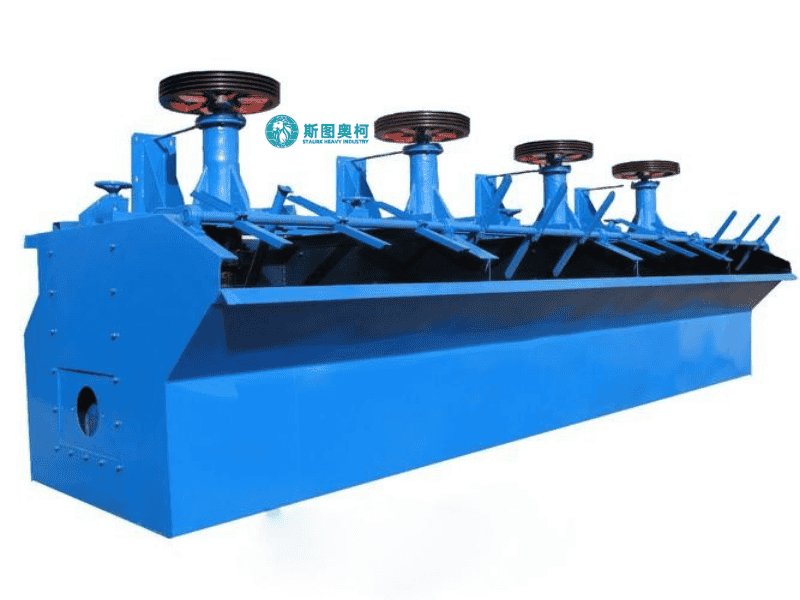

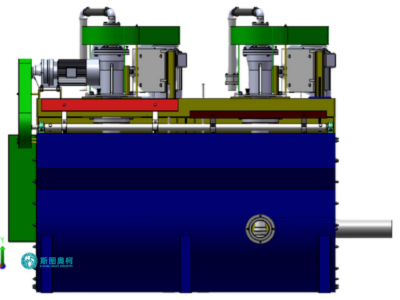

Flotation Machine

Capacity: 0.5–300 m³/cell

Feeding Size: ≤0.3 mm

Discharging Size: 0.01-0.1 mm

Handling Materials: Copper, zinc, lead, nickel and gold, metals and nonmetals, etc.

Flotation machine separates valuable ores (e.g., copper, gold) from gangue using air bubbles and chemicals, handling 0.5-300m³/cell. Ideal for 0.01-0.3mm particles, it achieves 85-95% recovery via adjustable aeration and reagent dosing. Requires slurry density of 25-45% solids for optimal performance.

Advantages

01.

High Selectivity

Targets specific minerals (sulfides) via reagent customization, achieving 85-95% recovery with precise bubble-particle adhesion control.

02.

Scalable Capacity

Modular cells (0.5-300m³ each) enable flexible layouts for 10-10,000t/d plants through series/parallel connections.

03.

Fine Processing

Handles 0.01-0.3mm particles effectively, outperforming gravity/magnetic methods in liberating finely disseminated ores.

04.

Real-Time Control

Automated aeration (0.5-2m³/min·m²) and froth depth adjustments optimize grade/recovery dynamically during operation.

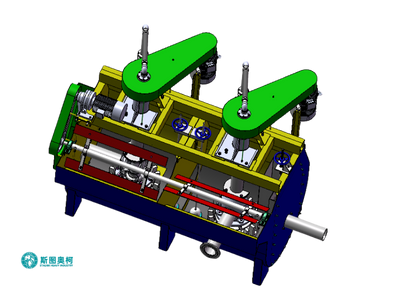

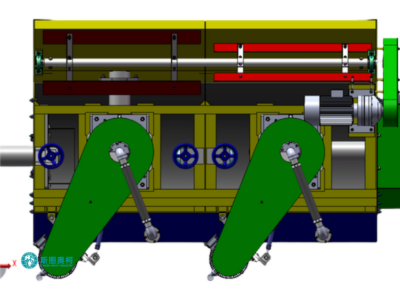

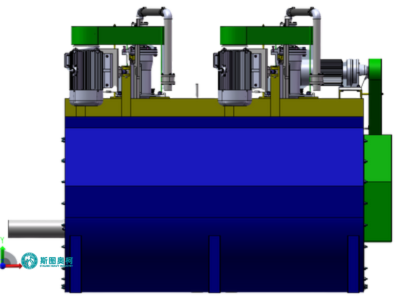

How Does A Flotation Machine Work?

1. Slurry Conditioning: Ore pulp (25-45% solids, 0.01-0.3mm) mixes with reagents (collectors/frothers) to render target minerals hydrophobic.

2. Bubble Generation: Mechanical impellers or external aerators create air bubbles (0.5-2mm diameter), which collide with hydrophobic particles.

3. Mineral Attachment: Hydrophobic particles bond to bubbles, forming stable froth, while hydrophilic gangue sinks (Newtonian separation principle).

4. Product Separation: Froth (concentrate) overflows weirs; tailings discharge from the bottom. Adjustable impeller speed (200-400 RPM) and air rate optimize recovery.

Applications

Models

Model | Volume (m³) | Cell Size (mm) | Impeller Diameter (mm) | Power (kW) | Capacity (m³/min) | Single Cell Weight (kg) |

BF-0.37 | 0.37 | 740×740×750 | 286 | 1.5/1.1 | 0.2–0.4 | 470 |

BF-2.0 | 2.0 | 1400×1450×1120 | 500 | 7.5/1.1 | 1–2 | 1750 |

BF-8 | 8 | 2250×2850×1400 | 760 | 30/1.5 | 4–8 | 4130 |

BF-16 | 16 | 2850×3800×1700 | 850 | 37/1.5 | 8–16 | 8320 |

XCF/KYF-1 | 1 | 1000×1000×1100 | 400/340 | 5.5/4/1.1 | 0.2–1 | 920/1056 |

XCF/KYF-10 | 10 | 2400×2400×2100 | 760/660 | 22/15/1.5 | 3–10 | 4894/4334 |

JRF500/1CL | - | 1700×1400×6200 | - | 7.5 | 0–8 | - |

JRF3224/6R | - | 4592×4240×5344 | - | 135 | 300 | - |

GF-0.35 | 0.35 | 700×700×730 | - | 1.5 | 0.1–0.2 | 470 |

GF-16 | 15 | 2850×3800×1700 | - | 45 | 3–8 | 8320 |

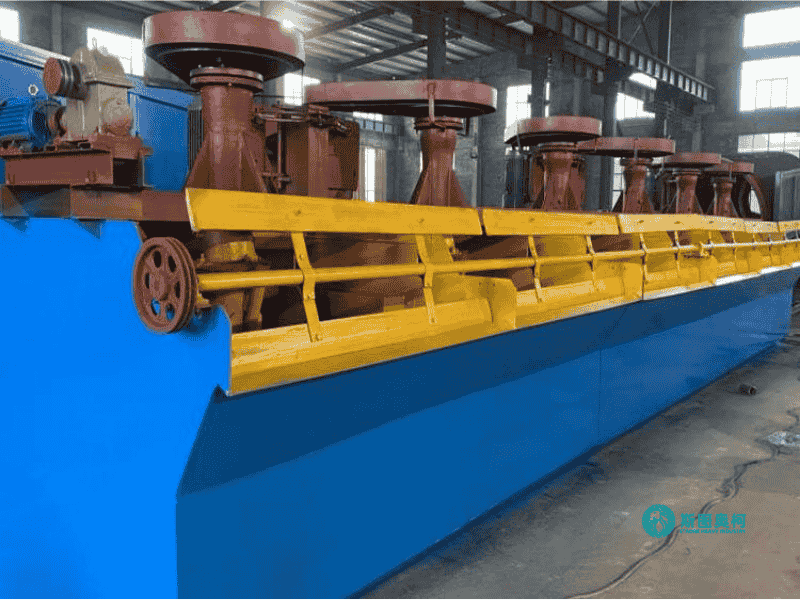

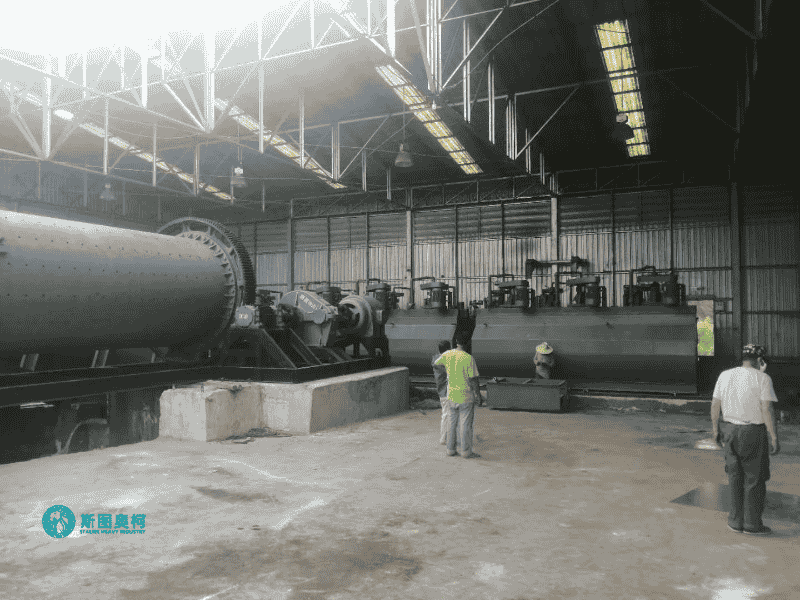

Related Cases

Capacity: 50t/h

Capacity: 50t/h

Capacity: 50t/h