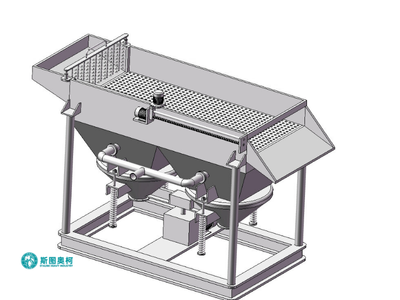

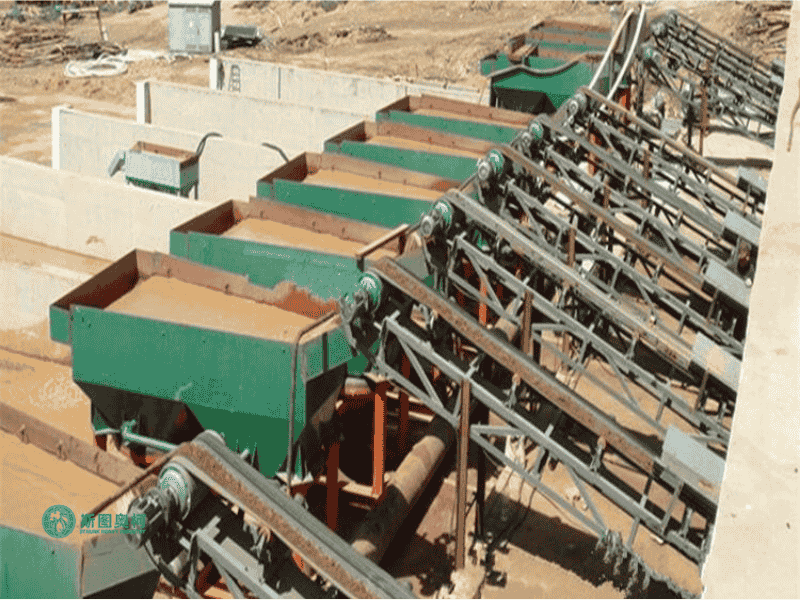

Jigger

Capacity: 5-50 TPH

Feeding Size: 0.5-50 mm

Discharging Size: 80–95%(>0.1mm),70–85%(0.5–2mm)

Handling Materials: Tungsten ore, tin ore, iron ore, manganese ore, chromium ore, gold ore, etc.

Jigger sorts minerals (tungsten, coal) by density using pulsating water flow. It handles 0.5–50mm feed at 5–50t/h, achieving 5–50x enrichment without chemicals. Ideal for coarse particle separation but requires low-clay feeds.

Advantages

01.

High Capacity

Handles coarse feeds (5–50mm) at 5–50t/h, 3–5x faster than shaking tables for similar density separations.

02.

No Reagents

Density-based sorting eliminates chemical use, ideal for eco-sensitive areas or water-restricted sites.

03.

Simple Operation

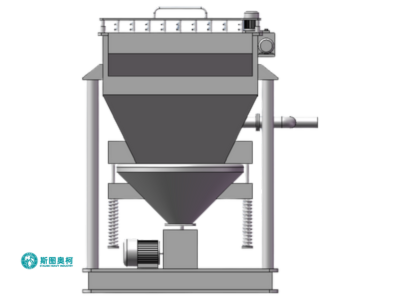

Adjustable stroke (20–50mm) and water pulse frequency (40–100/min) adapt to varying ore types.

04.

Low Energy

Consumes only 2–10kW per unit, making it cost-effective for primary heavy mineral concentration.

How Does A Jigger Work

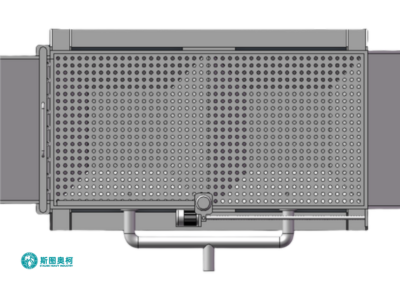

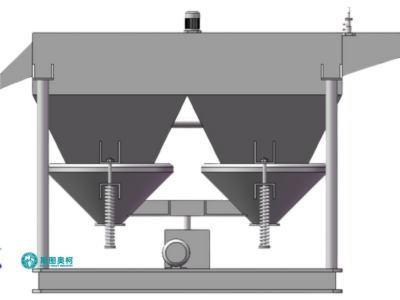

1. Pulsating Bed Formation: Ore (0.5–50mm) is fed onto a screen submerged in water, where alternating upward/downward water flow (40–100 pulses/min) fluidizes the bed.

2. Density Stratification: Heavy minerals (tungsten) sink through the teetered bed to the screen bottom, while lights (e.g., quartz) rise to the top.

3. Continuous Separation: Strokes (20–50 mm) push heavies forward as concentrate; gangue overflows the weir. Adjustable discharge gates control product grades.

4. Middlings Recycling: Intermediate-density particles are internally cycled or sent to secondary jigs for further upgrading.

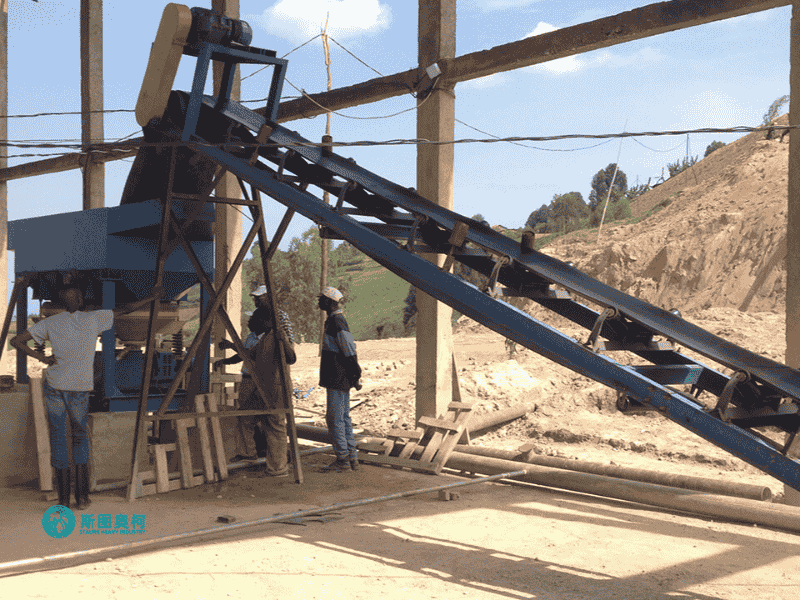

Applications

Models

Model | Feed Size (mm) | Capacity (TPH) | Stroke Length (mm) | Power (kW) | Weight (kg) | Dimensions (L x W x H, mm) | Application |

JG-500 | 10 | 5-10 | 10-20 | 1.5 | 500 | 1,500 x 1,000 x 1,200 | Small-scale mineral separation |

JG-1000 | 20 | 10-20 | 20-30 | 3.0 | 800 | 2,000 x 1,200 x 1,500 | Medium-scale ore processing |

JG-1500 | 30 | 20-30 | 30-40 | 5.5 | 1,200 | 2,500 x 1,500 x 1,800 | Large-scale mining operations |

JG-2000 | 40 | 30-40 | 40-50 | 7.5 | 1,500 | 3,000 x 1,800 x 2,000 | Industrial mineral processing |

JG-2500 | 50 | 40-50 | 50-60 | 11 | 2,000 | 3,500 x 2,000 x 2,500 | Heavy-duty mining applications |