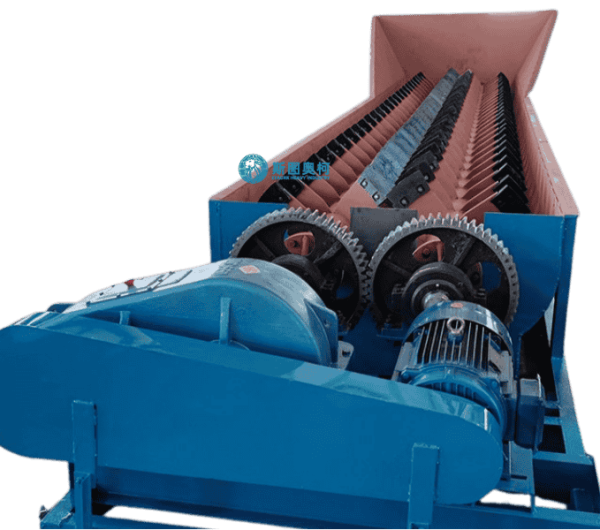

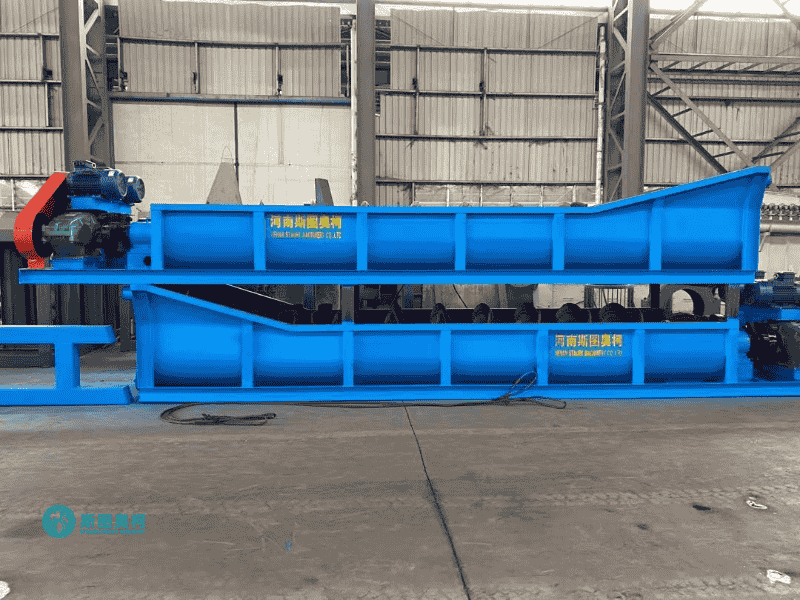

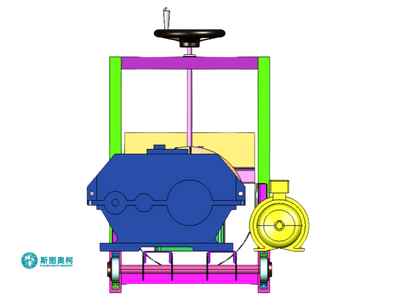

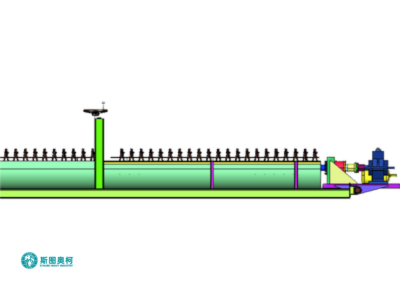

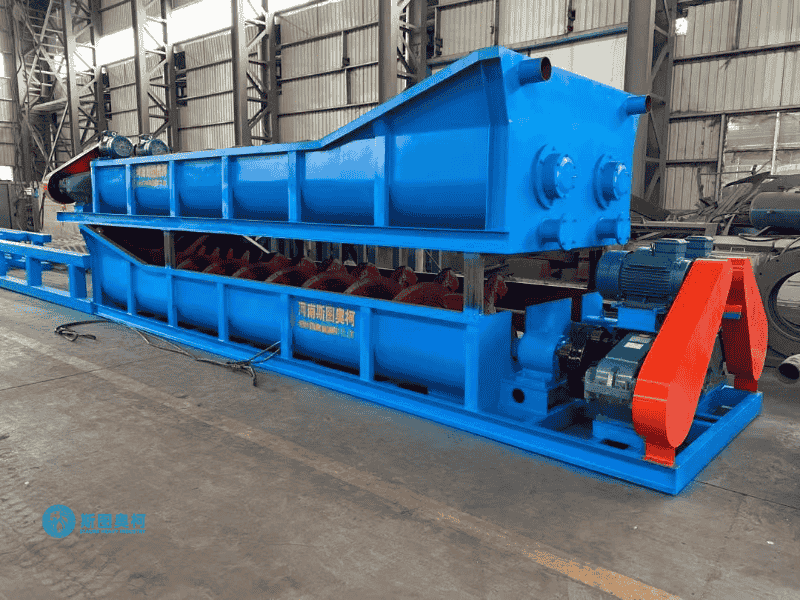

Screw Sand Washer

Capacity: 5-300 TPH

Feeding Size: 0.1-10 mm

Discharging Size: 0.1-10 mm

Handling Materials: Natural river sand, sea sand, gravel sand, etc.

Screw sand washer cleans and classifies sand (0.1–10 mm) by rotating spirals, removing ≤1% clay at 5–300 t/h. Ideal for river/artificial sand washing, it consumes 1–3 m³/t water with optional fine sand recovery. Avoid sticky clay >10 mm.

Advantages

01.

High Cleaning Efficiency

Removes 95%+ clay coatings from 0.1–10mm sand, achieving ≤1% residual impurities for construction-grade material.

02.

Water Conservation

Uses only 1–3 m³ water per ton (vs. 5 m³ in traditional methods) with closed-loop recycling systems.

03.

Dual Functionality

Combines washing and grading in one unit, outputting classified sand (e.g., 0.1–3mm or 1–5mm) directly.

04.

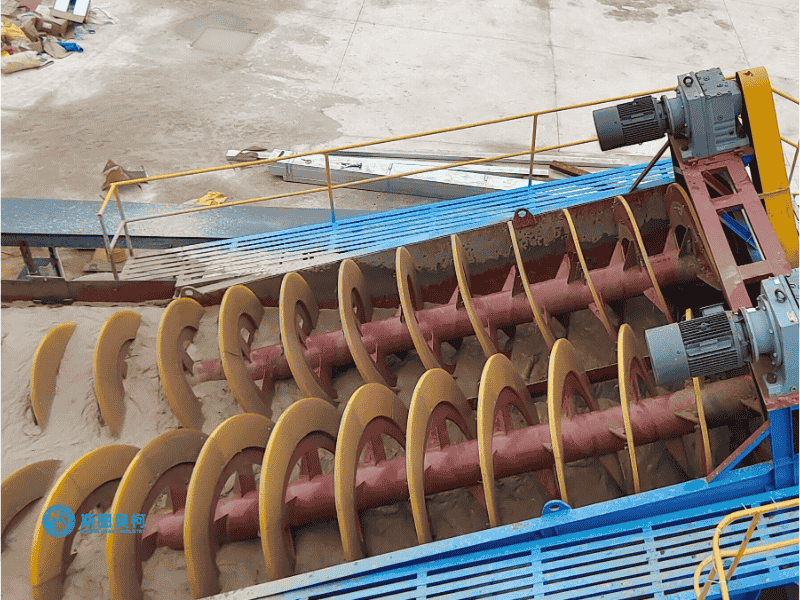

Low Maintenance

Wear-resistant manganese steel spirals last 2–3x longer than standard designs in abrasive silica sand applications.

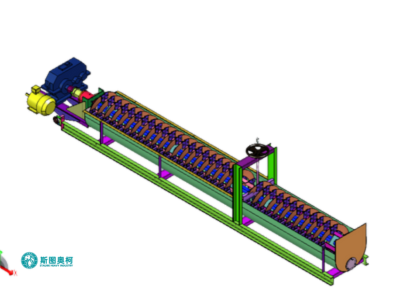

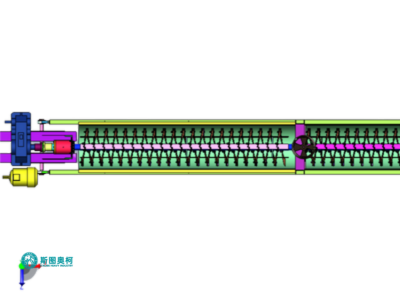

How Does A Screw Sand Washer Work

1. Slurry Feeding: Sand-clay mixture enters the inclined trough, where rotating spirals agitate the material.

2. Mechanical Scrubbing: Sand particles collide under spiral motion, dislodging surface clay while counter-current water flushes impurities.

3. Hydraulic Classification: Clean sand rises along the spiral grooves due to density, while clay slurry overflows the weir at the trough’s lower end.

4. Dehydrated Discharge: Washed sand exits the upper chute (optionally dewatered further via screens), completing the cycle.

Applications

Models

Model | Capacity (TPH) | Spiral Diameter (mm) | Power (kW) | Weight (kg) | Dimensions (L x W x H, mm) | Water Consumption (m³/h) |

SSW-050 | 10-20 | 500 | 3.0 | 1,200 | 3,000 x 1,500 x 2,000 | 10-15 |

SSW-075 | 20-40 | 750 | 5.5 | 1,800 | 4,000 x 2,000 x 2,500 | 20-30 |

SSW-100 | 40-60 | 1,000 | 7.5 | 2,500 | 5,000 x 2,500 x 3,000 | 30-50 |

SSW-150 | 60-100 | 1,500 | 11 | 3,800 | 6,000 x 3,000 x 3,500 | 50-80 |

SSW-200 | 100-150 | 2,000 | 15 | 5,000 | 7,000 x 3,500 x 4,000 | 80-120 |