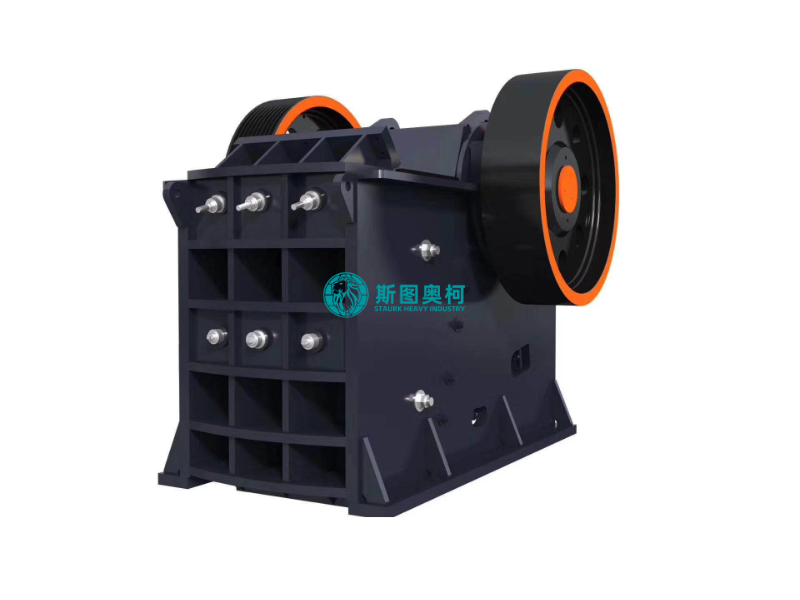

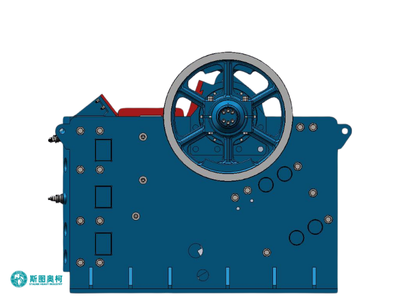

Jaw Crusher

Capacity: 3-600TPH

Feeding Size: ≤1200mm

Discharging Size: 15-200mm

Handling Materials: Limestone, iron ore, steel slag, phosphate ore, copper ore, silicon ore, quartz ore,etc.

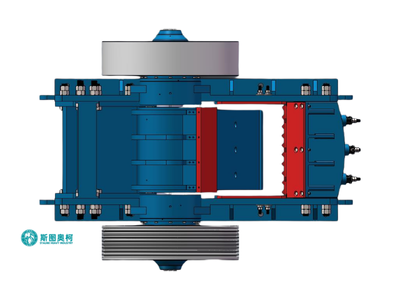

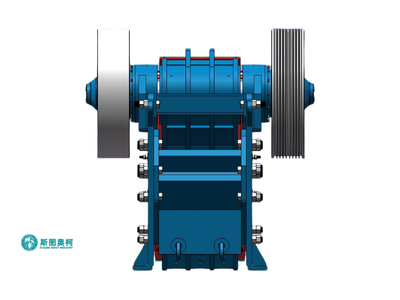

A jaw crusher is a robust and versatile heavy-duty equipment which widely used in mining, construction, and recycling industries. It is designed to crush large rocks, ores, and other hard materials into smaller, more manageable pieces through a process of compression. The machine consists of two jaw plates: a fixed jaw and a movable jaw. The movable jaw exerts force on the material by pressing it against the fixed jaw, effectively crushing it into smaller sizes.

Advantages

01.

High Crushing Efficiency

providing high crushing efficiency and consistent performance.

02.

Durable Construction

Built with robust materials, jaw crushers are highly durable and capable of withstanding harsh working conditions in mining and construction environments.

03.

Adjustable Discharge Opening

can be easily adjusted to control the size of the crushed material, ensuring the final product meets specific requirements.

04.

Low Operating Costs

With their efficient design and minimal maintenance requirements, jaw crushers offer low operating costs and high return on investment.

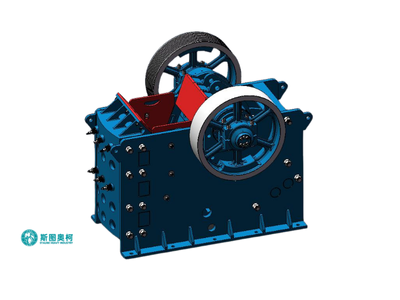

How Does A Jaw Crusher Work

1.Material Feeding: Large rocks or materials are fed into the crushing chamber from the top of the machine.

2.Compression: The movable jaw moves towards the fixed jaw, compressing the material between the two plates. This action breaks the material into smaller pieces.

3.Release and Repeat: The movable jaw then moves away from the fixed jaw, allowing the crushed material to fall further down the chamber. This process repeats cyclically until the material is small enough to pass through the discharge opening at the bottom.

4.Discharge: The crushed material exits the crusher through the discharge opening, ready for further processing or use.

Applications

Models

Model | Feed Opening Size (mm) | Max Feed Size (mm) | Capacity (t/h) | Motor Power (kw) | Discharge Opening Range (mm) | Overall Dimensions (L×W×H, mm) | Weight (t) |

PE-150×250 | 150×250 | 125 | 1-3 | 5.5 | 10-40 | 896×745×935 | 1.5 |

PE-250×400 | 250×400 | 210 | 5-20 | 15 | 20-60 | 1430×1310×1340 | 3 |

PE-400×600 | 400×600 | 340 | 16-65 | 30 | 40-100 | 1700×1732×1653 | 7 |

PE-500×750 | 500×750 | 425 | 45-100 | 55 | 50-100 | 2035×1921×2000 | 12 |

PE-600×900 | 600×900 | 500 | 50-120 | 55-75 | 65-160 | 2290×2206×2370 | 17 |

PE-750×1060 | 750×1060 | 630 | 110-320 | 90-110 | 80-140 | 2655×2302×3110 | 29 |

PE-900×1200 | 900×1200 | 750 | 220-450 | 110-132 | 95-165 | 3800×3166×3045 | 52 |

PEX-150×750 | 150×750 | 120 | 8-25 | 15 | 18-48 | 1200×1530×1060 | 3.8 |

PEX-250×1000 | 250×1000 | 210 | 16-52 | 30 | 25-60 | 1560×1950×1390 | 7 |

PEX-300×1300 | 300×1300 | 250 | 16-105 | 55 | 20-90 | 2720×1950×1600 | 15.6 |

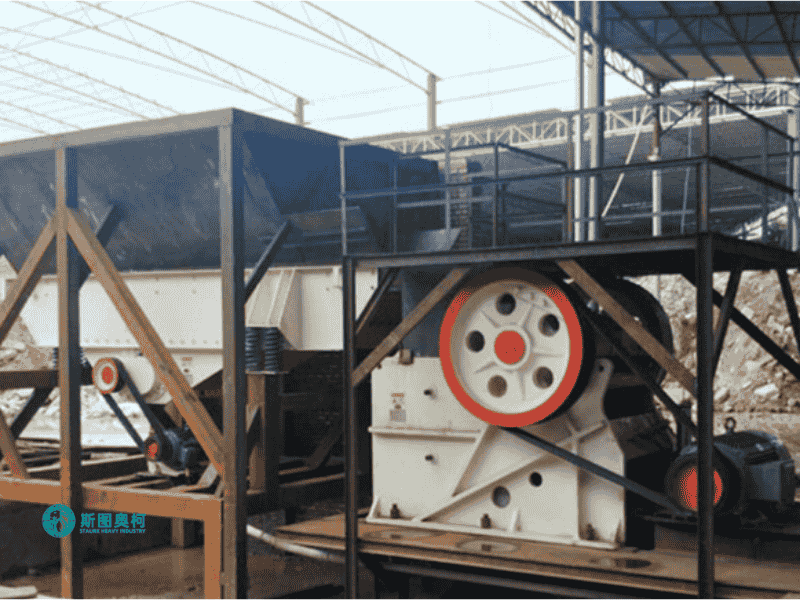

Related Cases

Capacity: 50t/h

Capacity: 50t/h

Capacity: 50t/h