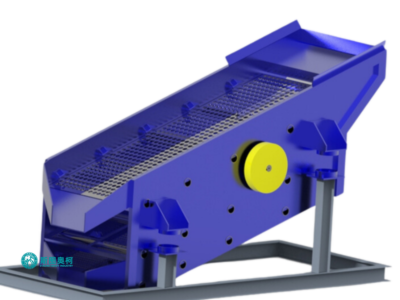

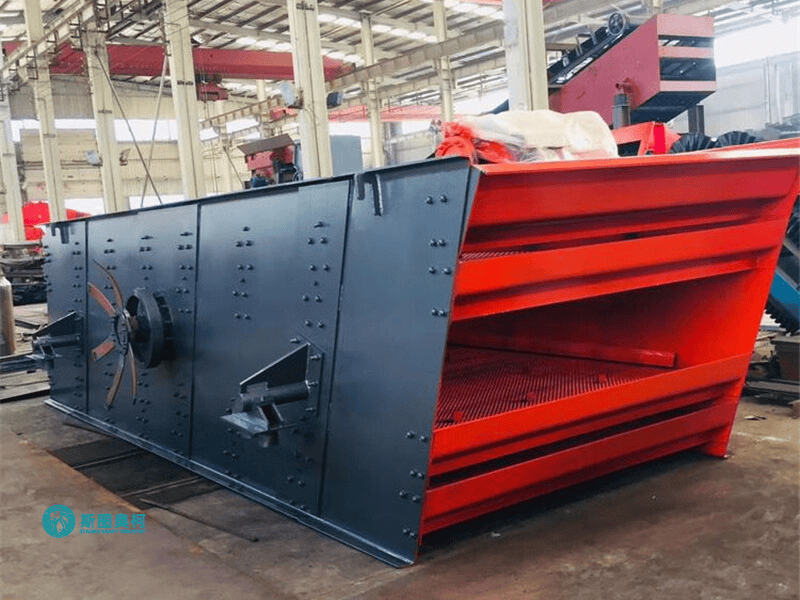

Vibrating Screen

Capacity: 10-500TPH

Feeding Size: ≤300mm

Discharging Size: 0.1-100mm

Handling Materials: Aggregates, minerals, grains, recycled waste, etc.

A vibrating screen sorts and separates granular materials (sand, coal, grains) by size using high-frequency vibrations and layered screens. Ideal for mining, agriculture, and recycling, it offers high capacity (10–500t/h), multi-size grading (0.1–100mm), and efficient dry/wet screening.

Advantages

01.

High Efficiency

Rapid vibration (800-1500 RPM) ensures quick material stratification and screening, boosting throughput up to 500t/h for large-scale operations.

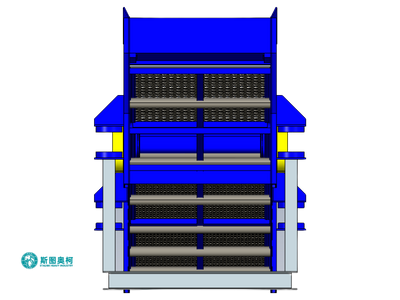

02.

Precise Sizing

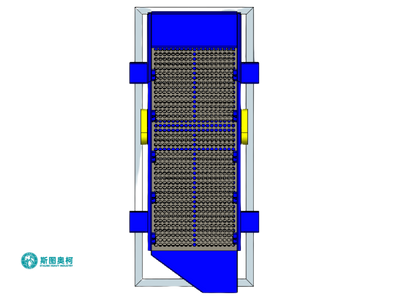

Multi-deck screens (2-4 layers) enable simultaneous grading into 3-5 particle sizes (0.1-100mm) with ±5% accuracy.

03.

Low Maintenance

Sealed bearings and rubber isolators reduce wear, offering 10,000+ hours lifespan with minimal lubrication needs.

04.

Adaptable Design

Handles dry/wet materials (add spray bars) and custom screen types (polyurethane/wire mesh) for diverse industries.

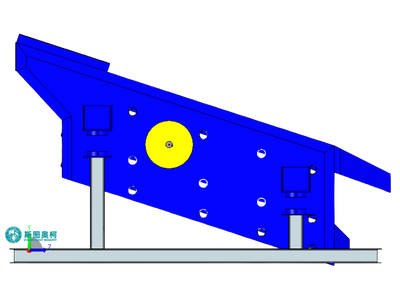

How Does Vibrating Screen Work

1. Material Feeding: Bulk materials are evenly fed onto the inclined screen surface through a hopper or conveyor belt.

2. Vibration Stratification: High-frequency vibrations (800-3600 RPM) from eccentric weights or motors propel particles upward while gravity pulls them downward, creating stratification by size.

3. Size Separation: Smaller particles pass through screen apertures (mesh size 0.1-100mm), while larger particles travel across the screen to the discharge end. Multi-deck designs enable simultaneous multi-grade sorting.

4. Discharge & Recycling: Screened fractions exit via separate chutes; oversize materials may return for re-crushing. Optional air suction or spray systems enhance fine particle separation.

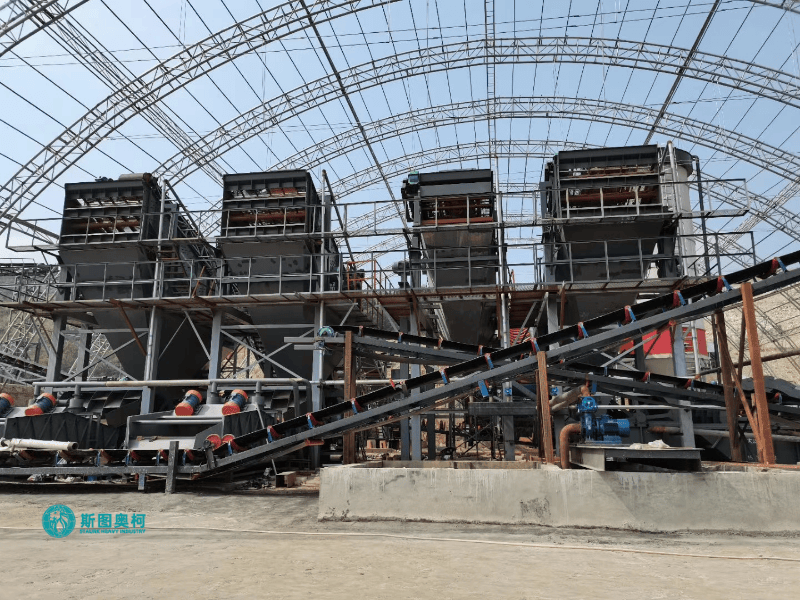

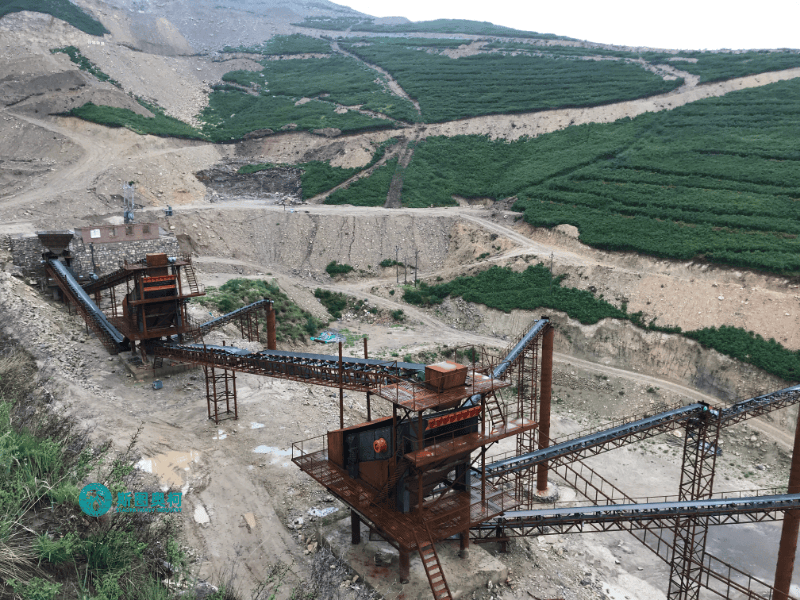

Applications

Models

Model | Screen Size (mm) | Deck Layers | Mesh Size (mm) | Power (kW) | Capacity (t/h) | Vibration Frequency (rpm) | Amplitude (mm) |

VS-1000 | 1000x2000 | 1-3 | 0.1-50 | 1.5-3.0 | 5-20 | 1500 | 4-6 |

VS-1200 | 1200x2400 | 1-3 | 0.1-50 | 2.2-4.0 | 10-30 | 1500 | 4-6 |

VS-1500 | 1500x3000 | 1-3 | 0.1-50 | 3.0-5.5 | 20-50 | 1500 | 4-6 |

VS-1800 | 1800x3600 | 1-3 | 0.1-50 | 4.0-7.5 | 30-80 | 1500 | 4-6 |

VS-2000 | 2000x4000 | 1-3 | 0.1-50 | 5.5-11.0 | 50-120 | 1500 | 4-6 |

VS-2400 | 2400x4800 | 1-3 | 0.1-50 | 7.5-15.0 | 80-200 | 1500 | 4-6 |