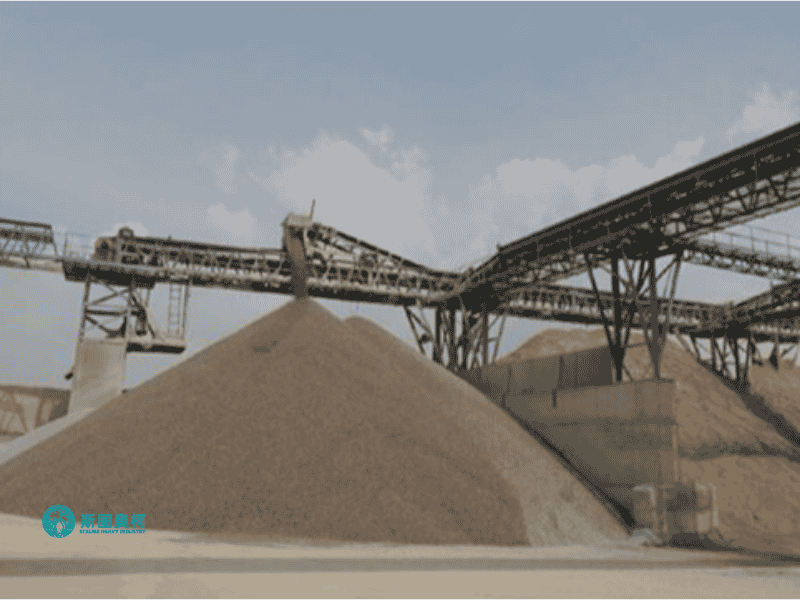

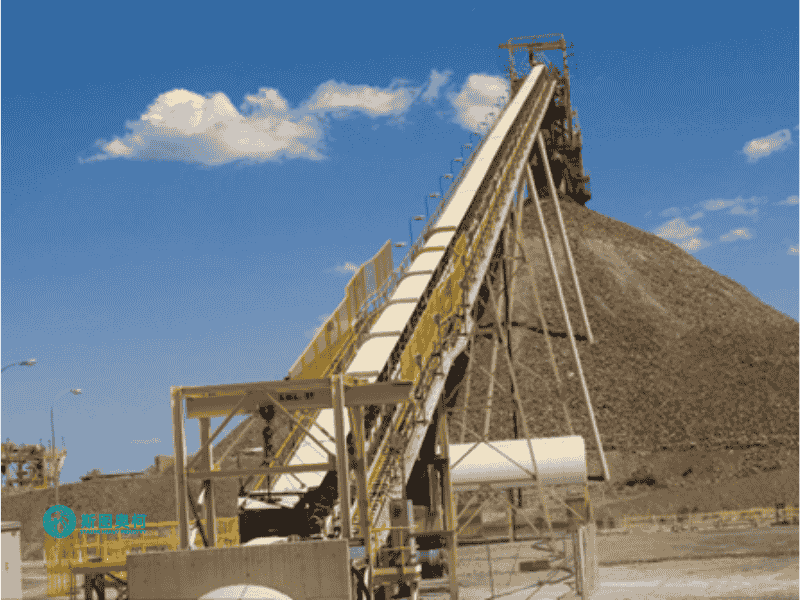

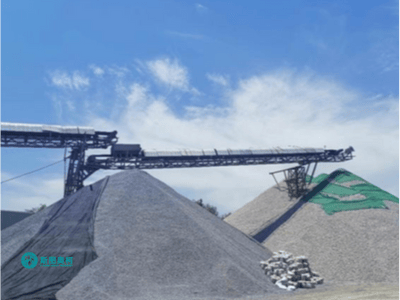

Heap Stacking Equipment

Capacity: 500-20000 TPH

Feeding Size: 0-300 mm

Discharging Size: 0-300 mm

Handling Materials: Ores, aggregates, waste rock, etc

Heap stacking equipment builds organized stockpiles (10–30 m high) via radial or linear conveyors, handling 500–20,000 t/h of ores/aggregates (0–300 mm). Ideal for leaching pads or blending, it ensures precise layering with automated boom control. Avoid sticky or ultra-hot materials.

Advantages

01.

High Efficiency

Automated stacking at 500–20,000t/h reduces manual labor by 80%, with GPS-guided booms ensuring precise pile geometry (10–30m heights).

02.

Blending Accuracy

Layered stacking achieves ±2% material homogeneity, critical for consistent ore grades in leaching/sintering processes.

03.

Space Optimization

Radial designs (360° rotation) minimize footprint, ideal for confined sites like ports or smelter stockyards.

04.

Low Maintenance

Abrasion-resistant liners and modular components extend service life to 50,000+ hours in harsh mining conditions.

How Does A Heap Stacking Equipment Work

1. Material Feeding: Ore/aggregates (0–300mm) are conveyed via belt to a movable boom, which receives real-time positioning data (GPS/laser) for accurate placement.

2. Layered Stacking: The boom rotates (radial) or traverses (linear), depositing material in controlled layers (2–5m thick) to ensure uniform density and permeability.

3. Height Management: Sensors monitor pile geometry, adjusting discharge point to maintain optimal slope (30°–45°) and prevent avalanches.

4. Blending Optimization: For homogenization, multiple material types are stacked in alternating layers, later reclaimed vertically to mix grades.

Applications

Models

Model | Stacking Capacity (TPH) | Stacking Height (m) | Stacking Width (m) | Power (kW) | Conveyor Belt Width (mm) | Application |

HS-500 | 500 | 10 | 20 | 15 | 1,200 | Mining and mineral processing |

HS-1000 | 1,000 | 12 | 25 | 22 | 1,400 | Coal and bulk material handling |

HS-1500 | 1,500 | 15 | 30 | 30 | 1,600 | Cement and clinker stacking |

HS-2000 | 2,000 | 18 | 35 | 45 | 1,800 | Large-scale mining operations |

HS-3000 | 3,000 | 20 | 40 | 55 | 2,000 | Industrial bulk material storage |