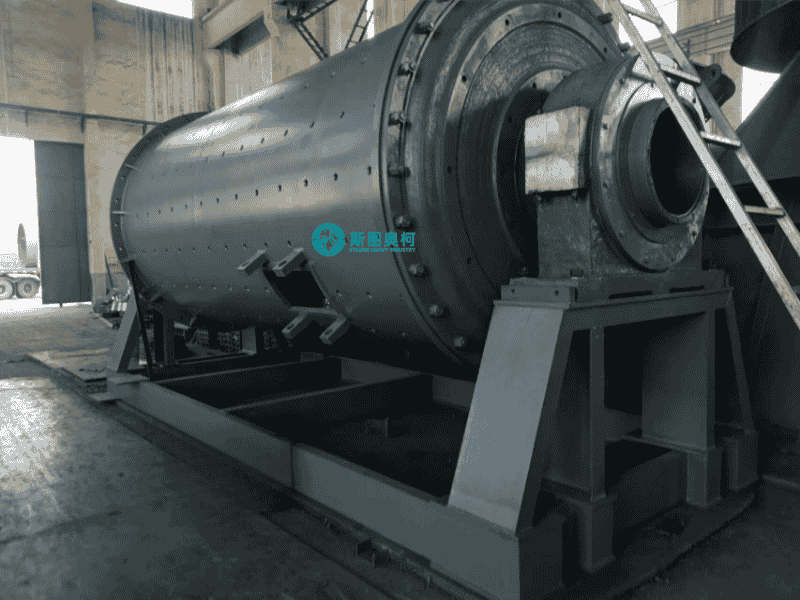

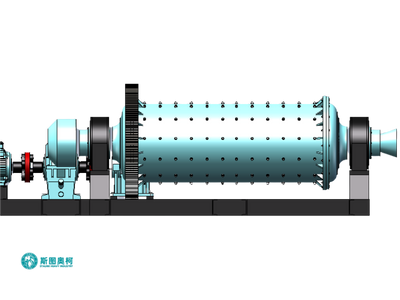

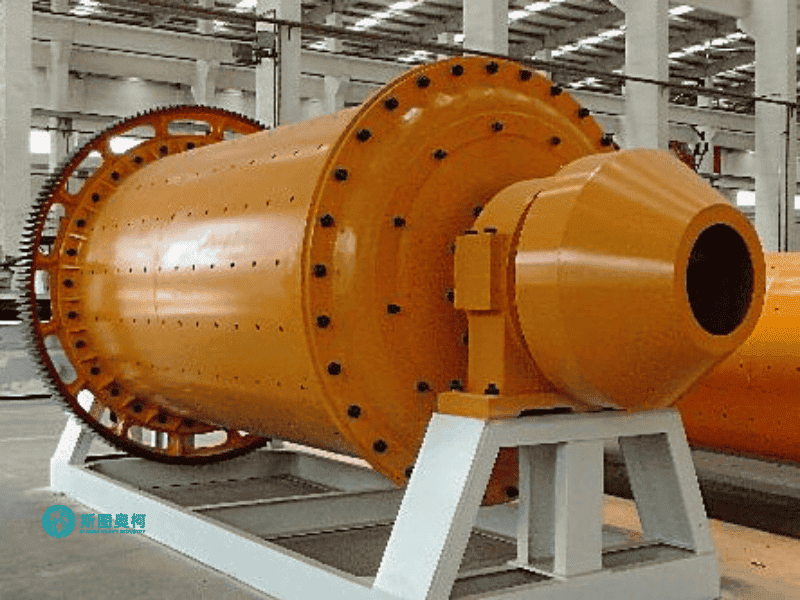

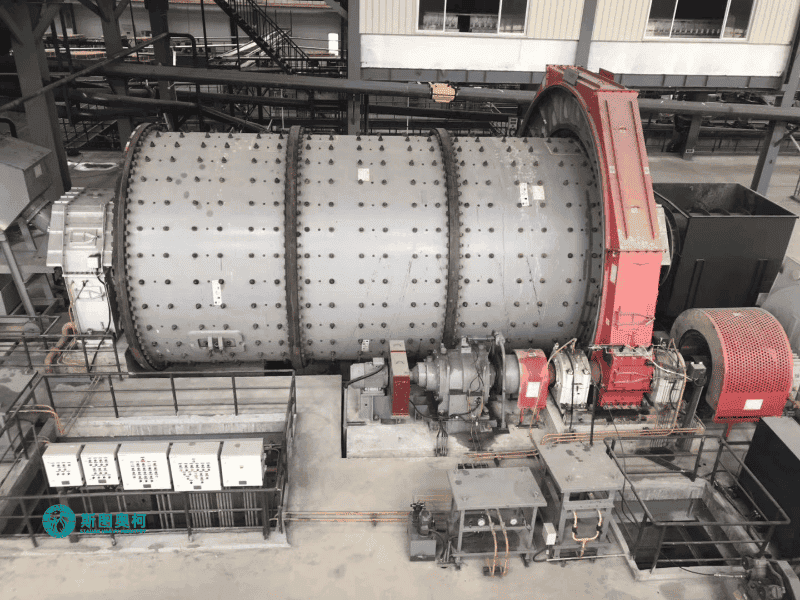

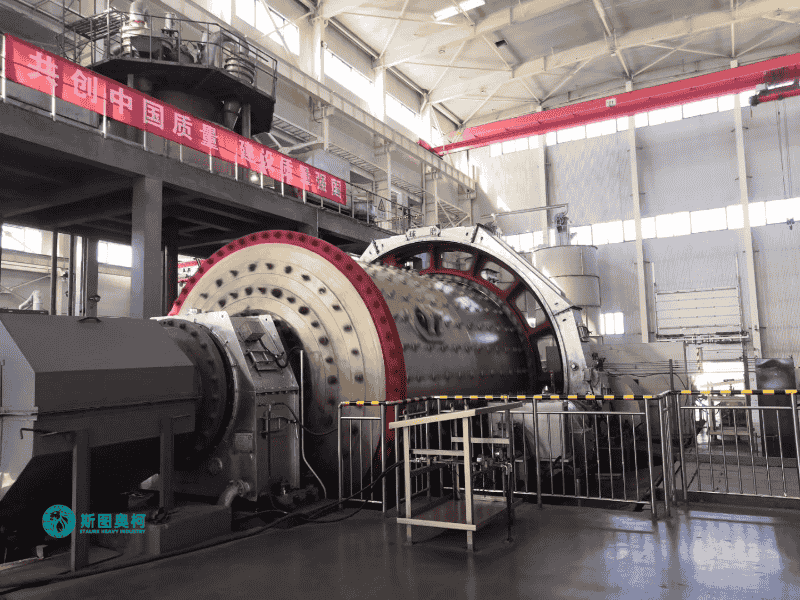

Energy Saving Ball Mill

Capacity: 5-150TPH

Feeding Size: ≤25mm

Discharging Size: 45-150μm

Handling Materials: Cement clinker, ores, slag, limestone, etc.

Energy saving ball mill processes medium-hard materials (e.g., cement, ores) into 45-150μm powder while cutting energy use by 15-30%. Key features include optimized rotating design, wear-resistant liners, and optional pre-grinding systems for higher efficiency. Ideal for mining and building materials industries.

Advantages

01.

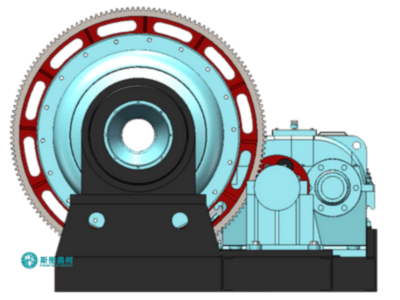

Energy Efficient

Reduces power consumption by 15-30% through optimized drive systems and rolling bearings, lowering operational costs significantly.

02.

Wide Applicability

Handles diverse materials (ores, cement, slag) with hardness up to 9 Mohs, adapting to dry/wet grinding modes.

03.

Precise Grinding

Adjustable media (steel balls/segments) and speed control achieve target fineness (45-150μm) with ±5% consistency.

04.

Low Maintenance

Wear-resistant liners and modular design extend service life by 40%, minimizing downtime for replacements.

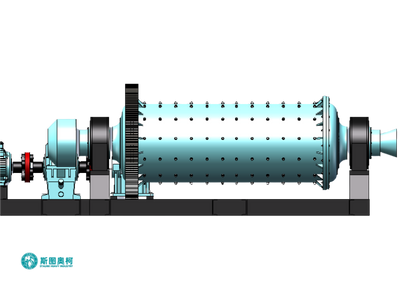

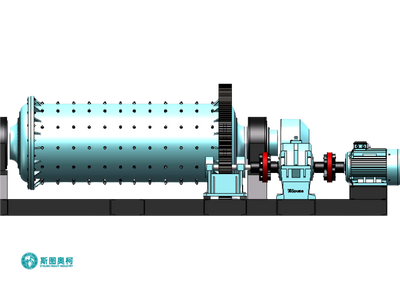

How Does A Energy Saving Ball Mill Work?

1.Material Feeding: Crushed raw materials (≤25mm) enter the rotating drum through a sealed inlet, mixed with grinding media (steel balls/segments).

2. Cascading Motion: The drum's rotation lifts materials and media, creating impact (crushing) and attrition (grinding) forces as they cascade downward.

3. Particle Refinement: Repeated collisions reduce particles to 45-150μm; internal classifying liners separate fines from coarse fragments for continuous processing.

4. Discharge & Recycling: Ground powder exits via discharge grate, while oversize particles circulate back. Closed-circuit systems add air classifiers for ultra-fine products (≤30μm).

Applications

Models

Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Rotation Speed (rpm) | Power (kW) | Capacity (t/h) | Grinding Media Load (t) | Weight (t) |

MQG-900 | 900 | 1800 | 36 | 18.5 | 0.5-2.0 | 1.5 | 5.6 |

MQG-1200 | 1200 | 2400 | 32 | 30 | 1.0-3.0 | 2.7 | 12.5 |

MQG-1500 | 1500 | 3000 | 29 | 45 | 1.5-4.5 | 5.0 | 17.8 |

MQG-1830 | 1830 | 3600 | 25 | 95 | 3.0-7.0 | 8.0 | 28.0 |

MQG-2100 | 2100 | 3000 | 23 | 155 | 4.0-10.0 | 12.0 | 42.0 |

MQG-2700 | 2700 | 3600 | 21 | 400 | 10.0-20.0 | 20.0 | 85.0 |