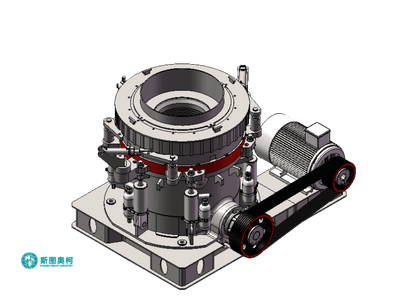

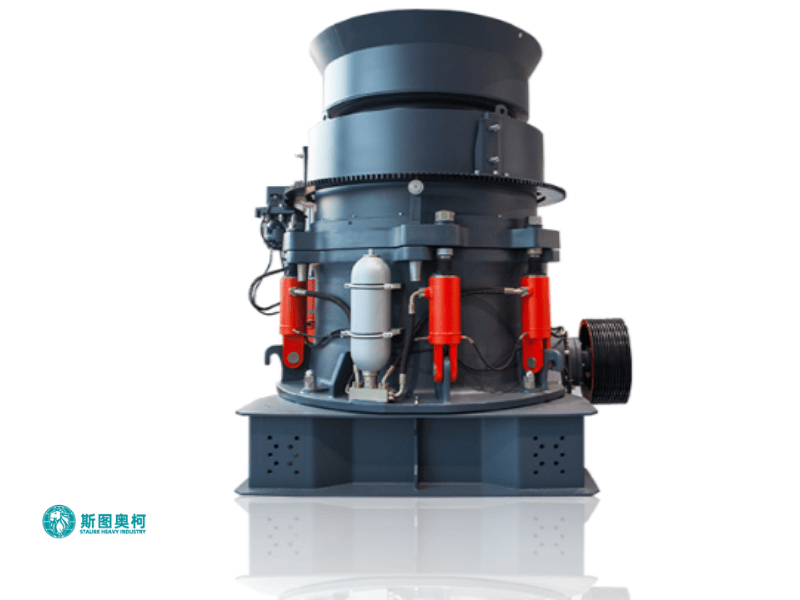

Cone Crusher

Capacity: 45-600TPH

Feeding Size: ≤275mm

Discharging Size: 3-60mm

Handling Materials: Iron ore, copper ore, gold ore, granite, basalt, limestone, crushed stone, gravel, quartz, feldspar, etc.

A cone crusher efficiently crushes large rocks into smaller sizes by compressing material between a rotating cone and a fixed concave. Ideal for secondary and tertiary crushing, it is widely used in mining, quarrying, and aggregate production. Known for high productivity, reliability, and uniform output, it ensures consistent particle shape for various industrial applications.

Advantages

01.

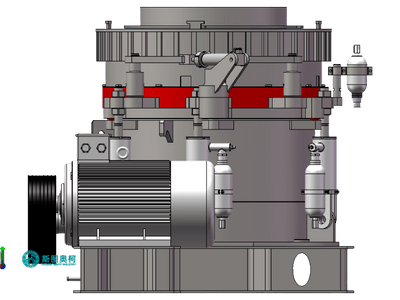

High Crushing Efficiency

Laminated crushing principle ensures high output with low energy consumption.

02.

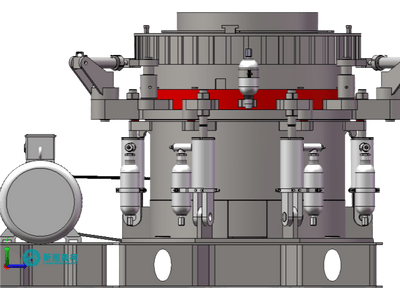

Uniform discharging Size

Precise discharge control produces well-shaped, cubical end products.

03.

Reliable Operation

Hydraulic protection system prevents overload and reduces downtime.

04.

Wide Adaptability

Capable of crushing medium-to-hard ores, rocks, and construction aggregates.

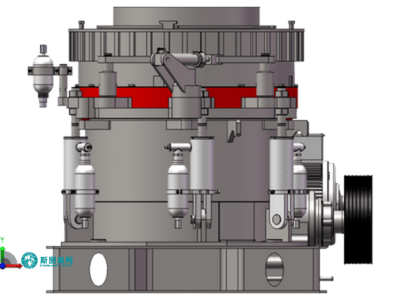

How Does A Cone Crusher Work?

1.Compression Crushing: Material is squeezed between a rotating mantle and stationary concave liner, breaking rocks through compressive force.

2.Eccentric Movement: The gyrating mantle, driven by an eccentric assembly, creates a crushing action with each rotation.

3.Graded Discharge: Crushed material exits through the adjustable discharge gap, determining final particle size.

4.Hydraulic Adjustment: Modern models use hydraulic systems to safely adjust crushing settings and clear blockages.

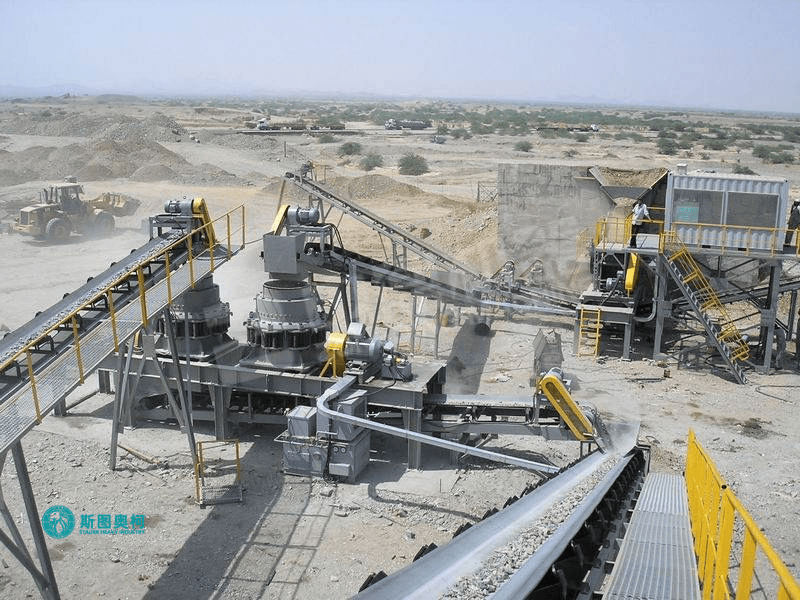

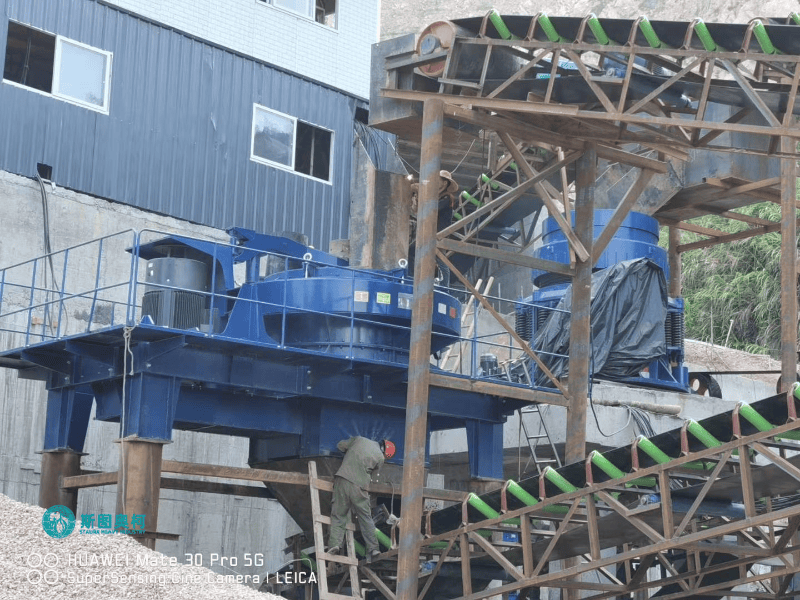

Applications

Models

Model | Max Feed Size (mm) | Capacity (t/h) | Power (kW) | Weight (t) | Closed Side Setting (mm) | Application |

CS75 | 115 | 45-91 | 75 | 12 | 13-38 | Medium crushing |

CS160 | 178 | 120-250 | 160 | 27 | 16-38 | Medium to large crushing |

HPC220 | 275 | 150-430 | 220 | 25.6 | 19-38 | High-capacity crushing |

HP300 | 230 | 120-400 | 220 | 16.5 | 10-45 | Mining, quarrying |

GP100 | 150 | 90-450 | 90 | 8.5 | 10-50 | Aggregate production |

CH660 | 275 | 200-600 | 315 | 24.5 | 13-51 | High-performance crushing |