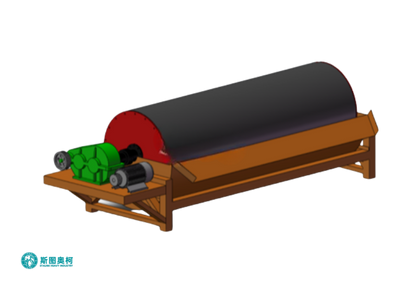

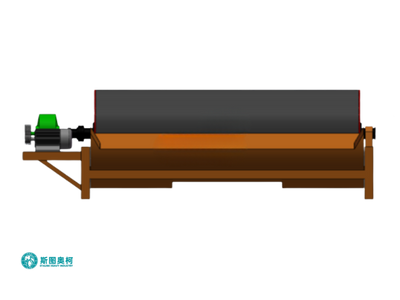

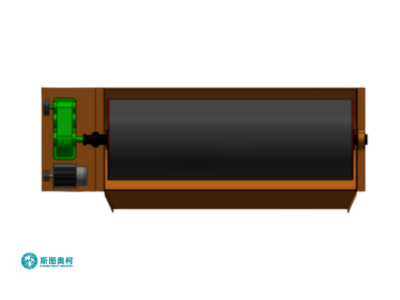

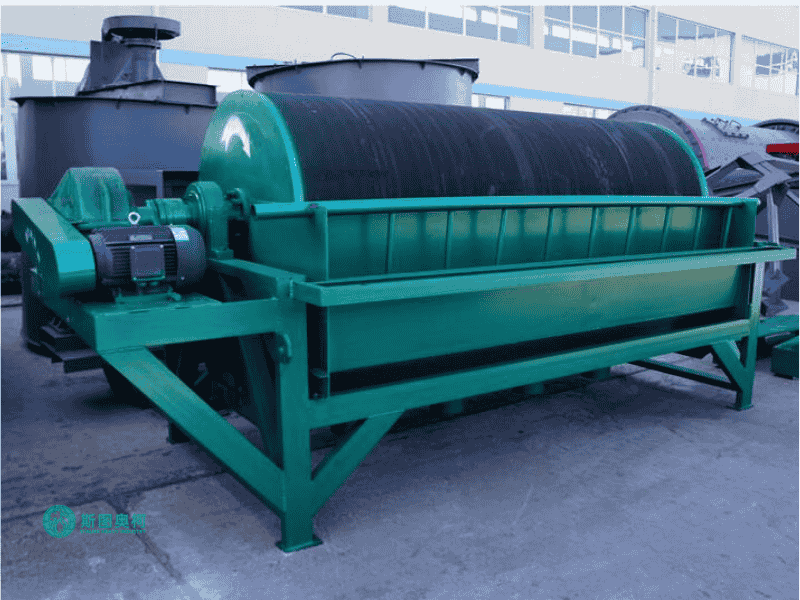

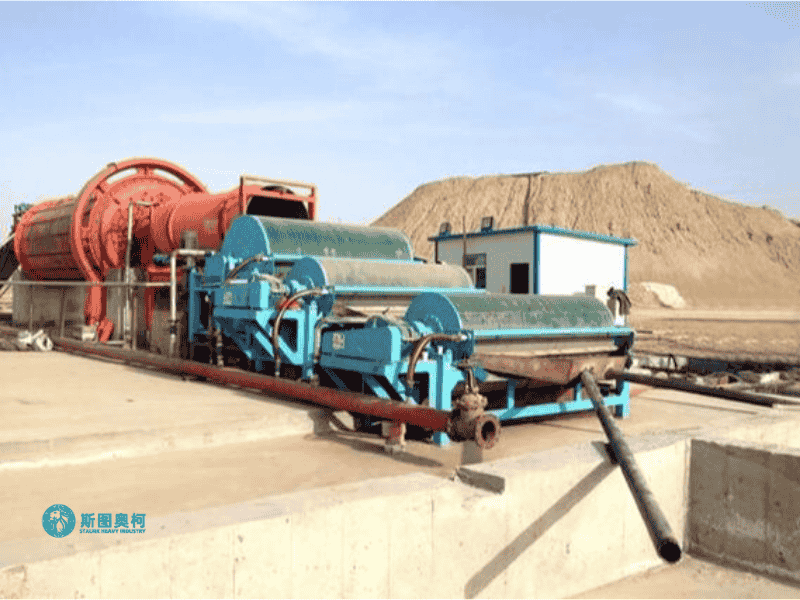

Magnetic Separator

Capacity: 1-150 TPH

Feeding Size: 0.01-300 mm

Recovery Rate: Strong magnetic ore > 95%, weak magnetic ore 70-90%

Handling Materials: Magnetite, titanomagnetite, roasted hematite, manganese ore, etc.

Magnetic separator extracts ferrous minerals (e.g., magnetite, iron scraps) via rotating drums with 0.1–1.5T magnetic fields. Handles 1–300mm dry or 0.01–5mm wet feeds at 1–150t/h, achieving 60–68% Fe concentrate. Ideal for mining and recycling but ineffective for non-magnetic materials.

Advantages

01.

High Efficiency

Achieves 95%+ recovery for magnetite with 0.1-1.5T adjustable fields, upgrading Fe from 30% to 60-68% in single pass.

02.

Dual Processing

Handles both dry (1-300mm) and wet (0.01-5mm) feeds, adapting to diverse ore types and site conditions.

03.

Low Maintenance

Permanent magnet models eliminate power needs; rugged drum design withstands abrasive ores for 10,000+ hours.

04.

Compact Operation

Modular units (1-150t/h) save space versus belt separators, allowing vertical/multi-stage configurations.

How Does A Magnetic Separator Work

1. Material Feeding: Ore (dry/wet) is evenly fed onto the rotating drum surface, where magnetic particles contact the magnetic field (0.1–1.5T).

2. Magnetic Capture: Ferrous minerals (magnetite) are attracted and pinned to the drum, rotating with it due to magnetic force dominance over gravity/centrifugal forces.

3. Separation Zone: As the drum rotates, non-magnetic particles fall freely, while magnetics adhere until passing the neutral zone where they detach into a concentrate chute.

4. Product Discharge: Magnetics are scraped or flushed off as high-grade concentrate; tailings exit via gravity or slurry flow, completing the separation cycle.

Applications

Models

Model | Magnetic Intensity (Gauss) | Capacity (TPH) | Power (kW) | Weight (kg) | Dimensions (L x W x H, mm) | Application |

MS-500 | 5,000 | 10-20 | 1.5 | 800 | 2,000 x 1,000 x 1,500 | Iron removal from fine materials |

MS-1000 | 8,000 | 20-40 | 3.0 | 1,200 | 2,500 x 1,200 x 1,800 | Mineral processing |

MS-1500 | 12,000 | 40-60 | 5.5 | 1,800 | 3,000 x 1,500 x 2,000 | Recycling and waste separation |

MS-2000 | 15,000 | 60-100 | 7.5 | 2,500 | 3,500 x 1,800 x 2,500 | Iron ore beneficiation |

MS-3000 | 20,000 | 100-150 | 11 | 3,500 | 4,000 x 2,000 x 3,000 | Heavy-duty mining applications |