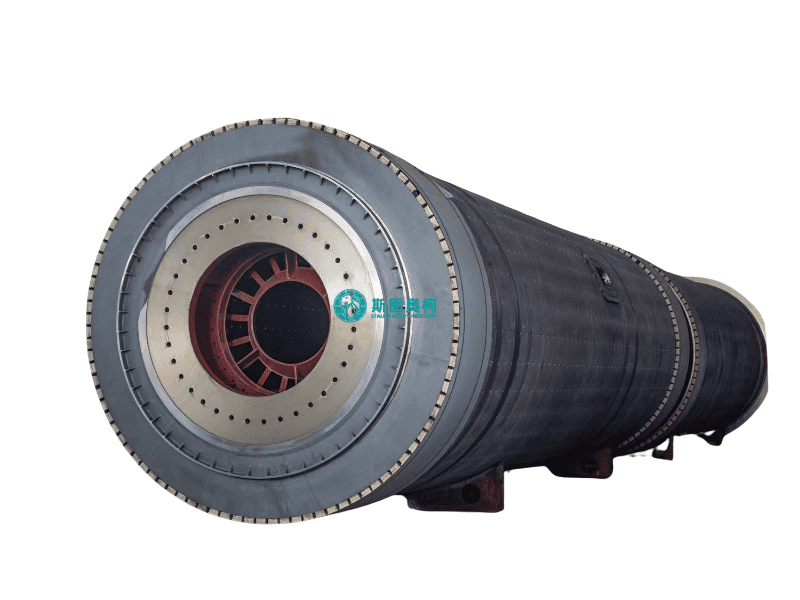

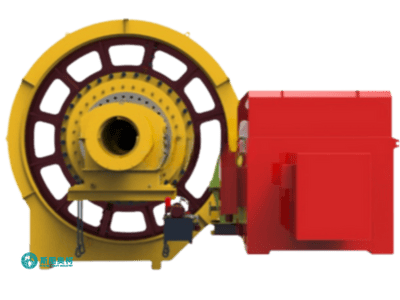

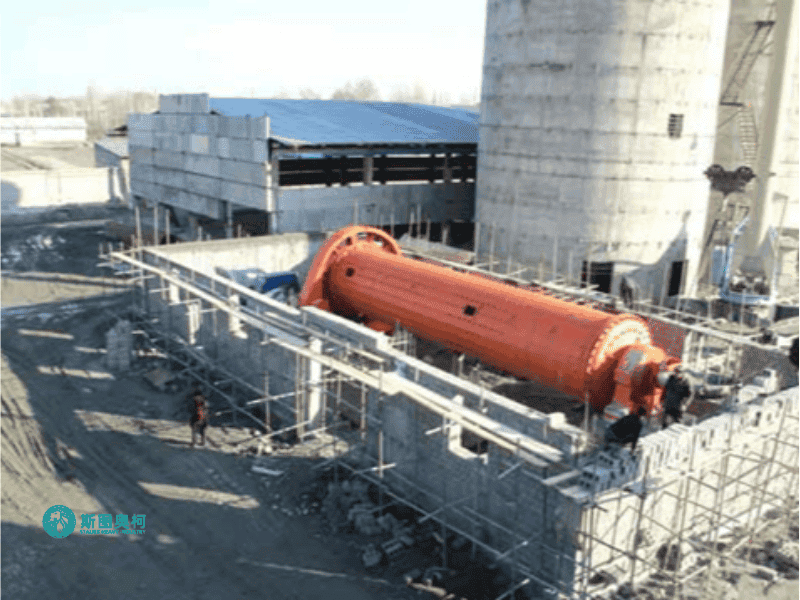

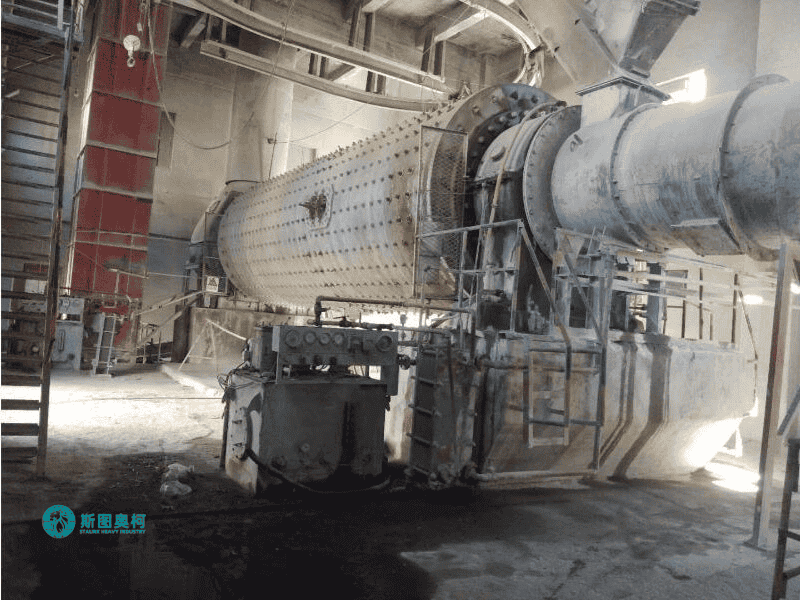

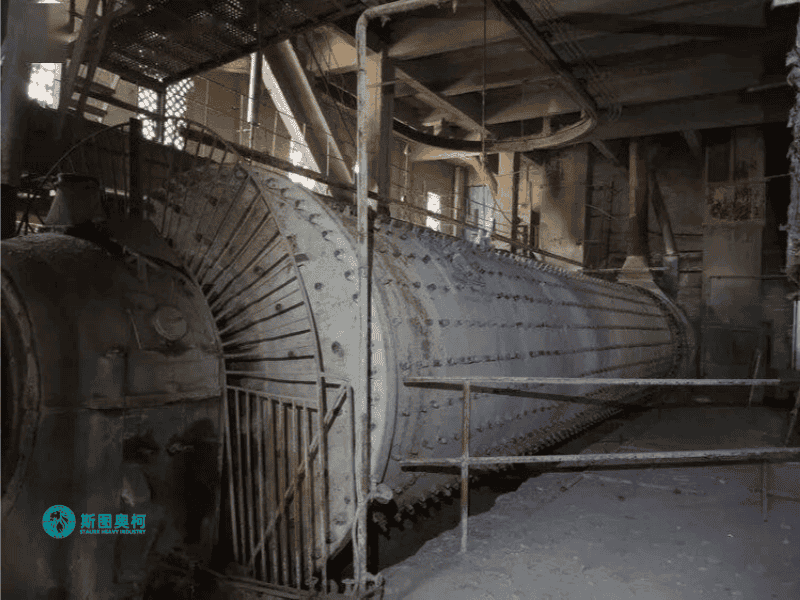

Cement Mill

Capacity: 20-200TPH

Feeding Size: ≤25mm

Discharging Size: ≤20μm

Handling Materials: Limestone, iron ore, steel slag, phosphate ore, copper ore, silicon ore, quartz ore,etc.

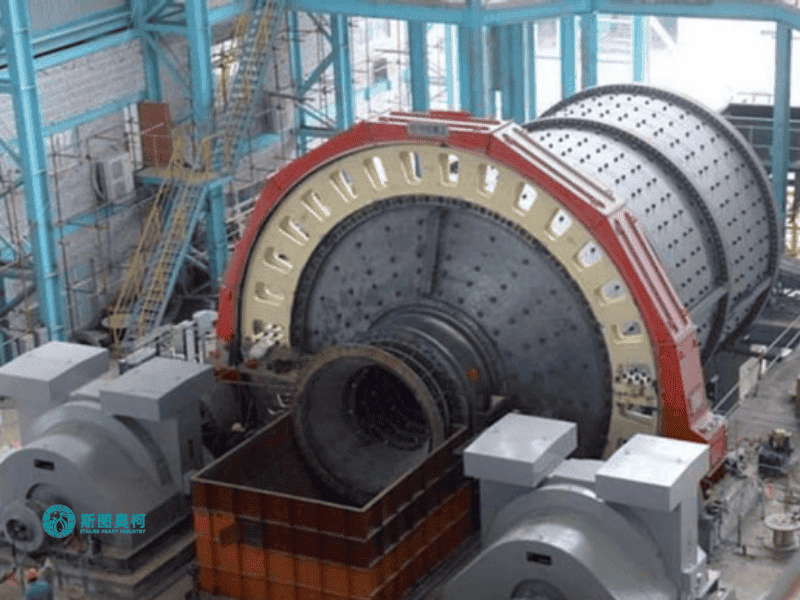

A cement mill grinds clinker, gypsum, and additives into fine powder (80μm residue ≤5%). Key for cement production, it handles ≤25mm feed and achieves 20-200t/h output. Cement mills are used, often with pre-grinding systems (e.g., roller press) to boost efficiency. Closed-circuit designs enhance particle control.

Advantages

01.

High Capacity

Handles 20-200t/h output, scalable via pre-grinding (roller press) or closed-circuit systems for large-scale production.

02.

Precise Fineness

Adjustable grinding media and classifiers ensure 80μm residue ≤5% or customized Blaine (300-600m²/kg) for diverse cement grades.

03.

Material Flexibility

Processes clinker, slag, fly ash, and additives, adapting to composite cement formulations with moisture ≤1.5%.

04.

Energy Options

Cement mills suit intermittent operation; vertical mills cut 30% energy use but require stable feed size ≤50mm.

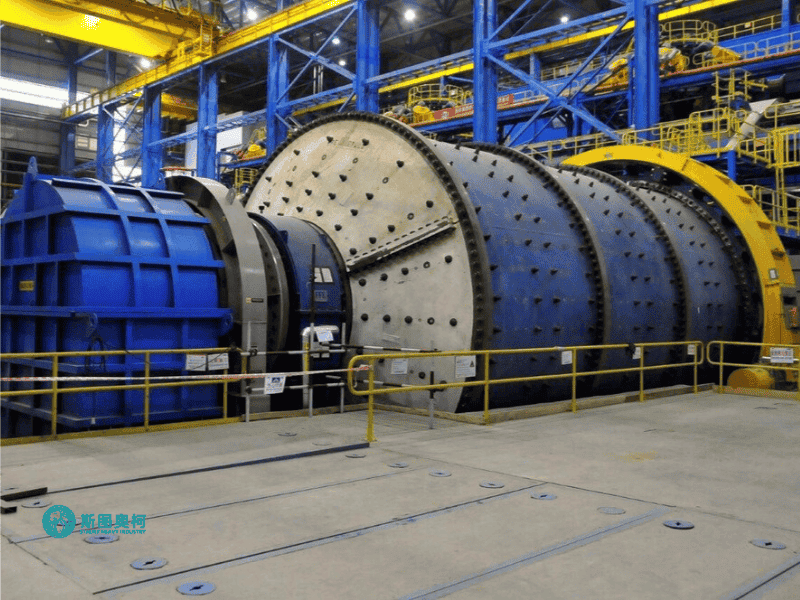

How Does A Cement Mill Work?

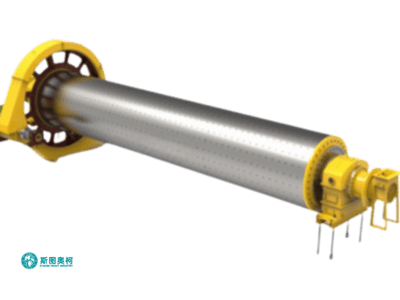

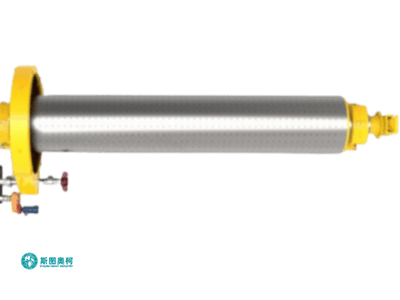

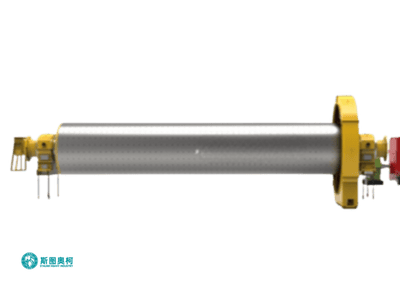

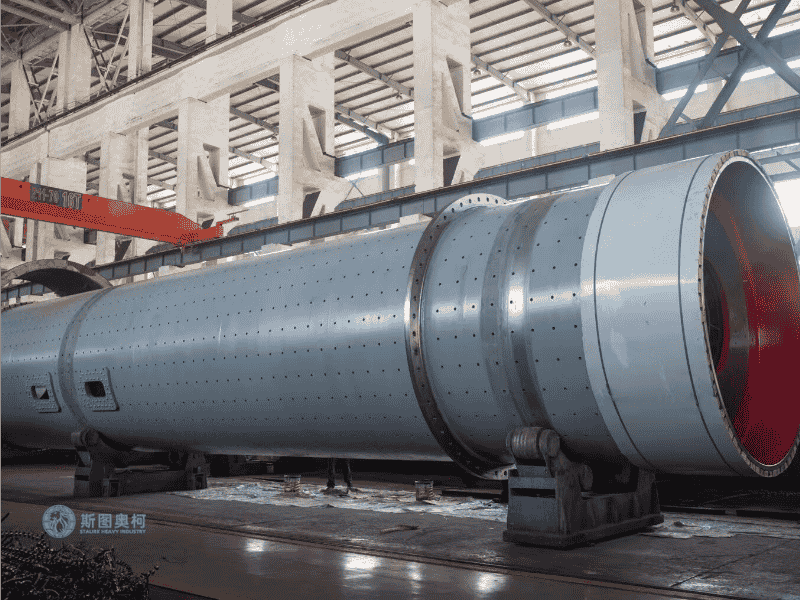

1.Material Feeding: Pre-crushed clinker (≤25mm), gypsum, and additives are fed into the rotating mill chamber via a controlled feed system.

2. Grinding Action: Steel balls (ball mill) or rollers (vertical mill) crush and shear materials into finer particles through impact and attrition forces.

3. Particle Classification: In closed-circuit systems, a separator/recycler returns coarse particles for re-grinding while directing fine powder (≤80μm) onward.

4. Product Discharge: Finished cement exits with Blaine fineness (300-600m²/kg), cooled and collected in silos via dust filters for quality control.

Applications

Models

Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Rotation Speed (rpm) | Power (kW) | Capacity (t/h) | Grinding Media Load (t) | Weight (t) |

CM-2.2x7.5 | 2200 | 7500 | 21 | 380 | 15-20 | 35 | 85 |

CM-2.4x8 | 2400 | 8000 | 20 | 500 | 20-25 | 45 | 110 |

CM-2.6x10 | 2600 | 10000 | 19 | 800 | 30-35 | 60 | 150 |

CM-3.0x11 | 3000 | 11000 | 18 | 1250 | 40-50 | 80 | 200 |

CM-3.2x13 | 3200 | 13000 | 17 | 1600 | 50-60 | 100 | 250 |

CM-3.8x13 | 3800 | 13000 | 16 | 2500 | 70-80 | 120 | 350 |