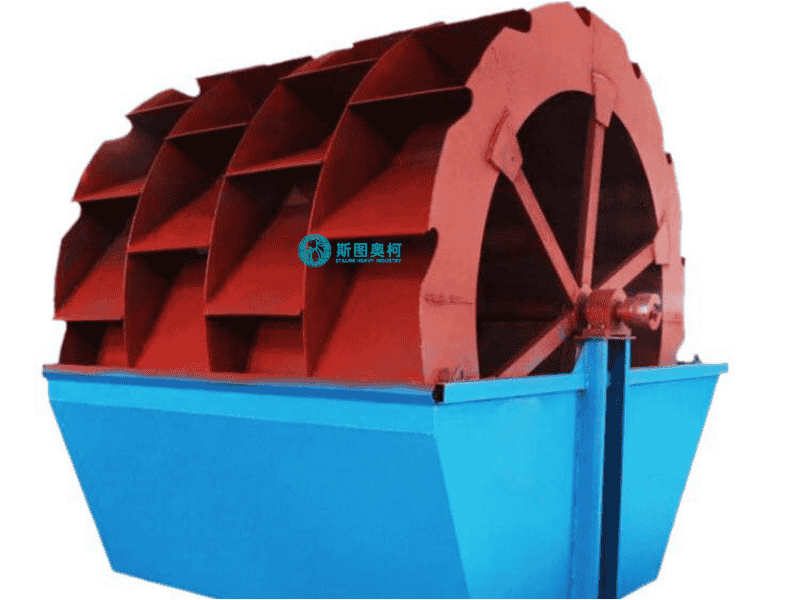

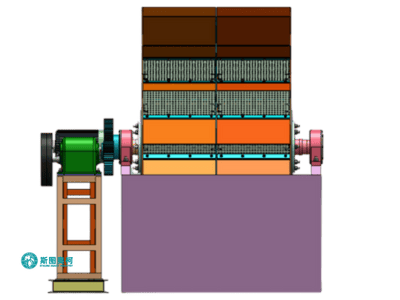

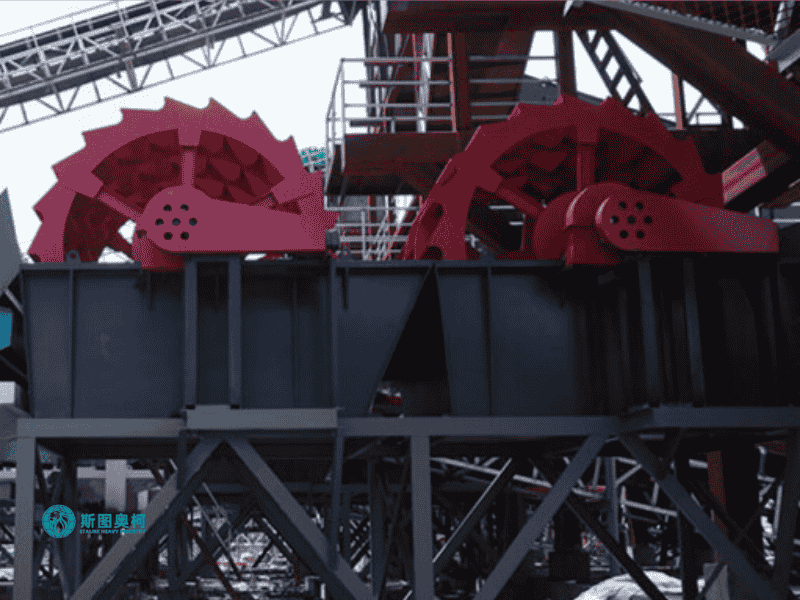

Bucket Wheel Sand Washer

Capacity: 20-300 TPH

Feeding Size: ≤10 mm

Discharging Size: 0.1-5 mm

Handling Materials: 0-10 mm sand, machine-made sand or mineral powder, etc

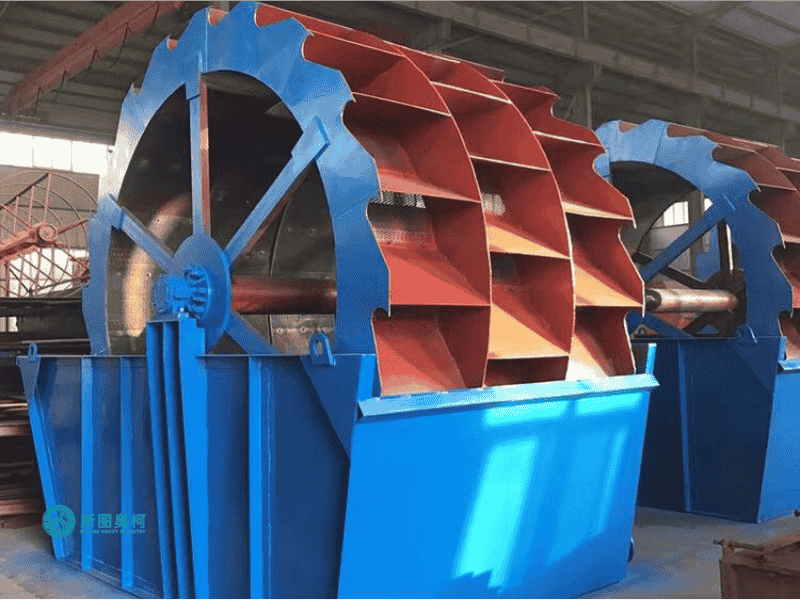

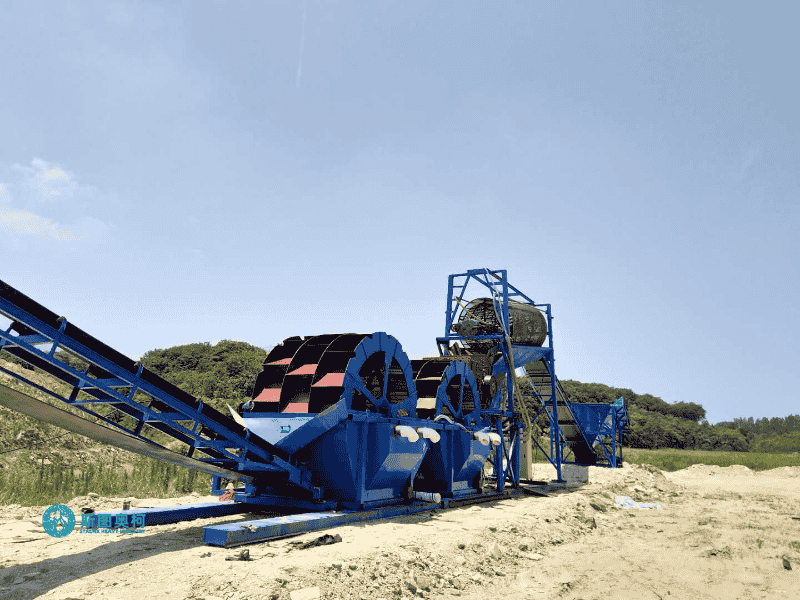

The bucket wheel sand washer is a machine used to clean and separate fine aggregates like sand (0-10mm) by removing clay, dust, and other impurities. It features a rotating bucket wheel that stirs and washes materials with water, ensuring high cleanliness for construction, mining, and concrete applications. With capacities ranging from 20-300 t/h. Its simple structure, durability, and adaptability make it ideal for sand washing, gravel cleaning, and mineral processing operations.

Advantages

01.

High Cleaning Efficiency

Removes 95%+ impurities like clay and dust from 0-10mm sand, ensuring superior material quality for construction and mining applications.

02.

Large Capacity

Processes 20-300 t/h of materials with consistent performance, ideal for medium to large-scale sand washing operations.

03.

Low Water Use

Optimized water circulation minimizes consumption while maintaining effective cleaning, reducing operational costs and environmental impact.

04.

Durable Structure

Built with wear-resistant materials for long service life, requiring minimal maintenance even in harsh working conditions.

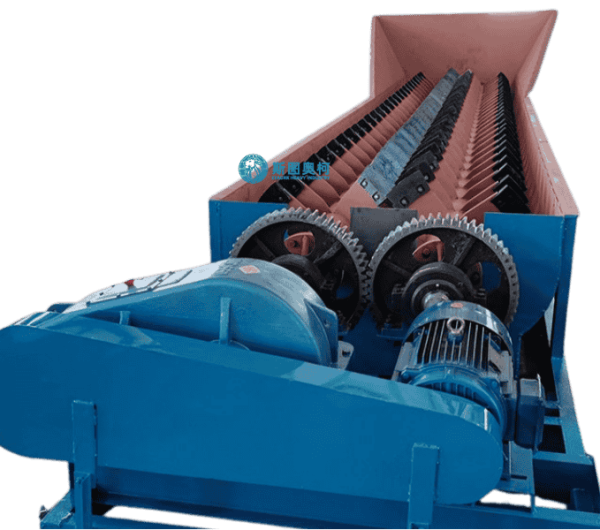

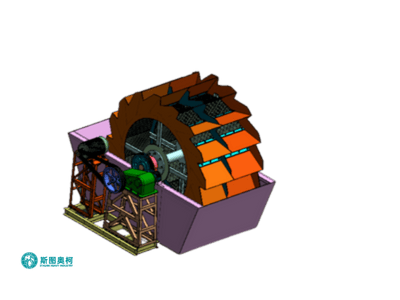

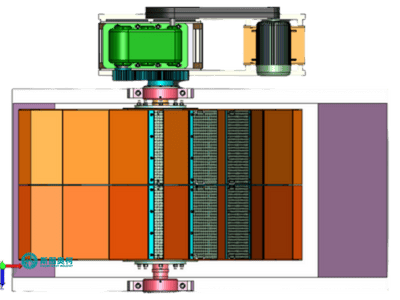

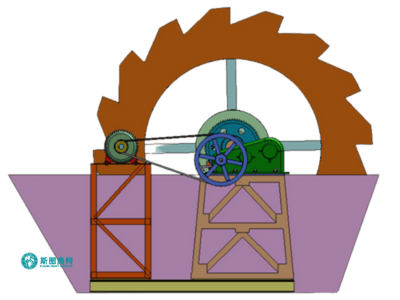

How Does A Bucket Wheel Sand Washer Work

1. Feeding & Mixing: Raw sand (0-10mm) enters with water, forming a slurry for initial impurity separation.

2. Mechanical Scrubbing: Rotating buckets aggressively tumble materials, breaking clay clusters and removing surface contaminants.

3. Separation: Clean sand settles while wastewater carries away suspended clay and dust through overflow weirs.

4. Discharge: Washed sand is elevated by buckets and discharged via chute, completing the cleaning cycle.

Applications

Models

Model | Capacity (t/h) | Wheel Diameter (mm) | Motor Power (kW) | Weight (t) | Water Consumption (m³/h) |

XS-2600 | 50–100 | 2600 | 7.5–11 | 5.8 | 50–80 |

XS-3000 | 80–150 | 3000 | 11–15 | 7.2 | 80–120 |

XS-3500 | 120–200 | 3500 | 15–18.5 | 9.5 | 100–150 |

LZ-30 | 30–50 | 2200 | 5.5 | 4.2 | 30–50 |

2LZ-60 | 60–100 | 2500 | 7.5 | 6.0 | 50–70 |

LX-2000 | 80–120 | 2000 (dual-wheel) | 11×2 | 8.5 | 70–100 |