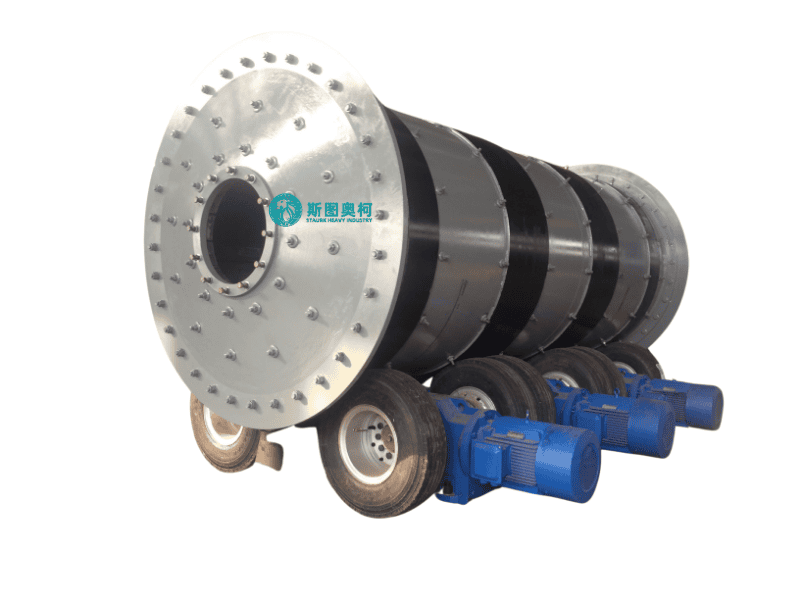

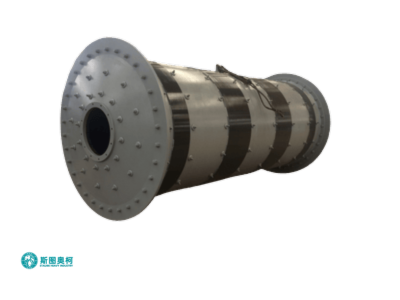

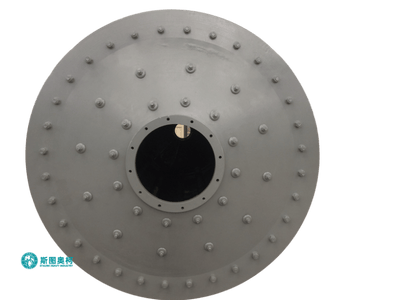

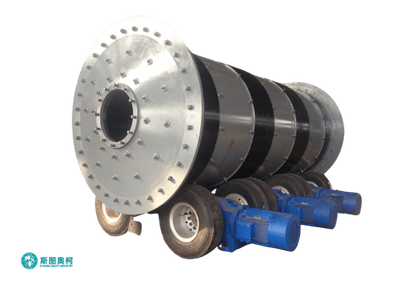

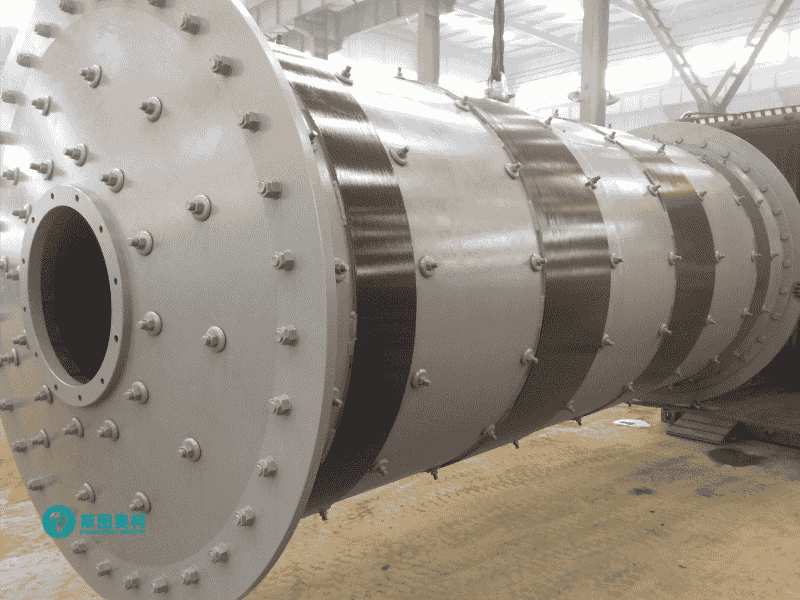

Tire Mill

Capacity: 10-300TPH

Feeding Size: ≤25mm

Discharging Size: 45-150μm

Handling Materials: Cement clinker, ore, limestone, and slag, etc.

Tire mill processes cement clinker, ores, and slag (feed ≤25mm) into 45-150μm powder. Its tire-based transmission cuts energy use by 10-15% versus gear drives while handling 10-300t/h capacity. Ideal for large-scale cement/mining plants needing reliable, low-maintenance operation.

Advantages

01.

Energy Efficient

Reduces power consumption by 10-15% compared to gear-driven mills through optimized tire rotation and minimized mechanical friction losses.

02.

High Capacity

Handles large-scale production (10-300t/h) with stable operation, ideal for cement plants and mining applications requiring continuous grinding.

03.

Low Maintenance

Eliminates traditional girth gears, reducing lubrication points and wear part replacements by 30-40%, lowering operational downtime.

04.

Durable Design

Robust tire support system extends service life by 20-30%, even under heavy-load conditions with abrasive materials.

How Does A Tire Mill Work

1.Material Feeding: Pre-crushed materials (≤25 mm) enter the rotating drum via a sealed inlet, mixing with steel balls (30-100 mm diameter) as grinding media.

2. Tire-Driven Rotation: Motor-powered tires (instead of gears) rotate the drum at 15-25 RPM, lifting materials and balls via centrifugal force for cascading impact.

3. Grinding Action: Cascading balls crush particles through impact and attrition, while the tire system’s low friction maintains consistent torque for stable grinding.

4. Product Discharge: Ground powder (45-150μm) exits through discharge grates, with oversize particles recirculated. Closed-circuit systems add separators for finer grading (≤30μm).

Applications

Models

Model | Roller Diameter (mm) | Roller Width (mm) | Rotation Speed (r/min) | Capacity (t/h) | Power (kW) | Weight (t) |

TY-1200 | 1200 | 450 | 30-35 | 10-15 | 55 | 12 |

TY-1300 | 1300 | 500 | 28-32 | 15-20 | 75 | 15 |

TY-1400 | 1400 | 550 | 25-30 | 20-25 | 90 | 18 |

TY-1500 | 1500 | 600 | 22-28 | 25-30 | 110 | 22 |

TY-1600 | 1600 | 650 | 20-25 | 30-35 | 132 | 26 |

TY-1700 | 1700 | 700 | 18-22 | 35-40 | 160 | 30 |

TY-1800 | 1800 | 750 | 16-20 | 40-45 | 185 | 35 |

TY-2000 | 2000 | 800 | 14-18 | 45-50 | 220 | 40 |

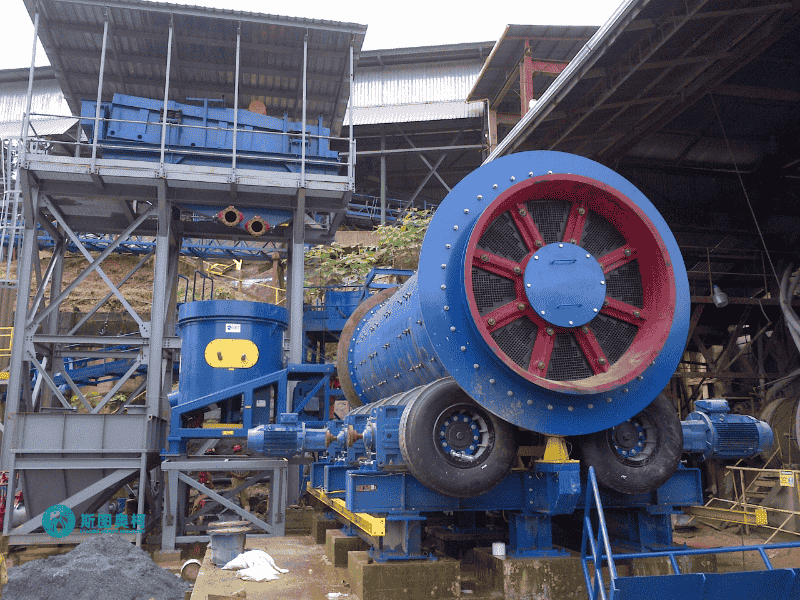

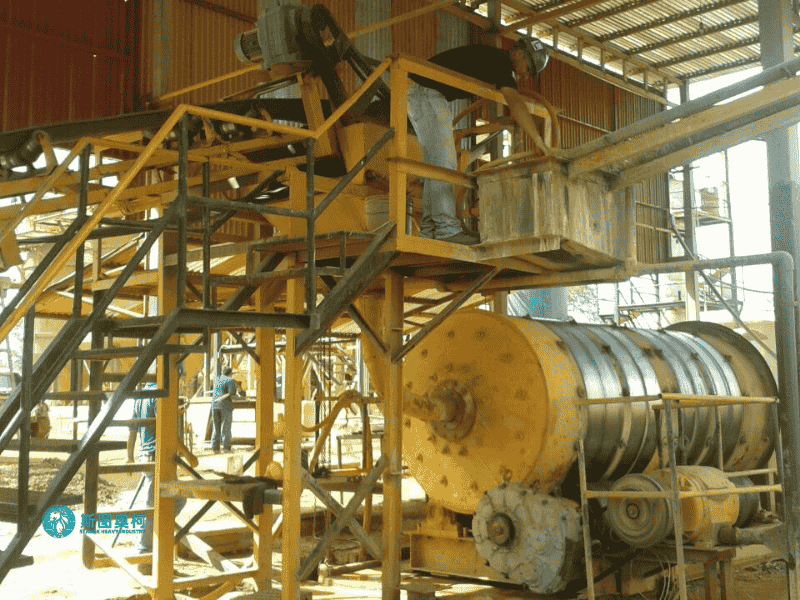

Related Cases

Capacity: 50t/h

Capacity: 50t/h

Capacity: 50t/h