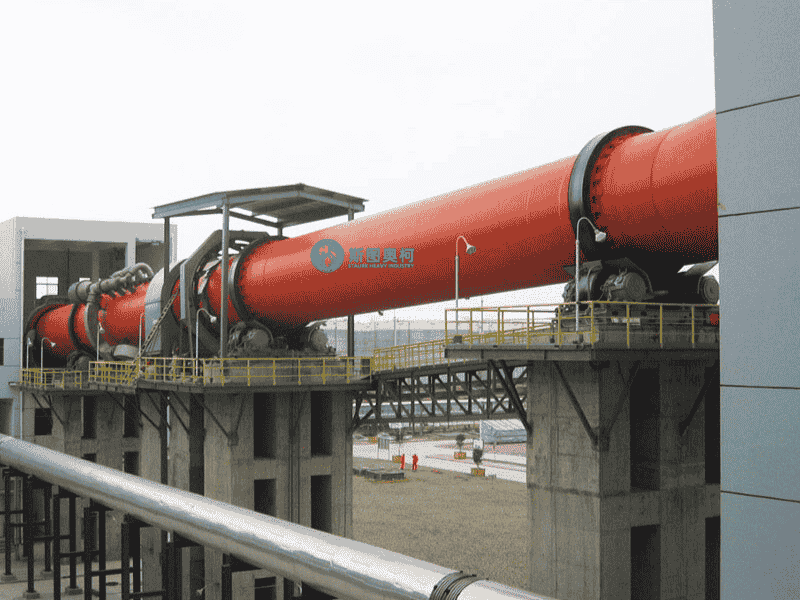

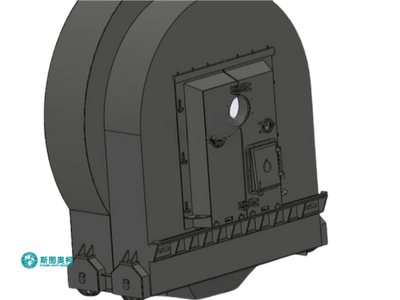

Rotary Kiln

Capacity: 50-5000 TPD

Feeding Size: 0-50 mm

Discharging Size: 0-50 mm

Handling Materials: Raw cement, limestone, iron ore pellets, etc.

Rotary kiln processes materials (0–50 mm) like limestone, ores, and waste at 600–1600°C, producing 50–5,000 t/d of clinker, lime, or metals. Fuel-flexible (gas/coal) with heat recovery, it suits cement/metallurgy but avoids ultrafine feeds.

Advantages

01.

High-Temperature Capability

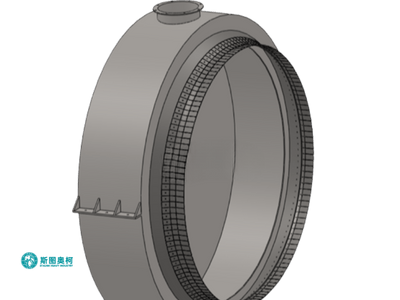

Operates at 600–1600°C for diverse processes (calcination/reduction), with refractory linings lasting 2–5 years under thermal stress.

02.

Fuel Versatility

Supports gas, coal, oil, or waste-derived fuels, adapting to regional energy costs and carbon neutrality goals.

03.

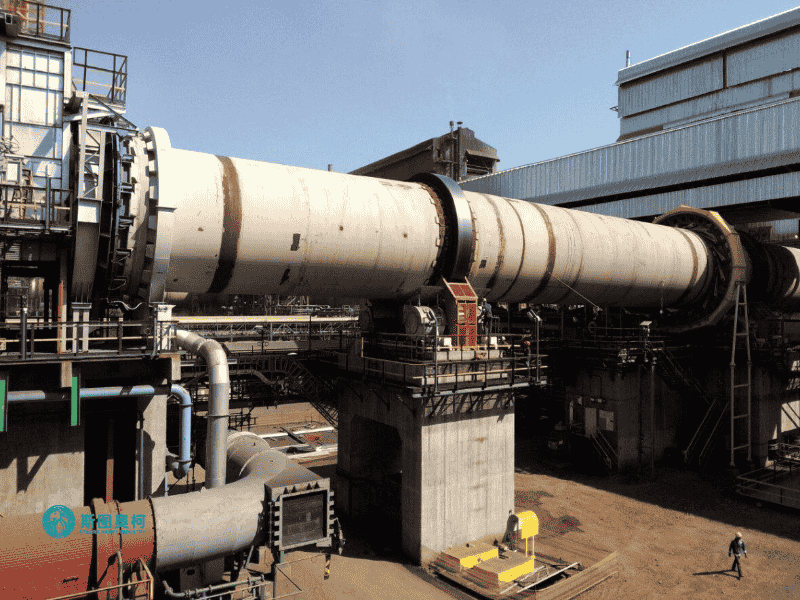

Large-Scale Output

Produces 50–5,000t/day of clinker, lime, or metals, enabling industrial-scale continuous processing.

04.

Heat Recovery

Preheater systems recycle exhaust heat, cutting energy use by 15–20% versus traditional designs.

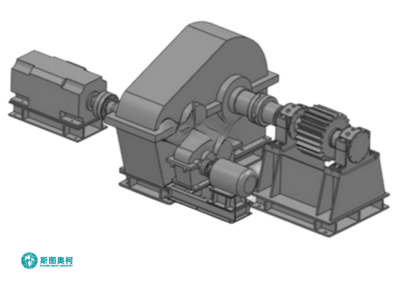

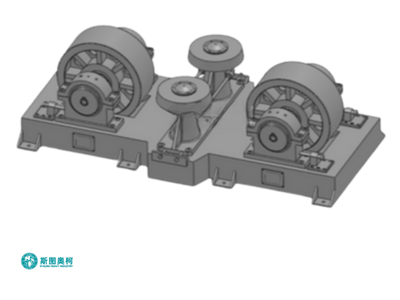

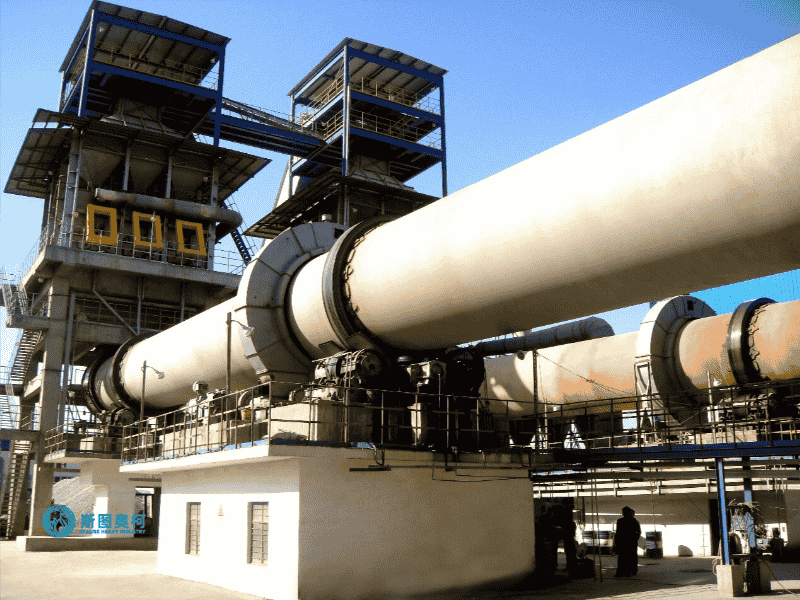

How Does A Rotary Kiln Work

1. Material Feeding: Raw materials (0–50mm) enter the kiln's upper end via a chute or screw conveyor, gradually moving downward due to the kiln's 2–5° inclination.

2. Heat Transfer: Fuel combustion at the lower end generates 600–1600°C heat, while counter-current airflow ensures progressive heating through preheating, calcination, and sintering zones.

3. Product Discharge: Processed material exits the hot end, while exhaust gases preheat incoming feed or are treated for emissions.

Applications

Models

Model | Diameter (m) | Length (m) | Capacity (TPD) | Power (kW) | Rotation Speed (rpm) | Inlet Temperature (°C) | Application |

RK-2.0x30 | 2.0 | 30 | 500-800 | 55 | 0.5-5 | 800-1200 | Cement production |

RK-2.5x40 | 2.5 | 40 | 800-1200 | 75 | 0.5-5 | 800-1200 | Lime production |

RK-3.0x48 | 3.0 | 48 | 1200-2000 | 110 | 0.5-5 | 800-1200 | Iron ore pelletizing |

RK-3.5x55 | 3.5 | 55 | 2000-3000 | 160 | 0.5-5 | 800-1200 | Chemical processing |

RK-4.0x60 | 4.0 | 60 | 3000-5000 | 220 | 0.5-5 | 800-1200 | Large-scale industrial roasting |